RETROFITS DO SISTEMA DAS SÉRIES 3400 E 6800

Atualize e modernize seu sistema de ensaios universal legado

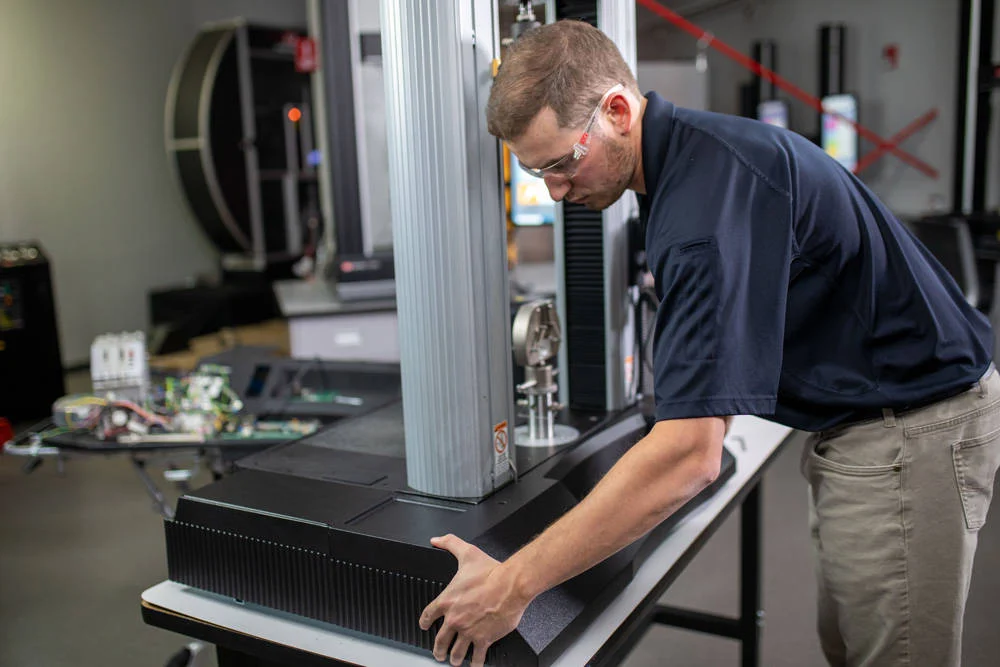

Os retrofits do sistema das séries 3400 e 6800 permitem que as máquinas de ensaios universais Instron legadas sejam atualizadas com eletrônica de controle e software modernos, estendendo a vida útil do seu sistema de ensaios e atenuando o risco de tempo de inatividade inesperado. Os sistemas modernizados também ganham acesso aos recursos de ensaio mais recentes, projetados para melhorar a eficiência, a ergonomia e a segurança do operador, bem como recursos expandidos para aproveitar os acessórios mais recentes.

PREVENÇÃO DE TEMPO DE INATIVIDADE

Para evitar tempo de inatividade não planejado e garantir a longevidade contínua da sua máquina, os retrofits do sistema da Instron fornecem uma revisão abrangente da sua máquina e substituem muitos componentes em risco. Esta atualização rejuvenesce seu sistema e pode estender sua vida útil por anos.

SUPORTE E CONFIABILIDADE

Muitos componentes legados na máquina existente são substituídos por hardware atual e moderno, garantindo que os componentes de substituição estejam imediatamente disponíveis caso haja necessidade de serviço. Os itens que são substituídos serão restaurados para a Fase 1 do Ciclo de Vida, garantindo tempo de inatividade mínimo caso uma dessas peças mais críticas da máquina falhe, pois esses itens são totalmente reparáveis e estão em produção atual da Instron.

DESEMPENHO AVANÇADO

Aproveite o que há de mais moderno em tecnologia de ensaio, recursos e software Bluehill® Universal projetado para otimizar sua operação e melhorar a segurança do operador. Além de preparar seu laboratório para o futuro, a atualização é totalmente compatível com a maioria dos dispositivos de carga e deformação legados, permitindo que você continue usando seus acessórios existentes.

ENSAIOS MAIS SIMPLES E SEGUROS

Aproveite a arquitetura de segurança mais recente sem sacrificar o rendimento

Proteção do Operador

Com os Retrofits das Séries 3400 e 6800, você obtém acesso à arquitetura de Proteção do Operador com patente pendente da Instron, um fluxo de trabalho inteligente que mantém equipamentos e operadores mais seguros, controlando o status do sistema desde a configuração até a conclusão do ensaio.

Orientação de segurança integrada

O Bluehill Universal fornece aos operadores indicações visuais claras indicando o status do sistema em todos os momentos. Isso torna mais fácil para os usuários saberem quando o sistema está em um modo de configuração seguro e fornece lembretes claros para sair do espaço de ensaio assim que os limites de segurança forem removidos.

Kit de ar com fechamento inteligente

Ao carregar corpos de prova em garras pneumáticas, o Smart-Close Air Kit usa uma pressão de garra mais baixa e velocidade de fechamento restrita, reduzindo os riscos de pinçamento dos dedos. Em seguida, aumenta para a configuração de pressão mais alta antes do início do ensaio.

