EN 868-5 Verpackungsmaterialien für in der Endverpackung zu sterilisierende Medizinprodukte

EN 868-5 characterizes the seal strength of single-use sterilized medical packaging. This standard specifically focuses on packaging materials and systems for medical devices which need to be sterilized. The seal strength identifies the adhesion strength between the two materials of the packaging; typically, a coated paper backing, and a plastic film overlay. This standard is technically equivalent to ASTM F88 with minor differences in the specimen preparation and test procedure.

While packaging can span many industries, The seal strength of medical packaging is extremely important for two reasons – first to ensure that the packing can be opened easily by the medical professional, and second to ensure that the adhesive is strong enough to prevent any breaches of the packaging prior to their use. During shipping and storage the adhesive must remain viable to maintain sterilization: any breach in the packaging would desterilize the product potentially leading to life threatening infections for the patient.

EN 868-5 Test Setup

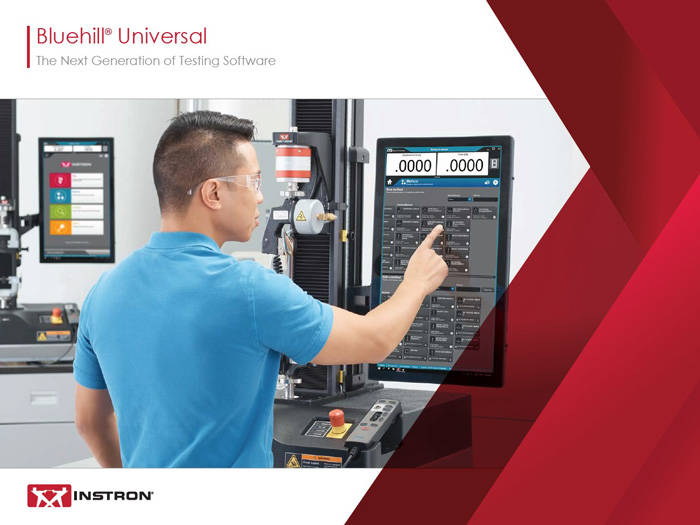

EN 868-5 can be performed on an Instron 3400 or 6800 Series single column universal testing system with a 500 N load cell.

| EN 868-5 Test Setup | |

|---|---|

3400 Series Universal Testing System |

|

Bluehill Universal Software |

|

2530 Series Load Cell |

|

2710-112 Screw Side Action Grips |

|

Grips

When testing an adhesive to a thick substrate, standard grips result in a misaligned specimen. Testing to EN 868-5 requires either advanced screw side action grips or pneumatic side action grips, both of which can be adjusted to offset to ensure that the specimen remains centered in the load string. Pneumatic grips provide an advanced solution by ensuring a repeatable gripping force to eliminate slippage specimen slippage. Both options can be fitted with specimen centering devices to ensure proper alignment for each test, and both employ a patented “quick-change” jaw face design which enables operators to easily change jaw faces to accommodate the needs of their materials. Rubber-coated grip faces should be used so as to avoid tearing the delicate specimen. Jaw faces are available in many different sizes and are easily interchangeable.

Tips and Tricks

The specimen width and test speed are different than ASTM F88, but produce statistically similar results when the data is normalized.