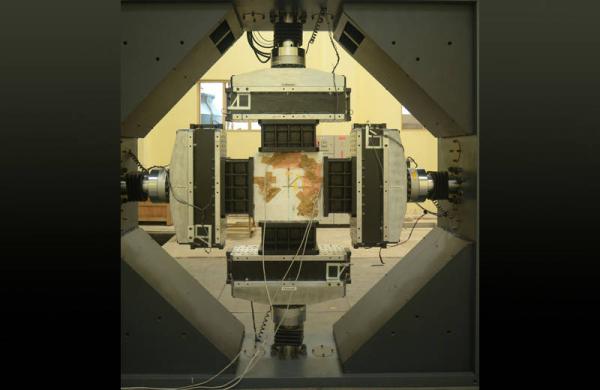

BI-7060 Biaxial Test System

BI-7060 The Biaxial cruciform specimen test systems feature high-stiffness; precision-aligned annular load frame with 4 four identical and independently controlled servo-actuators Using the advanced features of the controller to provide translation and deformation control of each axis, these systems are ideal for strength, fatigue and fracture testing of cruciform type test specimens with cracks or notches under a wide variety of synchronous biaxial load conditions with automatic specimen alignment to avoid shear loads.

Features

- Displacement up to +/-150mm.

- Self-reacting high stiffness biaxial load

- frame with integrated service manifold and hard

piping. - Wide range of grips and accessories.

- Fatigue rated actuators with hydrostatic bearings.

- High frame natural frequency.

- Encoder based displacement measurements.

- Energy efficient pumps.

- Optional heating pad for elevated temperature test

- Large specimen mounting area.

- Servo-electric options available.

- Horizontal and vertical options.

- Environment chamber and bio-bath options

- Suitable to test metals, alloys, composites including structural details

- State of art 3648 MIPS DSP, 2746M

- FLOPS DSP 24-bit analog data conversion, 32-bit data acquisition and 40-bit servo-loop calculations.

- Data acquisition rates up to 40kHz.

- User friendly application software with auto centering features.

- Optional DCPD arrangement to measure crack size.

Applications

- Aerospace materials testing.

- Aerospace design detail evaluation.

- Pressure vessel shell/skin response.

- Pressurized fuselage skin and launch vehicle shell

response. - Fatigue toughness and fracture mechanics.

- Bi-axial stress-strain response.

- Biological tissue growth studies.

- Bi-axial high strain rate test