Mitigação de Colisão

Durante a fase de configuração do ensaio, a Mitigação de Colisão reduz o risco de danos às células de carga, garras, acessórios, corpos de prova delicados e outros equipamentos, interrompendo a travessa se a força for detectada na subida ou durante um movimento.

Posicionamento automático

O Posicionamento Automático salva a separação correta do acessório ou a localização inicial para cada método de ensaio, garantindo que todos os operadores executem cada ensaio exatamente da mesma forma em todos os turnos todos os dias. Este recurso está disponível apenas nos Retrofits do Sistema da Série 6800.

DESEMPENHO AVANÇADO

Aproveite o que há de mais moderno em tecnologia de ensaio, recursos e software Bluehill® Universal projetado para otimizar sua operação e melhorar a segurança do operador. Além de preparar seu laboratório para o futuro, a atualização é totalmente compatível com a maioria dos dispositivos de carga e deformação legados, permitindo que você continue usando seus acessórios existentes.

EXPANDA SUAS CAPACIDADES DE ENSAIO

A modernização do seu sistema de ensaio legado permite a integração perfeita com acessórios modernos, abrindo as portas para novas capacidades de ensaio. Seu sistema modernizado será compatível com todos os acessórios de ensaio mais recentes da Instron, incluindo extensometria avançada e tecnologia de célula de carga para ainda maior precisão e exatidão.

ENSAIOS MAIS SIMPLES E SEGUROS

Hardware Atualizado e Novos Recursos

Retrofits do Sistema de Ensaios Universal das Séries 3400 e 6800

| Retrofits da Série 3400 | Retrofits da Série 6800 | |

|---|---|---|

| Sistemas Legados Elegíveis | Séries 3360, 3380 Modelos: 3365, 3366, 3367, 3369 3382, 3382A, 3384, 3385H |

4460, 4480, 5560, 5560A, 5580, Séries 5860, 5880, 5960, 5980 Modelos: 4464, 4465, 4466, 4467, 4469 4481, 4482, 4484, 4485 5564, 5565, 5566, 5567, 5569 5565A, 5566A, 5567A, 5569A 5581, 5582, 5584, 5585, 5585H 5864*, 5865*, 5866*, 5867*, 5869* 5881*, 5882*, 5884*, 5885, 5885H* 5965, 5966, 5967, 5969 5982, 5984, 5985 * As estruturas 586X e 588X modernizadas são convertidas em testadores estáticos |

| Painel do Operador Integrado da Série 3400 | ✔ | |

| Handset Ergonômico Removível da Série 6800 | ✔ | |

| Nova Eletrônica de Controle | ✔ | ✔ |

| Gabinete Eletrônico Robusto de Chapa Metálica | ✔ | ✔ |

| Motor CA sem Escova e Livre de Manutenção | ✔ | ✔ |

| Sensor de Velocidade | ✔ | ✔ |

| Amplificador de Potência | ✔ | ✔ |

| Correia de Acionamento | ✔ | ✔ |

| Botão de Parada de Emergência | ✔ | ✔ |

| Painel Indicador | ✔ | ✔ |

| Tampa Frontal do Sistema Aplicável apenas a retrofits de modelos de mesa. | ✔ | ✔ |

| Codificador Absoluto | ✔ | |

| Bateria de Posição Absoluta | ✔ | |

| Proteção do Operador | ✔ | ✔ |

| Orientação de Segurança | ✔ | ✔ |

| Mitigação de Colisão | ✔ | ✔ |

| Smart-Close Air Kit (Complemento Opcional) | ✔ | ✔ |

| Posicionamento Automático | ✔ | |

| Adaptadores de Célula de Carga Drop-Through Opcionais O adaptador de célula de carga drop-through permite que as células de carga da Série 2580 sejam usadas em uma estrutura modernizada, permitindo que você aproveite os recursos de desempenho avançado no software Bluehill Universal. Isso inclui a capacidade de medir forças até 1/1000 da capacidade nominal da célula de carga e dá à estrutura modernizada acesso total ao recurso de Mitigação de Colisão da Instron. | ✔ |

Notas Adicionais:

1. Os modelos não listados podem ser atualizados mediante solicitação. Entre em contato conosco para obter suporte.

2. A velocidade do sistema, a conformidade e as especificações gerais de operação são limitadas pelo sistema que está sendo atualizado e pelo equipamento de carga e deformação utilizado.

SOLUÇÕES DE ENGENHARIA

Não vê uma atualização de sistema que atenda às suas necessidades?

Nosso Grupo de Soluções de Engenharia e Equipe de Aplicações estão aqui para entender seus desafios exclusivos e trabalhar com você para criar uma solução que seja adaptada ao seu sistema de ensaio. Nossas soluções variam desde atualizações de sistema para máquinas em ambientes de ensaio agressivos até atualizações para sistemas de concorrentes.