Melt Flow Rate (MFR, MVR)

The Melt Flow Rate is a measure of the ease of flow of melted plastic and represents a typical index for Quality Control of thermoplastics. Originally called Melt Flow Index or Melt Index (typically for polyethylene, but applied to a variety of materials), the standard designation today is Melt Mass-Flow Rate or MFR, which is a mass flow expressed (SI units) in g/10min. An alternative quantity is the volume flow expressed (SI units) in cm3/10min, called Melt Volume-Flow Rate or MVR. MVR multiplied by the melt density (i.e. density of the material in the melted state) gives MFR.

Typical Melt Flow instruments are compact and easy to use. The basic principle is that a thermoplastic sample (originally in the shape of granules, powder or flakes) is made fluid by heating and forced to flow out of a cylinder through a capillary die. The extruding piston is loaded with dead weights, normally up to 21.6 kg. MFR (and MVR) are obtained under standard conditions of temperature and applied load, defined for each type of material, and normally using a fixed type of die (inner diameter 2.095 mm, length 8 mm). The result must always specify the test conditions because it’s strongly dependent on those.

MFR and MVR are typically used in Quality Control labs and Production Control labs. The basic procedure foresees a manual timing, cutting and weighing of the extruded material, giving directly a value of MFR. Semi-automatic procedures allowed by modern instruments are based on direct measurements of piston displacement, hence they give directly a value of MVR. Melt density can be typed in or measured, and therefore MFR results are also obtained. Semi-automatic procedures can achieve a much higher accuracy and guarantee a wider range of measurable flow rates. More advanced methods foresee the application of several loads during the same test, each one giving a MFR (MVR) result. This is called a multiweight test and gives additional information on the sample, with some insight on the shear dependence of viscosity. A single-weight MFR test can be correlated with average molecular mass, while the shear dependence depends on the molecular mass distribution.

Melt flow rate is a quick tool to compare batches of the same material or to estimate flow properties of different materials (typically for extrusion processes), when a deep understanding of material properties is not required. A true rheological characterization can be carried out by means of rheometers. Melt flow rate is inversely proportional to (shear) viscosity, but is not used to determine the latter (can give just a rough estimation).

References:

- ISO 1133:2005 "Plastics - Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics”

- ASTM D1238-10 "Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer“

Testing Equipment

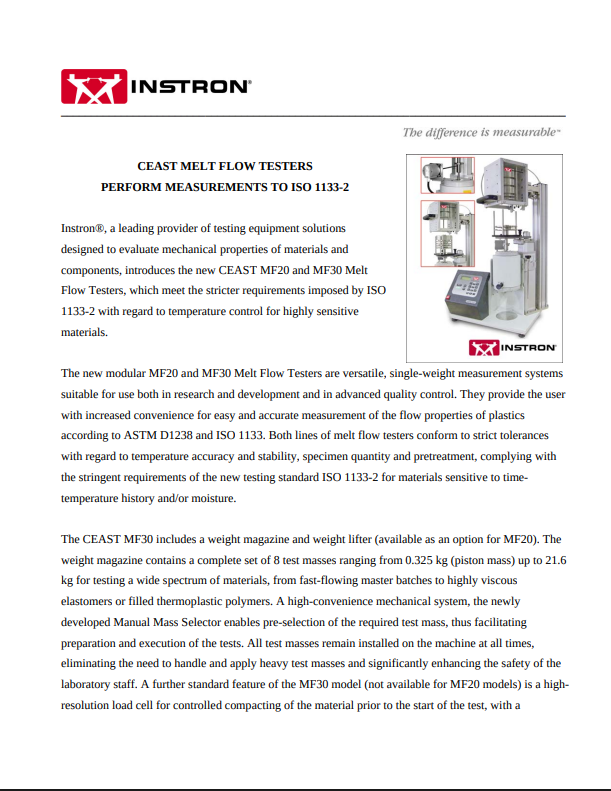

Melt Flow tests are performed on melt flow testers table top machines such as Instron's MF20 and MF30. These machines are available in a variety of different sizes. Depending on the number of masses needed for your material, the machines can be equipped with automatic weight lifter.

CEAST Melt Flow Series Brochure

Flow properties of molten plastics are a critical characteristic requiring good knowledge and control. The Instron® Melt Flow Testers are specifically designed for easy

and accurate measuring of the Melt Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate (MVR). CEAST Melt Flow Testers range from systems that perform a simple

manual test procedure to semi-automated testing systems performing multiple weight tests.

CEAST Melt Flow Testers (MF20 and MF30)

The CEAST line of melt flow testers now includes the MF20 and MF30 Melt Flow Testers, which meet the stricter requirements imposed by ISO 1133-2 with regard to temperature control for highly sensitive materials.

CEAST MF Series Brochure

Flow properties of molten plastics are a critical characteristic requiring good knowledge and control. The Instron® Melt Flow Testers are specifically designed for easy and accurate measuring of the Melt Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate (MVR). CEAST Melt Flow Testers range from systems that perform a simple manual test procedure to semi-automated testing systems performing multiple weight tests.

Instron® Professional Services CEAST Melt Flow and HDT Vicat Verification Services

Preventative maintenance and verification of your Melt Flow or HDT Vicat Testing System helps avoid potential risk exposure from inaccurate test results that can affect the quality of your product to market.To report accurate and repeatable results, it is important to ensure your materials testing system is operating at peak performance and verified in conformance with the relevant material testing standards.