ASTM D790 塑膠彎曲測試的權威指南

How to Perform a Flexural Test on Unreinforced and Reinforced Plastics According to ASTM D790

Written By: Kayla Thackeray

Updated: January 14, 2026

ASTM D790 is a standardized test method used to determine the flexural (bending) properties of reinforced and unreinforced plastics, high-modulus composites, and electrical insulation materials.

This guide provides an overview of key elements involved in an ASTM D790 flexure test, including testing equipment, software, and specimen requirements. However, it is not a substitute for the official ASTM D790 standard. Anyone planning to perform this test should consult the full standard for complete instructions and compliance requirements.

Is ASTM D790 the Right Standard for You?

ASTM D790 is one of several standards used to measure the flexural properties of plastics.

It is not intended for tensile testing. If you need to determine the tensile properties of plastic materials, refer to ASTM D638.

Additionally, ASTM D790 does not apply to materials that exceed 5% strain without breaking or yielding. For those materials, a 4-point bend test in accordance with ASTM D6272 may be more appropriate.

Find insights into other applications in our plastics testing knowledge base.

Key Differences Between ASTM D790 and ISO 178

While ASTM D790 and ISO 178 both measure flexural properties, there are several important distinctions:

Modulus Calculation

ISO 178 requires the use of either a deflectometer or compliance correction to determine modulus. In ASTM D790, this is only a recommendation — modulus can be calculated by crosshead displacement alone.

Specimen Dimensions and Test Speed

Preferred specimen sizes differ between the standards, which impacts test speed.

- ASTM D790: Preferred specimen depth = 3.2 mm

- ISO 178: Preferred specimen depth = 4 mm

Because test speed depends on specimen depth, speeds may vary between the two standards.

Test Speed Options

ASTM D790 only allows one test speed, whereas ISO 178 permits a second, faster test speed after modulus is measured.

What Does ASTM D790 Measure?

ASTM D790 measures the flexural properties of a material while under a bending strain or deflection. This test is conducted on a universal testing system using a three-point bend fixture at a rate proportional to the depth of the specimen.

ASTM D790 testing is used to determine the following mechanical properties:

- Tangent modulus: Also known as flexural modulus, this is the slope of the initial linear portion of the load deflection curve and is a measurement of the material's stiffness.

- Secant modulus: The slope between the origin and a predefined point on the load deflection curve.

- Chord modulus: The slope between two predefined points on the load deflection curve.

- Flexural strength: The maximum flexural stress obtained during a bend test.

- Flexural stress at break: The flexural stress at which a specimen breaks during a bend test. For some materials, the specimen breaks before a yield point, in which case the flexural strength equals the flexural stress at break.

Test Speeds

The required test speed for ASTM D790 is expressed as a function of specimen support span, specimen depth, and strain rate — using the following equation to determine the crosshead rate.

- R = rate of crosshead motion (mm/min)

- L = support span (mm)

- d = depth of specimen (mm)

- Z = rate of straining of the outer fiber (mm/mm/min)

Rate of straining of the outer fiber (Z):

- Procedure A: 0.01 mm/mm/min

- Procedure B: 0.1 mm/mm/min

Procedure A is preferred, but if a break does not occur in the material before 0.05 mm/mm, then Procedure B is used.

Testing Tip: Bluehill® Universal's Expression Builder feature allows users to input test speed as a function instead of as a static number. After the test operator enters the specimen measurements, the software will automatically modify the test speed according to the equation.

