콘크리트 빔의 충격 성능

충격 3점 굽힘 설정을 한 콘크리트 빔에 대한 시험 수요가 높아지고 있습니다. 우리는 필요로 하는 최대 에너지에 따라 이 9450 과 9440을 시험에 추천합니다. 300mm 폭의 주문형 치구와 정밀 텁 인서트(tup insert)를 개발하였으며, DAS 와 Bluehill lMPACT 소프트웨어를 데이터 획득 용도로 사용하였습니다.

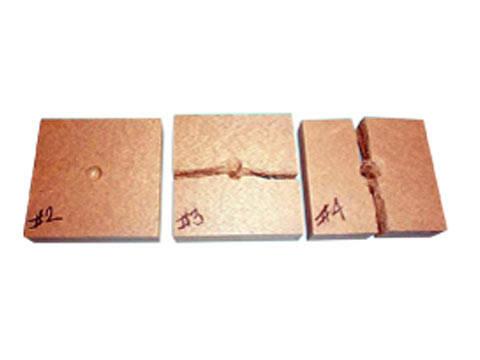

샘플은 400mm x 100mm x 100mm이며, 4.65m/s까지 시험됩니다. 속도는 필요로 한다면 더 높일 수 있습니다. 시험은 파괴 모드를 보여주며, 시험에서보다 훨씬 더 큰 에너지를 필요로 하는 더 큰 구조물을 시험하도록 설계되어 있습니다. 비교되는 결과의 종류는 흡수된 전체 에너지, 최대 하중, 파괴될 때까지의 에너지와 변형량입니다.

9300 시리즈는 고객이 그들의 재료가 충격을 받을 때 성능 특성을 알아내는데 도움을 주기에 적합합니다. 충격 시험을 통해 얻은 정보는 고객에게 데이터 기준치를 공급하여 그들이 실제 상황에서 그들의 혼합된 원재료가 어떻게 변하는지 알아내는데 쓰입니다. 다양한 온도에서의 충격 특성을 파악하기 위한 환경 챔버를 사용하거나 다른 종류의 시편 폭(span) 또는 다양한 충격 형태를 시뮬레이션 하기 위한 여러 치구들을 사용함으로써 더 폭넓은 시험을 할 수 있습니다.

9400 Series Drop Tower Brochure

Instron Drop Towers are used to develop, fine tune, and validate material models. Testing materials under real impact conditions is a crucial step prior of product design. Using the characterization data obtained with the Instron 9400, coupled with customer supplied high-speed video, you can have confidence in your results and deliver new materials to your customers faster. Our Drop Tower impact systems, fixtures, and tups are designed to meet a wide range of applications and testing standards including: ISO, ASTM, ANSI, Airbus, Boeing, BSI, DIN, EN, FDA, Ford, GM, JIS, NASA, GOST, and more.

- 제품소개

- 02/05/2020

- 763.1 KB

9400 Series Dashboard Brochure

Bluehill® Impact is built from the ground up for touch interaction. The Operator Dashboard features large touchpoints to make the user experience simpler and smarter. Easy-to-understand icons and workflows make it easy to train new or experienced users, simplify operator training, and allow you to start testing even faster than ever before

- 제품소개

- 08/01/2019

- 2.35 MB