Proportional Limit

The proportional limit is the point on a stress-strain curve where the linear, elastic deformation region transitions into a non-linear, plastic deformation region. In other words, the proportional limit determines the greatest stress that is directly proportional to strain. The transition point can be calculated by a specified percent change in slope. Because the proportional limit is not required by many test standards, it is often used for educational purposes rather than in practice by the materials testing industry.

How is Proportional Limit Different from Elastic Limit?

The elastic limit is the greatest stress that can be applied to a material without causing plastic (permanent) deformation. For many materials the elastic limit is equivalent or nearly equivalent to the proportional limit. For other materials, such as elastomers, the stress-strain relationship is non-linear and the material will still be within its elastic region long after it has passed through its proportional limit. The elastic limit is essentially a theoretical value that is difficult to determine using a universal testing machine, and for this reason is used mainly for educational purposes rather than in practice by the materials testing industry.

How is Proportional Limit Different from Yield Strength?

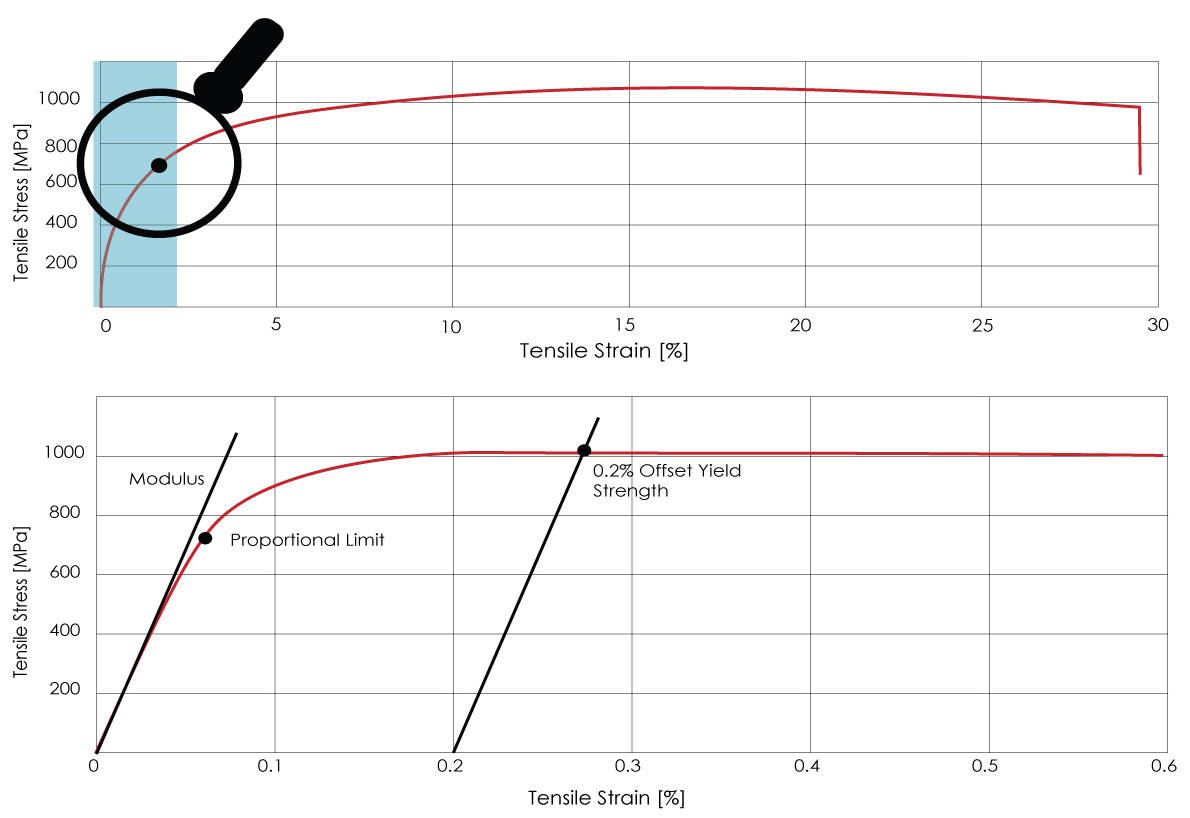

Similar to the elastic limit, the yield strength of a material can also occur beyond the material’s proportional limit. Unlike the elastic limit, the yield strength on a stress-strain curve has been defined by ASTM and ISO test standards. Depending on the material’s stress-strain behavior at yield, a preferred yield calculation is specified by the chosen standard. For instance, metals test standards (ASTM E8 or ISO 6892) have standardized a 0.2% offset yield, which allows the metals industry to objectively evaluate different metals against each other. The stress-strain curve below displays the difference between the proportional limit (4% change in slope) and the 0.2% offset yield point in a metals test.

Bluehill Universal 型錄

Bluehill Universal 是 Instron 的先進材料測試軟體,專為直覺式觸控互動和精簡工作流程而設計。它提供預載測試方法、快速設定的 QuickTest、強化的資料匯出功能,以及可直接與服務部門溝通的 Instron Connect。Bluehill 2 和 Bluehill 3 的使用者可輕鬆升級至最新版本,以提升效能和可用性。

6800 系列 – 万能材料试验系统

Instron 的6800 系列万能材料试验系统提供出色的精度及可靠性。 6800 系列基于正在申请专利的操作员保护架构,具有全新的智能气动控制装置和碰撞保护功能,使材料测试比以往任何时候都更简单、更智能、更安全。