Specimens Dimensions and Preparation

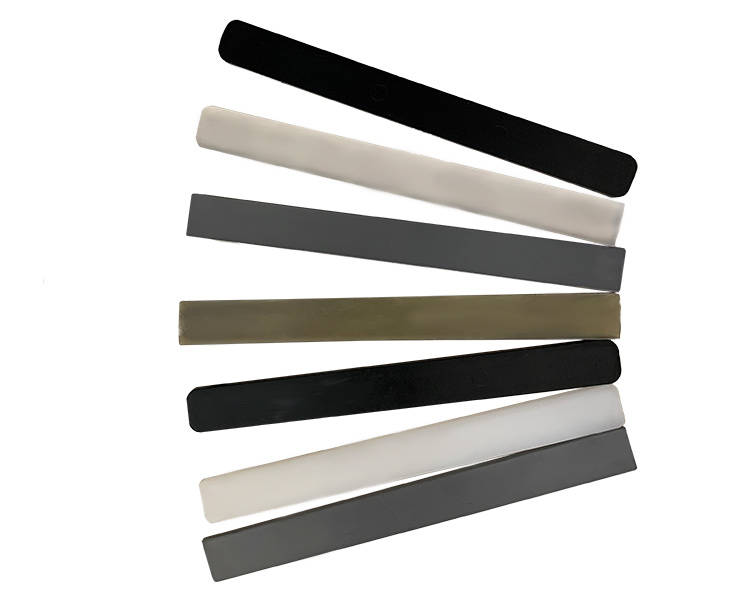

ASTM D790 specimens are rectangular and can be molded, extruded, or cut from plates or sheets. The dimensions depend on the material's thickness, which the standard defines as the specimen depth.

- Sheet materials < 1.6 mm thick: Dimensions: 50.8 mm x 12.7 mm; support span = 25.4 mm

- Sheet materials 1.6 mm - 3.2 mm thick: Width = 12.7 mm; support span = thickness x 16

- Sheet materials > 3.2 mm thick: Width and span proportional to thickness

- Electrical insulating materials: Dimensions vary based on nominal thickness

- Molded materials: Typically 3.2 mm thick, 12.7 mm wide, and 127 mm long; support span = thickness x 16

For high-strength reinforced composites, follow the standard's dimension guidelines to ensure failure occurs in the outer fibers of the specimen.

Important: When testing composites and other anisotropic materials, specimens should be cut so that the strongest fiber direction is tested. Care should be taken to ensure that failure occurs only due to forces accrued during bending.

Specimen Measurement Requirements

Specimens must be measured using a micrometer that complies with ASTM D5947. For accuracy, take three measurements of both width and thickness, then report the average value.

Testing Tip: The Automatic Specimen Measuring Device (ASMD) feature in Bluehill Universal streamlines this process. It supports up to two micrometers or other measurement devices connected directly to your computer. This allows you to input the mean measurement automatically, reducing manual data entry errors and improving overall efficiency.

