Dies (Rheology)

A die is a solid piece of hardened steel or tungsten carbide that is finely machined into a cylindrical shape before a cylindrical hole (capillary) is bored through its center, normally by means of electro-erosion techniques. The term ‘capillary’ is sometimes used to indicate the whole die. Dies can be made of different materials such as stainless steel (Stavax) or nickel alloys (Hastelloy) for use with corrosive samples. The sample under test flows out through the capillary. Dies for rheology are used in melt flow instruments and capillary rheometers. They come in a range of different “geometries” to suit different applications and meet the requirements of different standards.

Dies are described by the length and diameter of the capillary, and by the shape of the capillary inlet. Dies are often described by their ‘length over diameter ratio’ or ‘L/D’ and entry angle: e.g. if the capillary length is 20 mm and the diameter is 1 mm, with an inlet consisting of a 90°-opening cone, it will be described as a die with 1-mm diameter capillary, L/D= 20, conical 90° inlet. A flat inlet corresponds to 180°. Special dies can be machined having a very short capillary, normally in the range of 0.25 mm: they are called ‘orifice dies’ or ‘zero-length dies’ and can be used for direct measurement of entrance pressure drop.

The standard die for melt flow tests has a capillary with a diameter of 2.095 mm and a length of 8 mm, with a flat inlet. Special methods call for longer dies, also with conical inlet (ASTM D3364 for tests on PVC).

Dies for capillary rheometers range in diameter from less than 0.5 mm to more than 2 mm, from ‘zero-length’ up to 40 mm or more in length. Inlet shape is normally flat or 90° conical.

Standards recommend for Bagley correction at least two different dies with same capillary diameter and different lengths, while other combinations are required for different applications (e.g. two dies with same L/D for Mooney wall slip evaluation).

References

- ISO 11443: 2005 “Determination of the fluidity of plastics using capillary and slit-die rheometers”

- ISO 1133:2005 "Plastics - Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics”

- ASTM D3835-09 “Standard Test Method for Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer”

- ASTM D1238-10 "Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer“

Capillary Rheometer Systems

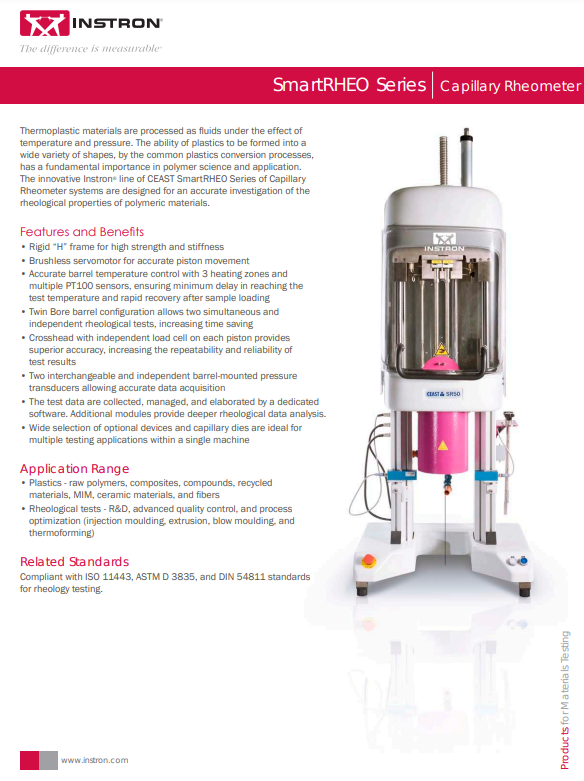

The innovative Instron® line of CEAST SmartRHEO Series of Capillary Rheometer systems are designed for an accurate investigation of the rheological properties of polymeric materials.

CEAST SmartRHEO Series: Capillary Rheometer Systems

Thermoplastic materials are processed as fluids under the effect of temperature and pressure. The ability of plastics to be formed into a wide variety of shapes, by the common plastics conversion processes, has a fundamental importance in polymer science and application. The innovative Instron® line of CEAST SmartRHEO Series of Capillary Rheometer systems are designed for an accurate investigation of the rheological properties of polymeric materials.

