ASTM D3039: Tensile Properties of Polymer Matrix Composite Materials

A Guide for Testing Polymer Matrix Reinforced Composites to ASTM D3039

Written By: Ian McEnteggart

Updated: November 18, 2025

ASTM D3039 is a widely used standard for determining the tensile properties of composite materials. More specifically, this standard applies to composites that consist of a polymer matrix reinforced by either continuous or discontinuous high modulus fibers.

Due to their high strength-to-weight ratio, these types of composites are commonly used for aerospace, automotive, and renewable energy applications.

This guide introduces the key elements of ASTM D3039 testing, including equipment, software, and samples needed.

What Does ASTM D3039 Measure?

ASTM D3039 testing involves applying a tensile force to a specimen (coupon) and measuring various properties. Testing is conducted on a universal testing machine (also called a tensile testing machine) and the standard incorporates both inch-pound and SI units.

Key measurements include:

- Ultimate tensile strength – Maximum stress applied (typically at break)

- Ultimate tensile strain – Strain at break

- Tensile modulus – Material stiffness

- Poisson’s ratio – Ratio of the change in transverse to longitudinal strain

- Transition strain – In cases where the material shows a yield behavior as indicated by a slope change in the stress-strain response, the transition strain is the strain value where the slope change occurs

- Failure mode – Broken specimens must be examined and their failure type, area, and location must be recorded

Is ASTM D3039 the Right Standard?

ASTM D3039 is one of the most basic tests for characterizing the tensile properties of composite materials. However, other standards exist to evaluate the many different mechanical properties of anisotropic and heterogeneous composite materials, including:

- ASTM D3410 and ASTM D6641 for compression testing

- ASTM D3518 for in-plane shear testing

The Composites Application Module in Instron’s Bluehill Universal software includes a pre-configured test method for ASTM D3039 and many other standards. View the full list of available method templates in Bluehill Universal.

Specimen Types

ASTM D3039 specimens are rectangular in shape with a constant cross-section.

The standard includes recommended specimen geometries for 0⁰ unidirectional, 90⁰ unidirectional, balanced and symmetric, and random-discontinuous material types.

ASTM D3039 can be used for both continuous and discontinuous fiber reinforcements, but the lay-up of the laminate specimen must be balanced and symmetric with respect to the test direction to ensure that the specimen does not twist or distort while under load.

Specimen Tabs

It is common practice in composites testing to use tabs to protect the specimen material from being damaged by the grips. ASTM D3039 does not require tabs, but it does recommend their use when testing unidirectional materials.

Tabs can either be bonded to the specimen or held in place by friction (e.g. emery cloth).

Specimen Measurement

Before testing, the specimen’s cross-sectional area must be measured. This is done by measuring the width and thickness at three places within the gauge section and averaging the measurements.

- When one or both surfaces are irregular, a micrometer with a ball interface is required to measure thickness.

- If both surfaces are flat, then a micrometer with a ball or flat interface can be used.

- Use a caliper or micrometer with a flat anvil to measure specimen width.

Best practice: To eliminate the chance of input errors and for improved efficiency, use an automatic specimen measurement device capable of transmitting measurements directly to the testing software.

The Automatic Specimen Measuring Device feature in Bluehill Universal allows operators to connect up to two devices (micrometers or calipers) simultaneously.

Materials Testing System

The testing for ASTM D3039 is performed on a universal testing machine.

- A 30 kN or 50 kN system may be sufficient for testing glass fiber composites.

- A 100 kN or 300 kN system is generally needed for testing carbon fiber composites.

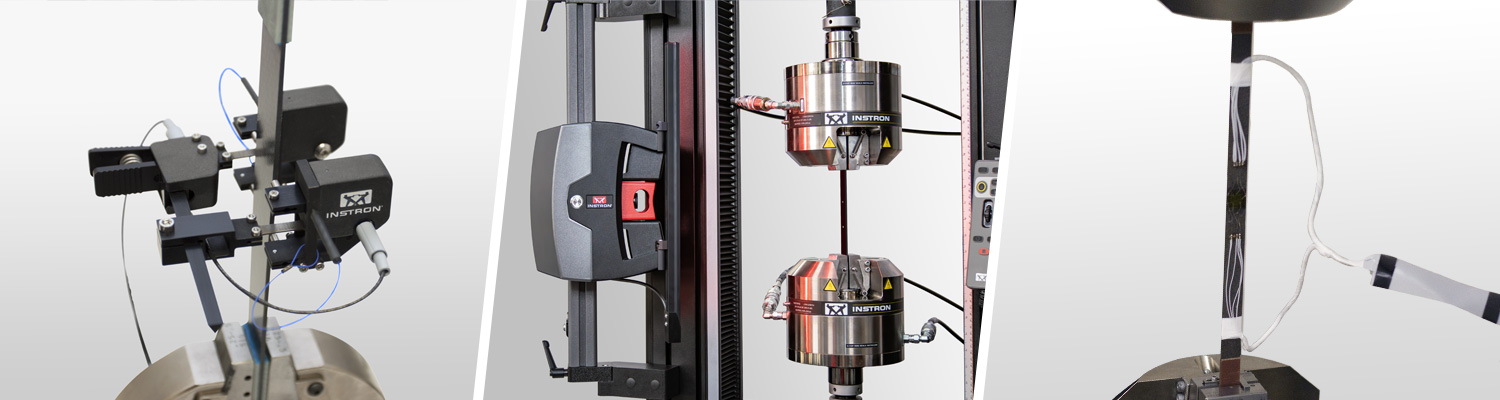

Grips and Specimen Alignment

The tensile grips used to hold composite specimens must provide sufficiently strong and even pressure to prevent the specimen from slipping during testing.

