EN 2597 Carbon Fiber Reinforced Plastics. Unidirectional Laminates. Tensile Test Perpendicular to the Fiber Direction

EN 2597:1998 is a testing standard that specifies the method of determination of the ultimate tensile strength, tensile modulus, Poisson’s ratio, and strain at failure in tension of carbon fiber reinforced plastics in the form of unidirectional laminates. EN 2598 is used for product development and quality control by a range of manufacturers who use carbon fiber laminates, including the aerospace, automotive, wind energy, and construction industries. This method is only applicable to specimens where the axis is perpendicular to the direction of the fibers. Testing when the axis is parallel to the fiber direction calls for the use of EN 2561.

Materials Testing System

The strength of composite specimens with fibers oriented perpendicular to the loading direction (axis) are normally much lower than the strengths of specimens where the fibers are oriented in the loading direction. Hence, the test forces are much lower. However, since testing to EN 2597 is normally combined with a range of other, higher force tests on composite materials, an electromechanical floor model testing machine such as Instron's 6800 Series will be the most suitable solution. The large (1000:1) force measurement range of the 5980 means that both high and low force tests can be carried out without the need to change load cells. A table model electromechanical machine may have sufficient capacity for testing lower strength materials, such as glass fiber.

| EN 2597 Test Setup | |

|---|---|

6800 Series Universal Testing System |

|

Bluehill Universal Software |

|

2580 Series Load Cell |

|

2742 Series Hydraulic Wedge Grips |

|

AVE2 Non-Contacting Extensometer |

|

Grips

Moving body grips meet the requirements of the standard and are available in both manually and hydraulically operated configurations.

