ASTM E208 Drop Weight Test for Nil-Ductility Temperature of Ferritic Steel

The ASTM E208 drop weight test is used to determine the nil-ductility transition (NDT) temperature of ferritic steels 5/8 inch thick (15.9 mm) and over. The NDT temperature is the temperature at which the fracture mode of steel changes from ductile to brittle. At temperatures above the NDT a piece of steel will stretch or deform in a ductile manner before fracturing when loaded to its ultimate tensile strength. At temperatures lower than the NDT that same piece of steel will fail in a brittle manner when loaded to its yield strength (roughly half of its ultimate tensile strength). Once a brittle failure begins the crack will continue to grow until it runs out of material, the pressure is released or it encounters steel that is more ductile.

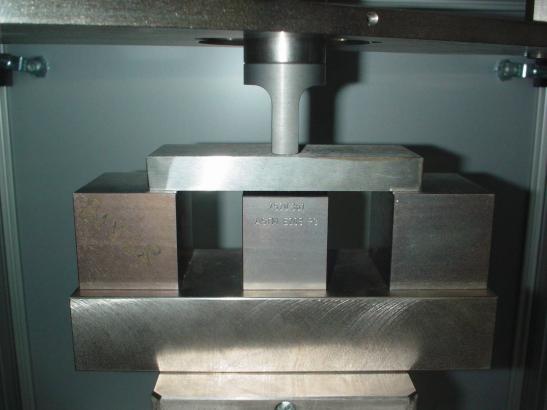

To find out the steel’s NDT temperature, beam specimens are prepared according to ASTM E208 and subjected to a single impact from a drop weight test system. The falling weight tester Model 9450 is suitable for this test. This model is capable of testing specimens with an impact energy from 0.59 – 757 J (0.44 to 558 ft-lb). It is capable of testing type P2 specimens 19 x 130 x 50 mm (0.75” x 5” x 2”) and type P3 specimens 16 x 130 x 50 mm (0.62” by 5” by 2”). When coupled with the Data Acquisition System, a full load - time - displacement - energy data curve and tests results can be captured for each test through Bluehill Impact software.

9400 Series Drop Tower Brochure

Instron Drop Towers are used to develop, fine tune, and validate material models. Testing materials under real impact conditions is a crucial step prior of product design. Using the characterization data obtained with the Instron 9400, coupled with customer supplied high-speed video, you can have confidence in your results and deliver new materials to your customers faster. Our Drop Tower impact systems, fixtures, and tups are designed to meet a wide range of applications and testing standards including: ISO, ASTM, ANSI, Airbus, Boeing, BSI, DIN, EN, FDA, Ford, GM, JIS, NASA, GOST, and more.

- Produtos

- 02/05/2020

- 763.1 KB