Test System

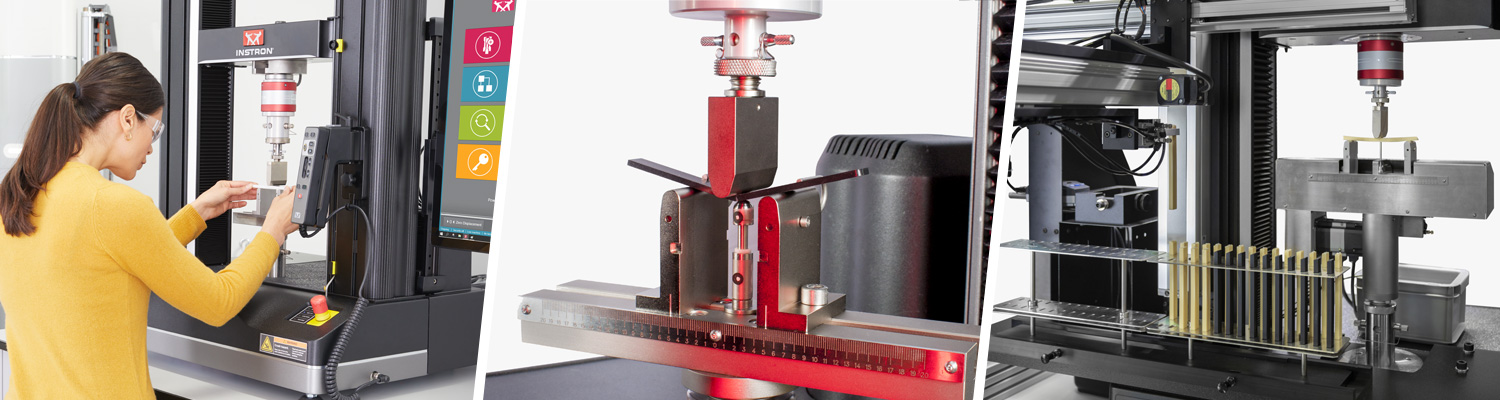

ASTM D790 testing can be performed on either a tabletop or floor model universal testing machine equipped with a variety of accessories to optimize your testing process. Because every laboratory has unique requirements, multiple system configurations are available.

The example basic configuration below features a 3400 Series universal testing system with a 3-point bend fixture and no extensometer. In this setup, strain is measured by crosshead displacement, which qualifies as Type 1 testing.

Note: 3400 Series systems can be paired with an extensometer for Type 2 testing, if needed.

Whenever strain is measured via crosshead displacement, compliance correction is recommended to improve accuracy - though it is not mandatory.

Advanced Testing System Options

The 6800 Series universal test system is a more advanced and efficient option for users desiring increased repeatability and higher throughput. Though this system can also be used for Type 1 testing, it is most commonly used for Type 2 testing, which relies on an extensometer and deflectometer in order to provide a more accurate reporting of strain.

Strain Measurement in ASTM D790 Testing

ASTM D790 allows strain to be measured in two ways:

- Type 1 Testing: Strain is calculated from crosshead displacement.

- Type 2 Testing: Strain is measured using an extensometer.

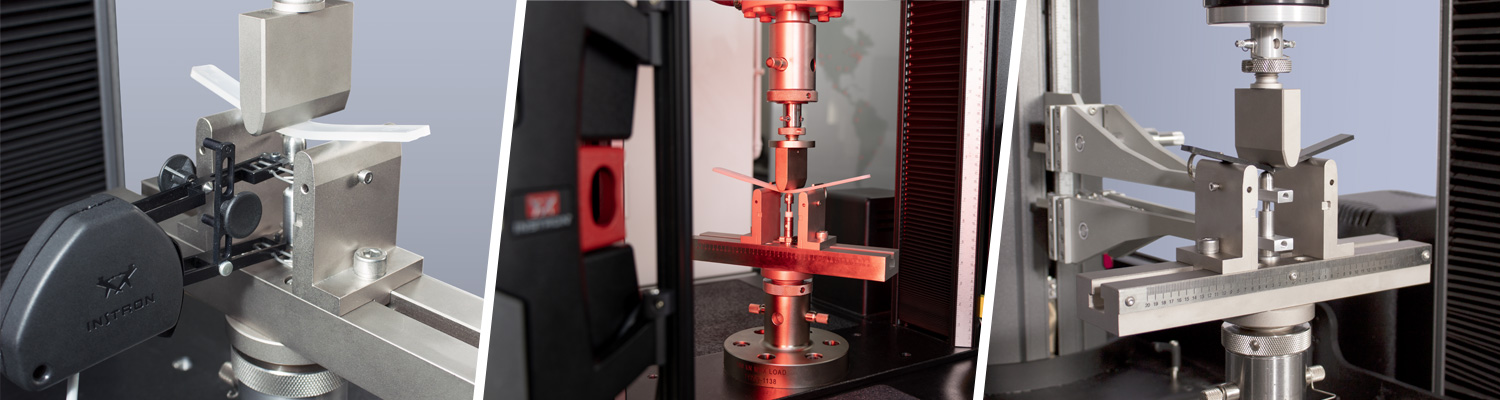

For Type 2 testing, you'll need one of the following extensometer options:

- Non-Contacting Video Extensometer - Measures strain without physically contacting the specimen or entering the test space. See Instron's AVE3 Advanced Video Extensometer.

