Plastic Welds Tensile Testing

Plastic Welds Tensile Testing

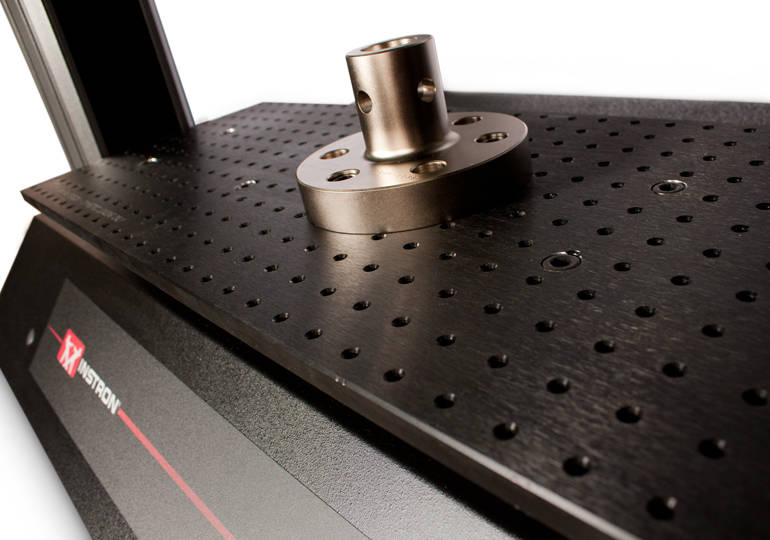

Specimen Gripping

As more and more components of cars are made using plastic, testing must be done to ensure that different plastic components will stay bonded together. From dashboards to gas caps, polymeric materials ranging from nylon to polypropylene can be found throughout vehicles. Plastic welding techniques such as vibration and laser welding are used to join different plastic components, in addition to traditional adhesive methods. To ensure that the bonds are sufficiently strong, tensile testing can be performed both during product development and quality control.