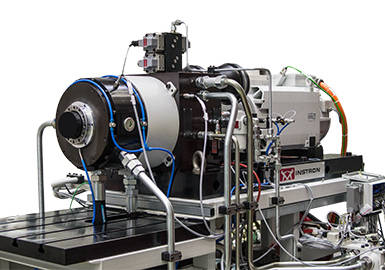

Shock Absorbers Impact Test

The automotive industry remains one of the most common and vulnerable to impact events. Depending on the component, impact damage can have a minor effect on appearance or lead to a major failure in vehicle safety. Both car assemblers and OEM part suppliers must comply with strict safety standards in order to produce high-quality products. Automotive test standards and regulations place an emphasis on impact performance of assemblies and components.

Learn more about our automotive solutions