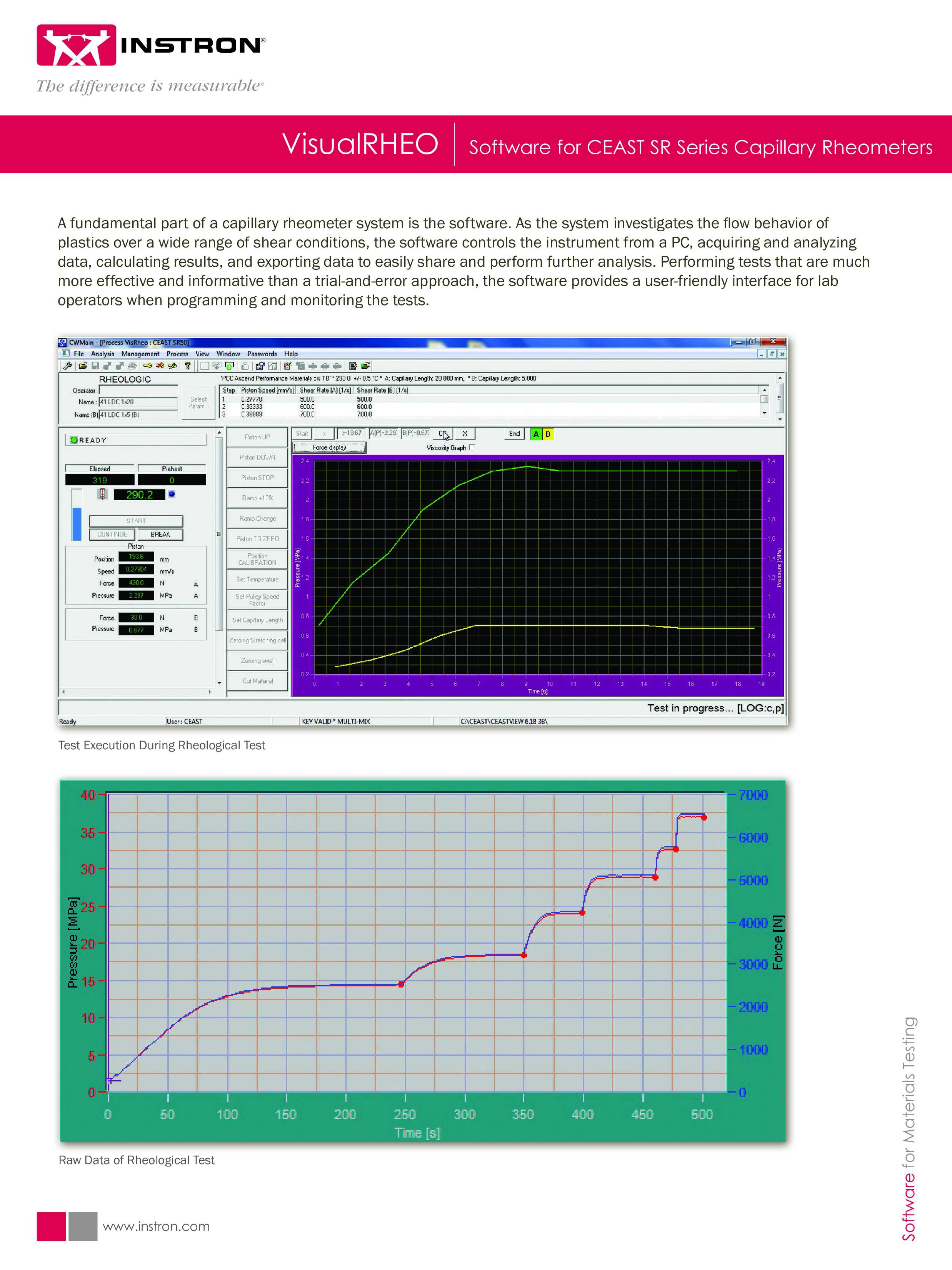

VisualRHEO | Software for CEAST SR Series Capillary Rheometers

A fundamental part of a capillary rheometer system is the software. As the system investigates the flow behavior of

plastics over a wide range of shear conditions, the software controls the instrument from a PC, acquiring and analyzing

data, calculating results, and exporting data to easily share and perform further analysis. Performing tests that are much

more effective and informative than a trial-and-error approach, the software provides a user-friendly interface for lab

operators when programming and monitoring the tests.