血栓过滤器径向力评估

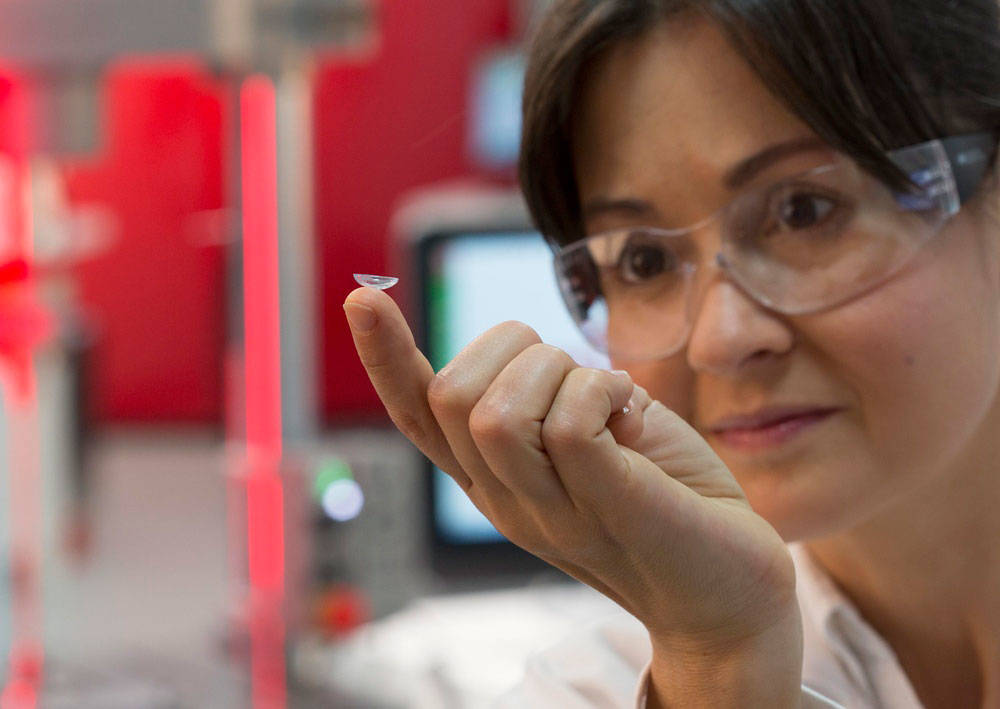

색전 필터(Embolic filters )는 스텐트(stent)와 같은 의료기구의 사용에 따른 파편을 걸러주기 위한 다양한 중재적 시술(interventional procedures)에 사용됩니다. 스텐트는 플라크(plaque)에 의해 막힌 동맥의 통로를 열어 주는데 사용됩니다. 스텐트의 위치를 잡을 때에 떨어진 플라크(또는 색전 물질)들이 잠재적으로 심장마비, 뇌졸중, 신장 손상 또는 사망에까지 이르게 할 수 있습니다. 이 색전 필터는 성공적인 시술을 위한 매우 중요한 부분입니다.

이 필터의 적합한 사용을 위한 매우 중요한 요소 중의 하나는 동맥 벽면에 전달되는 반지름 방향의 힘입니다. 특히 필터가 장기간 가해주는 장기적인 반지름 방향의 힘은 그 기구들이 제자리에 남아있도록 도와 줍니다. 이렇게 잘 맞아야 모든 물질들이 동맥의 통로를 따라 나가기 전에 잡아낼 수 있습니다.

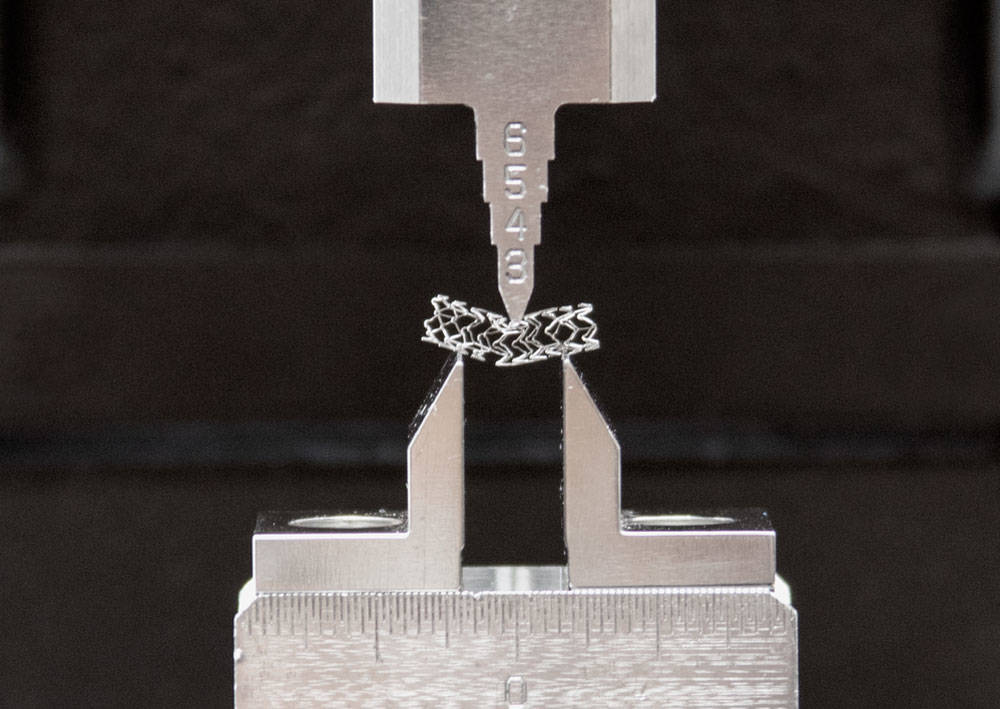

Instron® RX550 시스템은 색전 필터의 작은 반지름 방향 확장력을 충실히 측정합니다. 이 치구의 독특한 분할식 디자인은 마찰력이 낮아서 방사형 시험에서 얻은 데이터들이 깨끗한 결과를 나타내도록 해 줍니다. 이 방사형 치구는 기계식 만능재료시험기에 장착되며 체온의 정확한 시뮬레이션을 위하여 액체조(fluid bath)에도 장착할 수 있습니다. 또한 이 장비는 전개하는 동안의 인열 특성을 평가하기 위한 인장 시험 능력도 갖추고 있습니다.

Bluehill® Software 는 시험을 진행하기 위한 인터페이스를 제공하며 반지름 방향 강도를 측정하고 관리기관에 제출하기 위한 표준 보고서를 작성해 줄 수 있습니다.

3400 시리즈 – 경제적인 테스트 솔루션

인장, 압축, 굽힘 및 기타 재료 특성 테스트를 위한 Instron 3400 시리즈 범용 테스트 시스템.

- 제품소개

- 06/27/2022

- 2.49 MB

6800 시리즈 프리미어 시험기 브로셔

Instron 6800 시리즈 만능 시험기는 최고의 정확도와 신뢰성을 제공합니다. 6800 시리즈는 완전히 새로운 Smart-Close Air Kit 및 Collision Mitigation 기능이 있는 특허 출원 중인 Operator Protect 시스템 아키텍처를 기반으로 하며, 그 어느 때보다 간편하고 스마트하며 안전한 소재 시험을 가능하게 합니다.

- 제품소개

- 02/10/2020

- 3.56 MB