Recommended Grips

Both grip types provide a reliable clamping force and use a moving body design which minimizes the compressive forces when loading a specimen.

Optional specimen alignment devices can be installed on these grips to set the optimal alignment for more consistent results.

Recommended Jaw Faces

- Tabbed specimens: Serrated jaw faces

- Untabbed specimens: Flat jaw faces with a hard, high-friction coating (e.g. surfalloy, carbide)

Note: In some cases, emery cloth can be used with serrated faces to grip untabbed specimens.

Strain Measurement

Strain is measured using an extensometer or strain gauges.

Clip-On Extensometers (e.g. 2630 Series)

- Manually attached to the specimen at the start of each test

- May need to be removed before the specimen breaks if the failure is violent

- May not be suitable for measuring strain at failure

- Can be used in environmental chambers up to max temperature of 200°C

Non-Contacting Video Extensometers (e.g. AVE3 Advanced Video Extensometer)

- Camera measures deformation using markings on the specimen

- Cannot be damaged by the energy released at failure

- Can be used with an environmental chamber for non-ambient testing – mounts outside the chamber, eliminating the need to open and close the door during testing

Transverse Extensometers

If testing for Poisson’s ratio, a transverse extensometer is required to measure the change in width throughout the elastic region of the specimen.

A standalone transverse extensometer can be used to supplement a clip-on or video extensometer, or a biaxial device can be used to measure both axial and transverse strain simultaneously with a single device.

Strain Gauges

- Electrical resistance strain gauges are commonly used to measure strain at failure in composites.

- Typically consist of a thin metal foil grid that gets bonded to the specimen with an adhesive

- Can be used in environmental chambers – from cryogenic temperatures to over 200°C

- Requires conditioning electronics to generate a useful signal. Instron offers an easy-to-use adapter for the standard electronics in an Instron test machine.

While strain gauges can provide very accurate strain measurements, they are a costly consumable that requires skilled labor to install properly.

Non-Ambient Testing in Environmental Chambers

Composite materials often require testing under non-ambient conditions to characterize material performance under application temperatures.

Environmental chambers use forced air convection along with resistive heating elements to achieve high temperatures, and liquid nitrogen or carbon dioxide cooling to achieve low temperatures.

The Instron 3119-600 Series environmental chambers provide extensive temperature testing capabilities for evaluating material properties under non-ambient conditions. A full range of complementary grips, pull rods, and extensometers are available.

Final Notes

ASTM D3039 is essential for understanding the tensile behavior of polymer matrix fiber reinforced composites. While this guide provides a comprehensive overview, always consult the full ASTM D3039 standard for detailed procedures and compliance.

Frequently Asked Questions

| ASTM D3039 | ASTM D638 | |

|---|---|---|

| Materials | ASTM D3039 covers the determination of the in-plane tensile properties of polymer matrix composites reinforced by either continuous or discontinuous high-modulus fibers.

The properties of continuous fiber composite materials can be highly anisotropic, i.e. they depend strongly on direction. |

ASTM D638 covers the determination of the tensile properties of unreinforced and reinforced plastics. Composites reinforced with high modulus fibers shall be tested to ASTM D3039.

The types of plastic material tested using ASTM D638 are expected to be essentially isotropic, i.e. the properties are approximately the same in all directions. |

| Specimens | ASTM D3039 specimens are all flat and rectangular. This reduces the possibility of shear failures in the grips.

Bonded or friction tabs are recommended for some types of material, e.g. unidirectional to prevent the grip’s jaw faces from damaging the composite fibers and causing premature failure. The specimens are typically produced by cutting flat laminate sheets using a diamond saw. |

ASTM D638 specimens have a reduced width in the gauge section and wider widths in the gripping section.

The specimens are usually produced by injection molding. |

| Strain Measurement | ASTM D3039 specifies the use of either an extensometer calibrated to ASTM E83 Class B-1 or strain gauges complying with ASTM E251.

The failure strain of most composite materials is less than 5%, so these strain measurement devices do not require a large travel. |

ASTM D638 requires an extensometer calibrated to ASTM E83 Class B-2 for modulus and low-extension (<20%) measurements along with the use of crosshead displacement to determine “nominal strain” for high-extension measurements. |

| Calculations | ASTM D3039 includes calculations for:

|

ASTM D638 includes calculations for:

|