INDUSTRIAL SERIES

High-Capacity Universal Testing Systems for Tensile, Compression, and Flexure Testing

The Industrial Series is comprised of high-capacity, hydraulic testing systems for tension, compression, and flexural applications. Ranging from 600 kN (135,000 lbf) to 2,000 kN (450,000 lbf), standard models feature large diameter columns and rugged components for superior frame stiffness and durability. Understanding the critical importance of operator safety, these models incorporate high-quality materials, components, and craftsmanship. Custom designs are also available in higher capacities or unique configurations such as compression-only frames.

AVAILABLE MODELS

600 kN - 2000 kN Force Capacities

DX and HDX

DX: 600 kN | HDX: 1000 kN Capacities

Taking advantage of the time-tested two space design, the DX and HDX are designed for tension, compression, bend/flex, and shear testing without needing to remove application specific fixtures from the compression test space in order to perform tension tests.

KPX

1500 kN & 2000 kN Capacities

Designed for high-capacity tension, compression, bend/flex, and shear testing, the KPX Models feature an ultra-large single test space and adjustable crosshead options.

Advanced Technology in a Modern Design

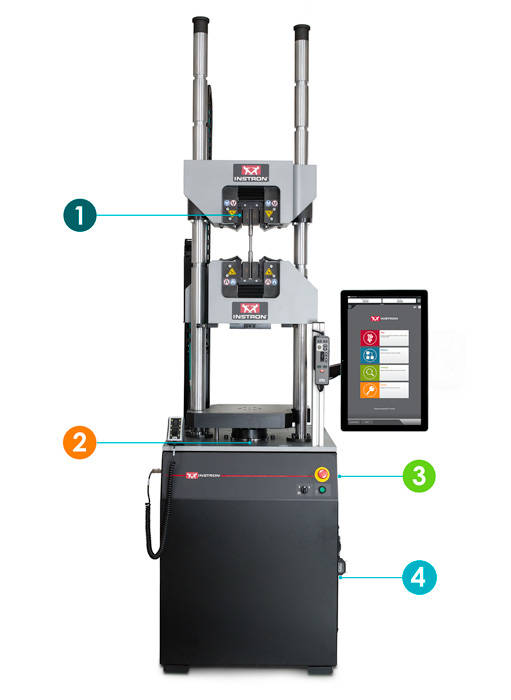

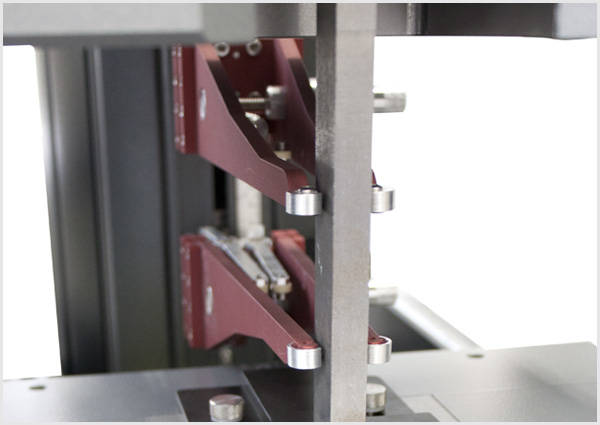

Open Front Hydraulic Grips

Designed with an open front, the hydraulic grips and crossheads provide an efficient gripping solution. Specimens can be loaded without jogging the actuator or adjustable crosshead.

Load Cell

Critical load data is measured directly from the center of the loading axis by a precision strain gauge load cell system. Load data is unaffected by actuator friction allowing the hydraulic drive system to be sealed.

Variable Pressure Pumping System

The V-Series variable pressure pumping system supplies pressure on demand. During the test, the pump output increases as the testing load is increased. Between tests, the system remains at a low idle pressure. The V-Series also provides operating pressure for the hydraulic grips.

5900 Control Platform

An integrated 5900 control platform provides high speed, closed-loop servo control, and data acquisition on load, extension, and 3 optional input channels. Standard features include a single-range measuring system, ethernet communications, and automatic calibration and recognition of transducers.

POWERED BY BLUEHILL® UNIVERSAL

The Next Generation in Materials Testing Software

Bluehill Universal is built from the ground up for touch interaction. The Operator Dashboard features large touchpoints to make the user experience simpler and smarter. Easy-to-understand icons and workflows make it easy to train new or experienced users, simplify operator training, and allow you to start testing even faster than ever before.

System controls are now closer than ever before with an all-new ergonomic handset, mounted directly to the frame. Operators can use the handset in the mounted position or removed from its dock.

With 2 user-defined ‘Soft Key’ buttons, the operator can initiate a variety of commands. The Soft Keys can be defined per method, allowing for customization for each test.

The Fine Position adjustment thumbwheel with tactile feedback allows for precision positioning of the crosshead in 4 μm increments when performing sensitive testing.

Specimen Protect prevents unwanted forces from being applied to the specimen by automatically making fine adjustments to the crosshead, protecting your valuable specimen from damage.

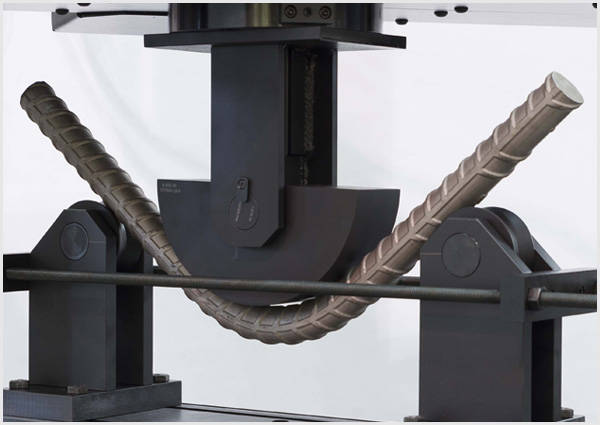

ACCESSORIES

GRIPS, FIXTURES, AND INSTRUMENTATION

Industrial Series systems can be extended with various accessories to meet the changing needs of your laboratory. Standard accessories may be fit to your system to perform common materials tests including tensile, compression, bend/flex, and shear. Customized fixtures are also available for specialized testing applications.

High-Capacity Testing Expertise

A Manufacturing History Dating Back to the Late 1800s

The global expertise of Instron® came about through the merging of recognized materials testing equipment companies including Schenck, Wolpert/Amsler, Riehle, Baldwin, and SATEC™. The Industrial Series leverages this proud heritage with a load cell measuring system, instrumentation, control electronics, accessories, and industry-preferred materials testing software to provide the ultimate high-capacity testing platform.