Separator Film Testing for Electric Vehicle Batteries

A separator is a membrane that separates a battery cell's anode from its cathode. Separator films are a critical part of lithium-ion batteries and other liquid electrolyte batteries. The polymers used for these films must be strong enough to withstand the winding operation during assembly as well as plating of lithium on the anode in an uneven manner due to extensive use. Issues with the selection of the cell separator materials can compromise battery integrity and increase the potential for internal short circuits, leading to thermal runaway, fire, and even explosions. Safer and stronger separator material more effectively prevents contact between the anode and cathode, while thinner material helps reduce the weight of each battery and improve energy density.

The main tests performed to evaluate the mechanical properties of separator film are tensile, puncture, and coefficient of friction tests. Tensile and coefficient of friction testing are critical for ensuring the separator film can withstand manufacturing of the battery, while puncture resistance is a crucial mechanical property used to assess and select the material with the best performance, while reducing the thickness, number of layers, and weight. UL 2591 (Component certification for lithium-ion battery cell separators) was specifically designed

to develop a comprehensive approach to cell separator testing in order to address safety

concerns associated with separators becoming progressively thinner and lighter due to industry trends.

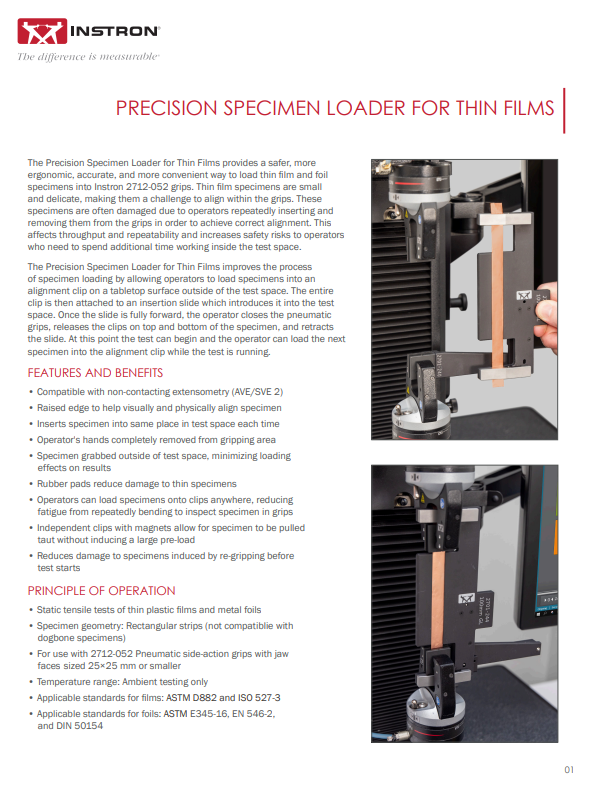

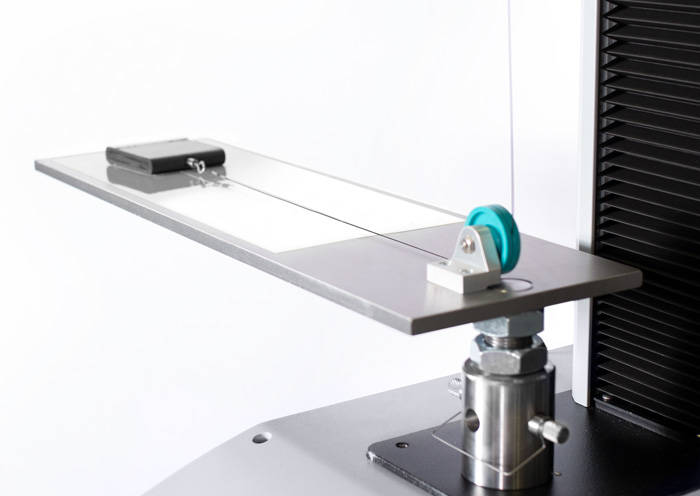

Tensile testing ensures that separator film can withstand all tensile forces applied during manufacturing and throughout the service life of the battery. There are several standards suitable for tensile testing polymer separators, including ASTM D882 and ISO 527-3. Ensuring proper specimen alignment, insertion, and grip operation are necessary for best repeatability and throughput, as well as to avoid possible damage to a specimen before testing. Instron offers a variety of solutions for tensile testing battery separator films, with both affordable and premium tiers of products designed to provide superior accuracy and throughput for labs requiring them. Testing these materials in accordance to ASTM D882 can be very beneficial for quality control checks as well as during R&D when trying to determine the optimal separator film solution. Additionally, as is the case for many other thin film materials, separator film is anisotropic and so is recommended to be tested in multiple different cutting/testing directions.

Puncture Test

Separator film must be strong enough to withstand punctures from dendrites that form with extensive battery use. This is critical for ensuring the safety and longevity of each cell throughout the lifespan of the battery. Ensuring proper specimen tautness and alignment of the upper probe are critical for this application. ASTM F1306 outlines the puncture testing of flexible barrier films to characterize the material response when a 3.2 mm diameter probe is driven into a clamped specimen. EN 14477 is another standard that characterizes the puncture resistance of thin film materials, however, it uses a smaller probe (0.8 mm) compared to ASTM F1306. High-speed puncture resistance testing to ASTM D3763 can be determined by use of Instron's 9450 Series drop tower.

Coefficient of Friction Test

Tight winding creates mechanical loads between the separator film and the electrode coating, and understanding the coefficient of friction can ensure that proper winding processes occur in production. It is common to use ISO 8295 and ASTM D1894-14 as guidance for this testing.

Automation

Automation systems from Instron introduce a new level of productivity for battery testing. As battery production volumes continue to increase, throughput and efficiency are critical to keep up with demand. Utilizing an automation system with the recommended equipment for each application can free up operators and maximize throughput, while maintaining optimal results.