Sensors

Challenge

Durability testing requires a range of transducers that can provide critical feedback signals to the controller under dynamic loading conditions. As safety critical components, sensors need to be fatigue rated to survive the cyclic loads they experience during normal operation. Transducer calibration over the full measurement range needs to be accredited, repeatable and stable in order to guarantee the integrity of the test results. Test applications typically require special transducer designs to meet the demanding service loads and range of operational conditions.

Solution

Instron design and manufacture a wide range of transducers to meet the specific demands of test applications. Sensors are available for static and dynamic force, torque, displacement, pressure, strain, acceleration and temperature measurement. All Instron transducers are suitable for use as control feedback sensors or for data acquisition of test results. Instron has accredited calibration laboratories and is able to provide on-site traceable calibration of force transducers to international standards.

Load Cells

Instron precision load cells are used to determine static and dynamic tensile and compressive forces, which are usually built up by a load unit and transferred to a test specimen. Together with measuring amplifiers, they form a highly accurate measuring system for the material and component testing as well as for vibration resistance tests in the force change range. On account of the different sizes, they can be selected correspondingly to the respective load units.

Torque transducer

The torque transducer PM-T allows a torque measurement on Hydropuls® rotary cylinders in conjunction with the measuring amplifier. In the torque transducer PM-T, a mechanical torque is converted into an electrical resistance change. The measuring amplifier converts this resistance change into an electrical voltage.

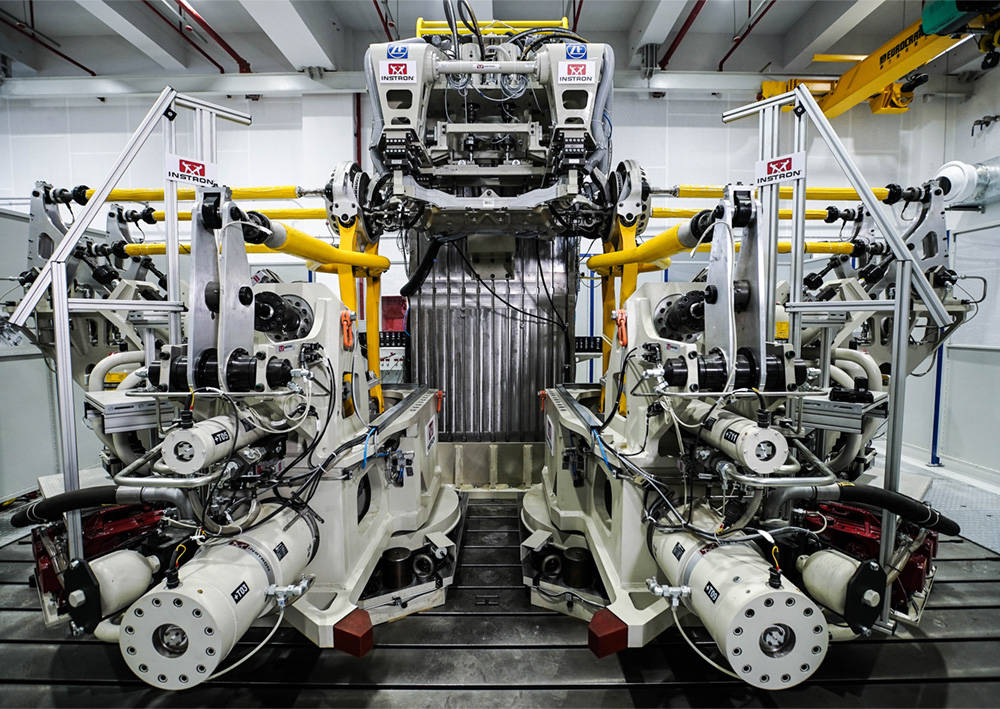

Axle Test System

Axle test rigs are used to reproduce different loads applied to the axle elements when a vehicle is traveling over a variety of road surfaces. Instron can provide models for testing of car, van, truck and bus axles with 6 degree-of-freedom.

더 알아보기Component Test Systems

Instrons component testing systems are characterized by the highest quality and reliability, ensuring the highest productivity in daily use.

더 알아보기Multi-Axis Shaking Table (MAST)

Multi-axis simulation (MAST) tables are designed for testing of a variety of different specimens in six degrees of freedom. These include components and subassemblies exposed to vibratory loads during vehicle operation; from seats, dashboards and interior equipment components to engine mounts, and cooling modules.

더 알아보기Road Simulator

HYDROPULS® road simulators are a versatile and cost efficient solution for testing load inputs through the tires. They are used to perform durability tests, as well as acoustic and vibration analyses in testing and development (BSR, NVH) on complete vehicles, subsystems and power train assemblies.

더 알아보기Full Vehicle Test System

Instron offers comprehensive solutions with and without vehicle restraint, with long- or short-stroke introduction of lateral forces as well as the optional environmental simulation with regard to temperature humidity and sun loading.

더 알아보기Dynamic Torsion Test System

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed.

더 알아보기Shock Absorber Test Systems

Instron's MSP test system is the ideal tool for reliable, fast and realistic tuning of vehicle chassis designs and development of shock absorber systems.

더 알아보기