- Automatic-Contacting Extensometer - Automatically attaches to a defined gauge length and can detach before failure, improving throughput and consistency. See Instron's AutoX750 Automatic Contacting Extensometer.

- Clip-On Extensometer - Fixed gauge lengths and travel capabilities that vary by device; requires manual attachment to the specimen. See Instron's Axial Clip-On Extensometers.

Important: Each extensometer listed above must be used with a deflectometer (catalog no. 2810-403) for accurate strain measurement.

Bend Fixture

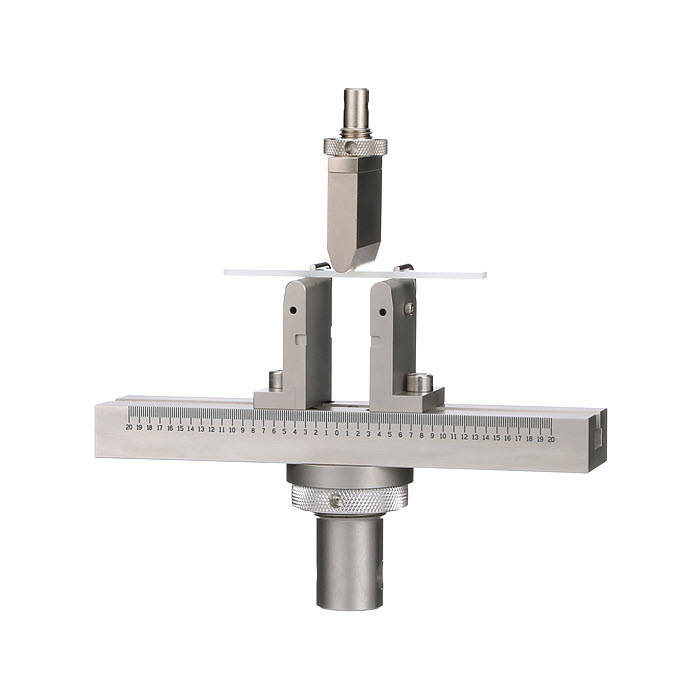

A three-point bend fixture is used for ASTM D790. This fixture consists of a loading nose attached to the moving crosshead and a fixed member with two specimen supports, or anvils, which can be adjusted to fit the distance of the specimens' support span.

The surface of the anvils and loading nose should be cylindrical and have a radii of 5 mm unless otherwise specified, and the length of the cylindrical member should be longer than the width of the specimen.

Instron’s 5 kN three-point bend fixture includes several key features to improve test accuracy:

- Graduated length units on the support beam for accurate positioning of the anvils and easy centering of the deflectometer when using strain devices.

- Alignment arms that can be adjusted to fit the width of the specimen.

Inconsistent specimen alignment can cause major variations in results and proper care must be taken to ensure that specimens are aligned consistently for each test.

Enhancing Throughput

For labs looking to increase their throughput, several modifications to the system setup can be made. Because ASTM D790 testing can be time consuming, Multi-Station 6800 Series testing machines are a popular choice for labs with high throughput needs. Fully automated test systems are also available, and are designed to incorporate specimen measurement, specimen loading, testing, strain measurement, and specimen removal. These systems can run for hours without requiring any operator interaction and help reduce variability due to human error.

Recent Changes to ASTM D790

The latest version of ASTM D790 was released in 2017. It differs from the previous version, 2015E2, in several ways:

- The verification requirement for Type 1 testing (crosshead displacement) was changed from a Class D system to a Class B system per ASTM E2309.

- The standard for Type 2 apparatus (deflectometer and extensometer) was changed from Class B to Class B-2.

- Note 10 and Appendix XI were added to the standard to explain what compliance correction is and how to apply it.