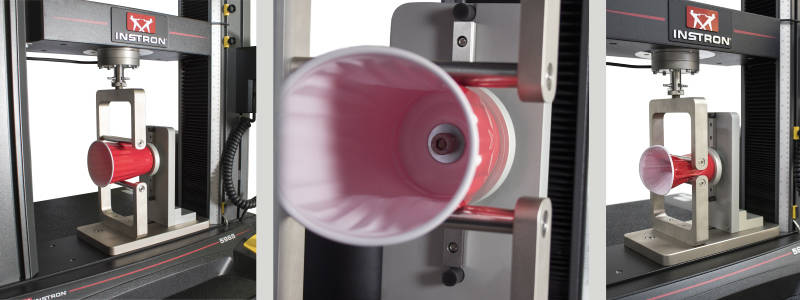

Custom Fixture for Plastic Drinkware

Reducing the cost of these plastic cups comes down to using less material or different formulations, risking production of an inferior quality product whether perceived or actual. Creating a durable product with the lowest material costs allows a company to be competitive on price and also maintain margins. This is where materials testing becomes a critical phase in product design. Being able to accurately test existing products to create a baseline and compare those results to new product revisions is the best way to qualify new designs.

Typically, a simple top to bottom compression test is how these cups are tested, however this does not accurately reflect how drinkware is used. This is where our custom solutions group came in. Recently we completed a project for a leading plastics manufacturer that wanted to test cups the way they are used in the world, that being sidewall compression or how a hand typically grasps a cup. The difficulty of this application stems from the conical frustum shape of the cups. If the cup was tested by laying it on its side on the lower compression platen, the upper platen would first come into contact with the rim of the cup, not the sidewall. This would not mimic actual use (see image to the right).