| EN 2597 Testing Accessories | |

|---|---|

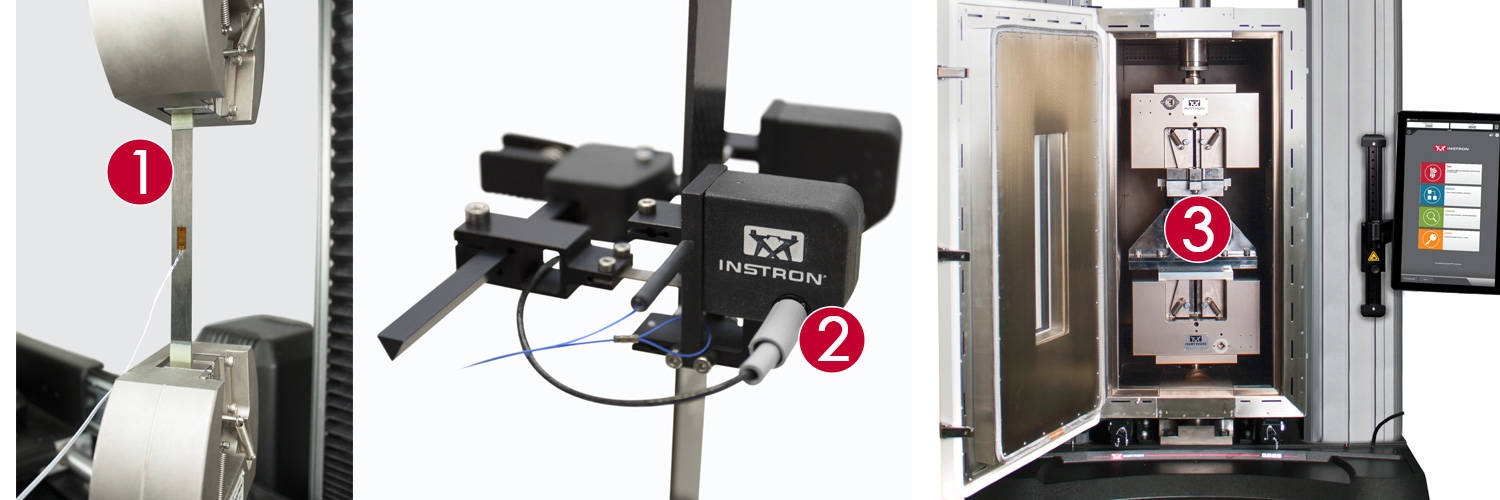

Strain Gauge |

|

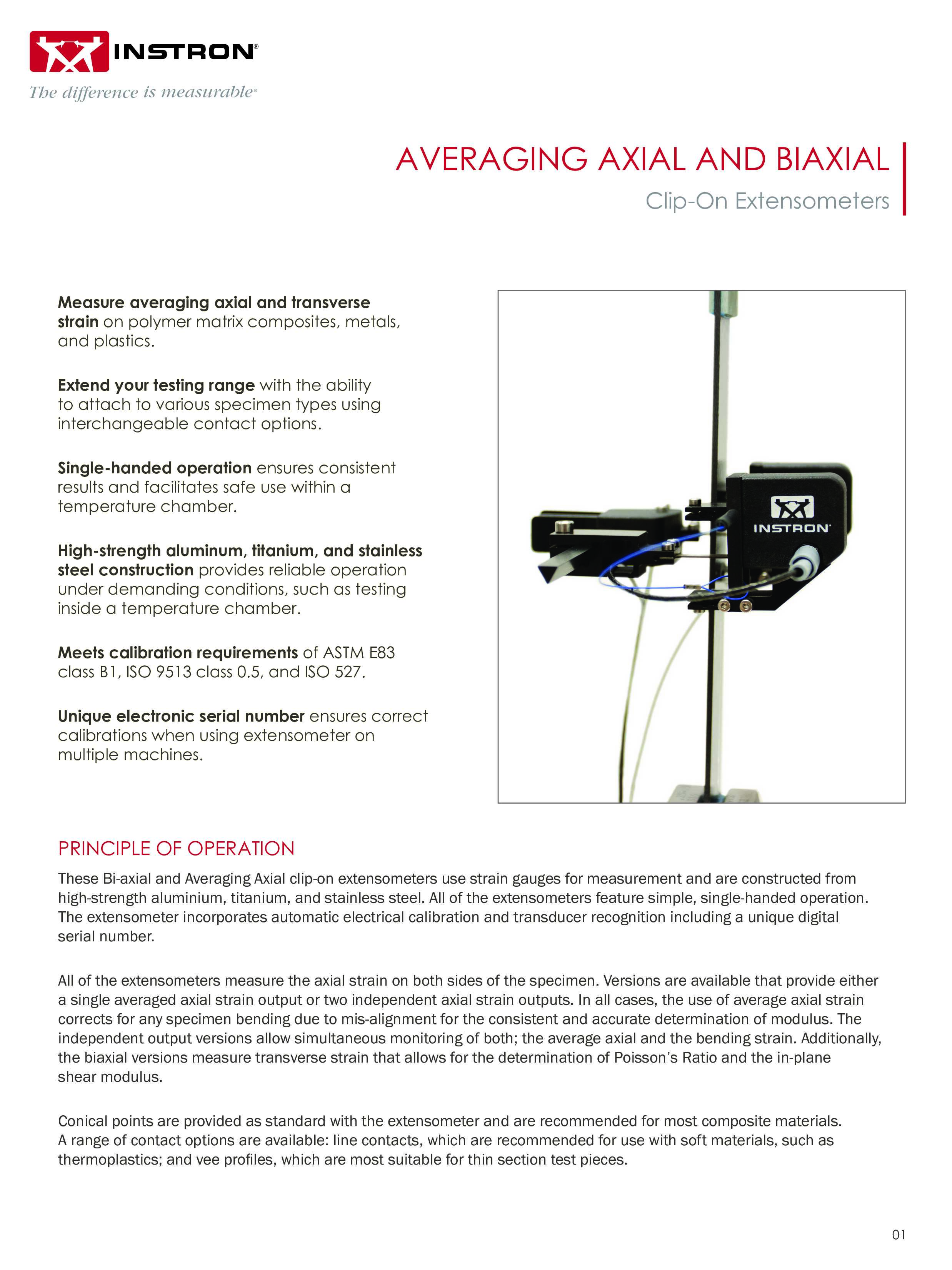

Biaxial Clip-On Extensometer |

|

Environmental Chamber |

|

Strain measurement devices include strain gauges and extensometers. Strain gauges can be connected to the testing machine via easy-to-use strain gauge adapters. A range of suitable contacting extensometers for axial and bi-axial strain measurements are available. When strain at failure is required, a non-contacting strain measurement solution such as Instron's AVE2 is preferred. When tests need to be conducted at high or low temperatures, a temperature chamber along with grips capable of operation inside the chamber are required.

Testing Tips and Tricks

- Obtaining consistent results when testing composites requires accurate alignment of the test specimen. Instron testing frames and accessories provide excellent alignment.

- Bluehill Universal software comes provided with one free applications module upon purchase. The composites module includes a pre-defined EN 2597 test method.

- To read the test method in full, purchase EN 2597:1998