Textiles Testing

In the automotive sector, textiles must be aesthetically pleasing but also be durable to survive years of abuse. Automobile owners will see the interior of the vehicle every time they enter, so the importance of aesthetics cannot be understated. The automotive market is incredibly competitive, so any advances in the material technology of these textiles can provide a substantial advantage.

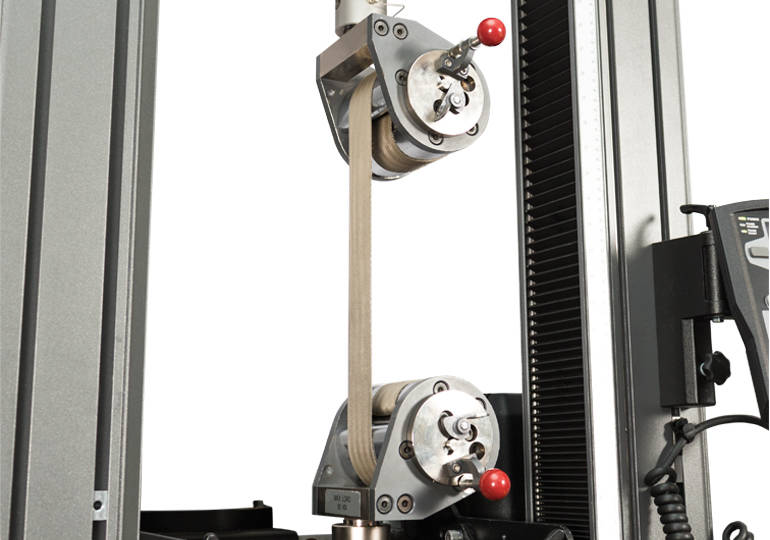

Textile Tensile Testing

Textile Pendulum Impact Testing

Learn more about our automotive solutions