Non-Contacting Strain Measurement Techniques in Fatigue Testing of Polymer Matrix Composites

Advances in Extensometry

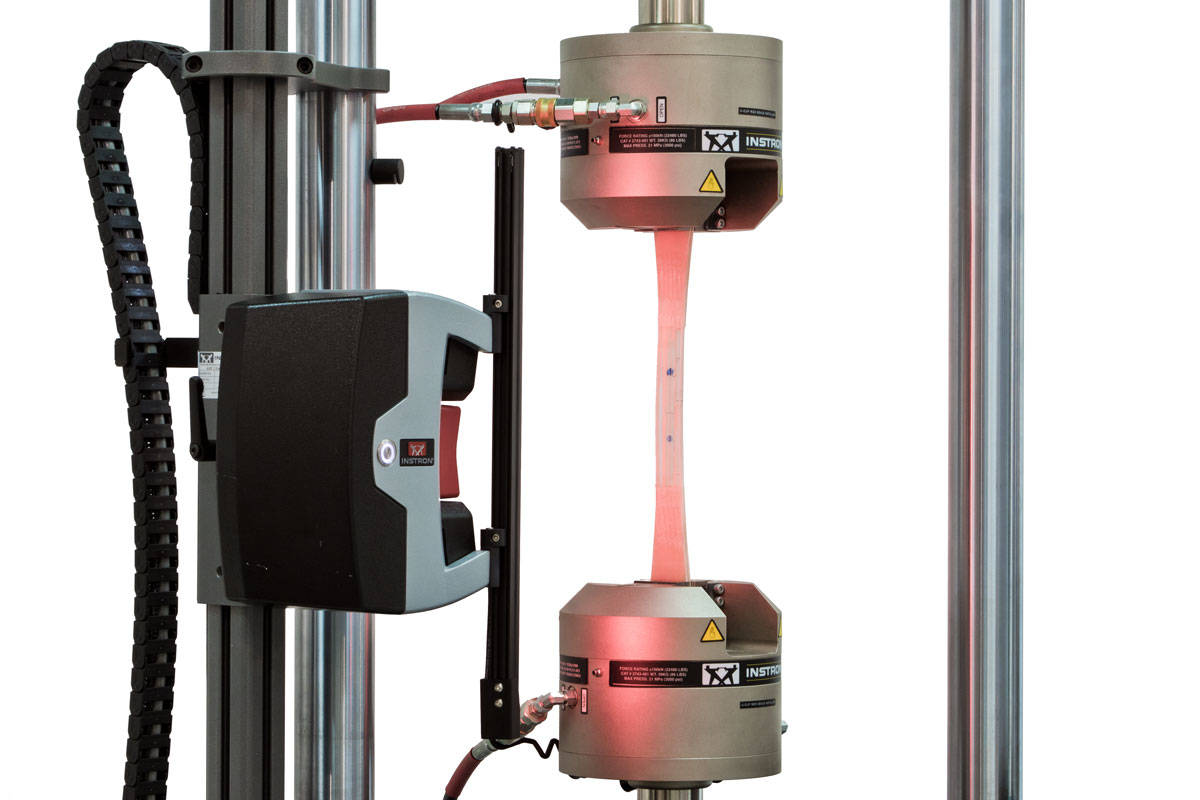

Things have come a long way since the original extensometer by J. A. Ewing (c.1890) which was screwed onto the specimen and manually read from a Vernier scale; now we have the ability to continuously and automatically measure strain without touching the specimen, but achieving better than micron resolution at up to 0.5m/s!

The latest video extensometer is capable of providing live strain measurement with only a few milliseconds delay, meaning that it can be used for highly dynamic tests, including direct strain control on the specimen.

Strain Measurement & Control for Fatigue

Using the latest non-contact strain measurement provides new potential for fatigue testing of composite materials, by making continuous measurements of global strains throughout every cycle. These can include:

- tracking strain without specimen damage

- measuring transverse strain dynamically

- active control of test waveform by gauge length strain

Any or all of these capabilities can be used to provide more insightful data and more repeatable tests – key challenges for generating useful studies in composites fatigue.

Strain Rate Effects

It is widely accepted that strain rate affects the behaviour of all materials, but that polymer matrix composites tend to be especially sensitive.

Taking the example of a carbon fibre reinforced polyamide compound for injection moulding, video extensometry allows observation of the changes in stress-strain curve, which would be challenging to measure with a clip-on extensometer at anything above the slowest speed.

Clearly quasi-static test data is a poor point of reference for most practical fatigue tests, where even small stress levels and moderate frequencies the strain rate can be greater than 5%/s.

This article is a summary of a paper published by Dr. Peter Bailey and Maeve Higham.

Read the full paper provided by PROSTR (Procedia Structural Integrity).