コンクリート・ビームの衝撃特性

衝撃3点曲げ構成におけるコンクリート梁の衝撃試験のニーズが増えています。インストロンは、この試験に関して必要とされる最大エネルギーによって、9450 あるいは 9440 のどちらかを推奨しています。インストロンでは300 mmのスパンを有する特注の取付け具と専用タップインサートを開発し、データ収集用にDASとBluehill Impactソフトウェアを採用しました。

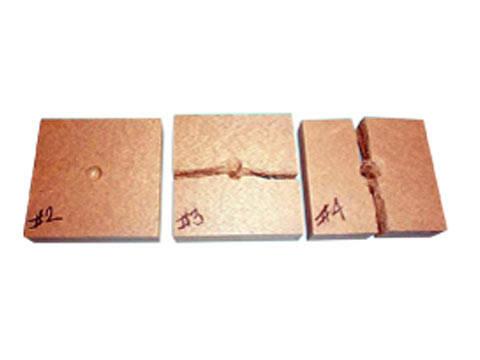

サンプルのサイズは400 mm x 100 mm x 100 mmで、最大速度4.65 m/sまでの試験を行いました。この速度は必要があれば増加させることが可能です。この試験では破壊モードが示されました。またこの試験は、実験室で行うことが可能な試験よりもはるかに大きいエネルギーの試験を必要とする大型構造物を模擬するように意図されました。比較した結果としては、全吸収エネルギー、最大荷重、破壊エネルギーおよび破壊変位がありした。

この9400シリーズは、衝撃荷重を受ける各種材料の性能特性のお客様による測定を手助けするのに非常に適しています。計装化衝撃試験を行うことにより収集される情報は、原材料の混合物における変更が、現実の状況下でどのように性能を発揮するかをお客様が判断することができるデータのベースラインを提供するために用いることができます。他の未だ対応していないスパンと衝撃状況を模擬するため、さまざまな温度において衝撃特性を調査するため環境チェンバーを装備し、また各種取付け具とインサートを用いることにより、さらに広範囲の試験を実施することができます。

9400落錘式衝撃試験機

9400シリーズは、高品質な先進材料開発の最前線に立つお客様、特に高強度で軽量な製品開発を行っている試験室に向け、より速い結果、より少ないエラー、トレーニングに関わる低コスト化を提供するために開発されました。操作手順がシンプルで、事前設定された試験条件および指示付き試験、データの合理化、解析用データの出力、高速度カメラとの親和性などの最新機能を搭載しています。インストロンの落錘衝撃試験機9400シリーズはこれらの機能が備わることで、よりシンプルに。よりスマートに。より安全になります。

- 製品

- 02/05/2020

- 2.16 MB

Bluehill® Impactソフトウェア

Bluehill Impactは、タッチパネル式として設計されています。広い画面のダッシュボードにより、ソフトウェアをよりシンプルでスマートに操作することができます。直観的に分かるアイコンと操作手順により、オペレーター経験のレベルを問わずに使用でき、また、ユーザーのトレーニングが容易になり、驚くほど素早く試験を開始できます。

- 製品

- 08/01/2019

- 1.47 MB