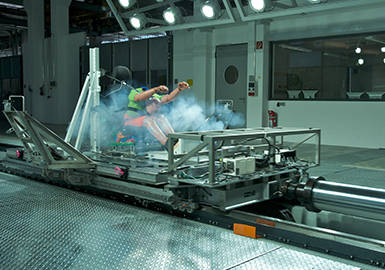

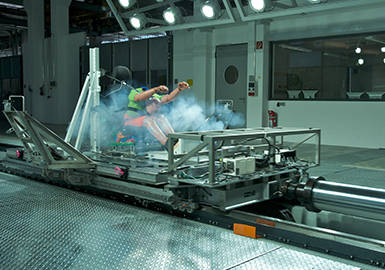

Our Solution

Instron's CSAadvanced acceleration sled systems permit the execution of a variety of testing procedures, including dynamic seat tests, frontal crash simulation with synchronized, actively controlled vehicle pitch movement, or testing of cargo restraint systems. With short charging cycles and a high degree of automation, Instron acceleration sled systems can be ready for another shot within 10 minutes. Intelligent solutions for rapid changeover between test setups (such as a 2-piece sled, or pallet systems for a 1-piece sled) enable more than 2000 test cycles to be conducted per year. In addition, the CrashSim-Office software enables crash pulses to be imported and edited offline, outside the test laboratory, including the generation of the associated drive signal for the test and without the need to use the crash simulation rig for validation of the feasibility of a new test pulse. All these features make Instron CSAadvanced acceleration sled systems a highly efficient and powerful development tool.