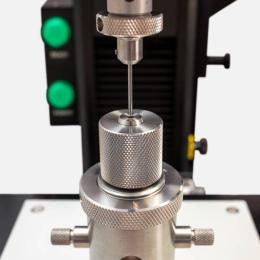

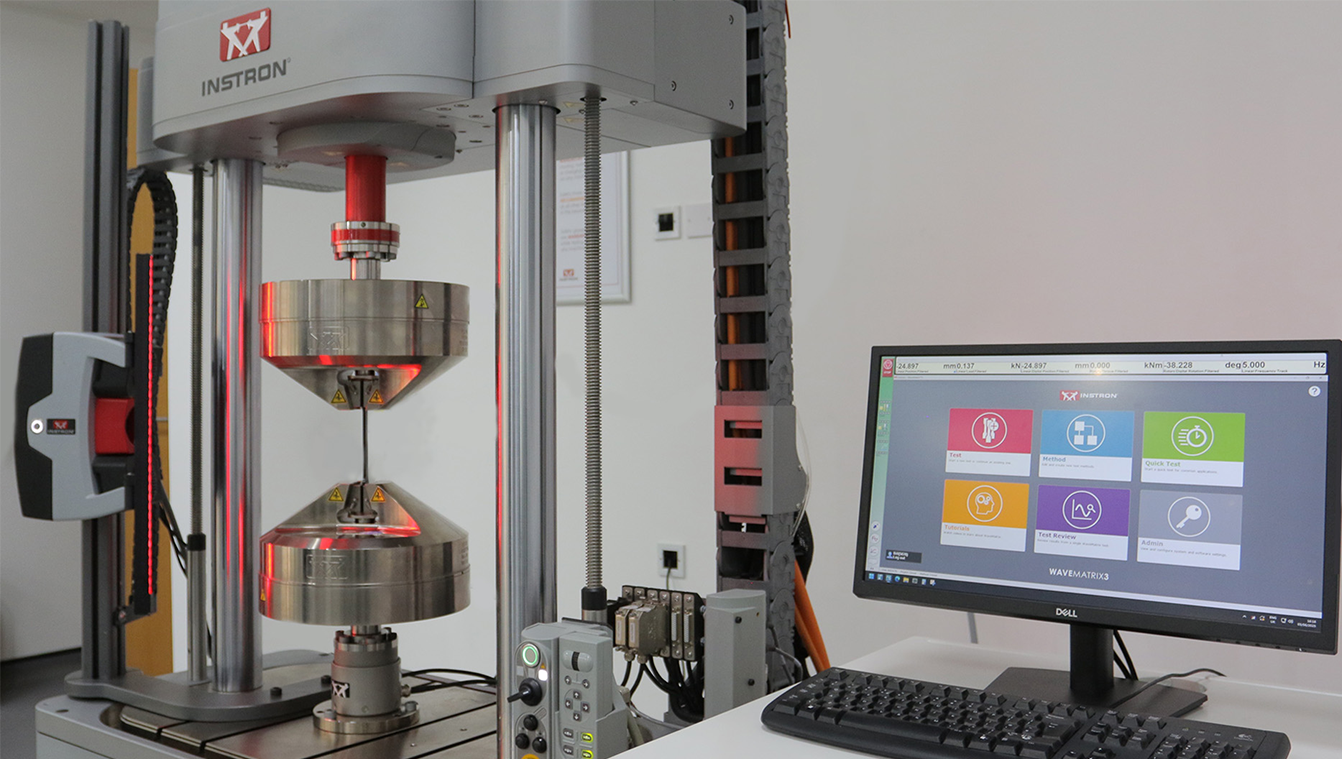

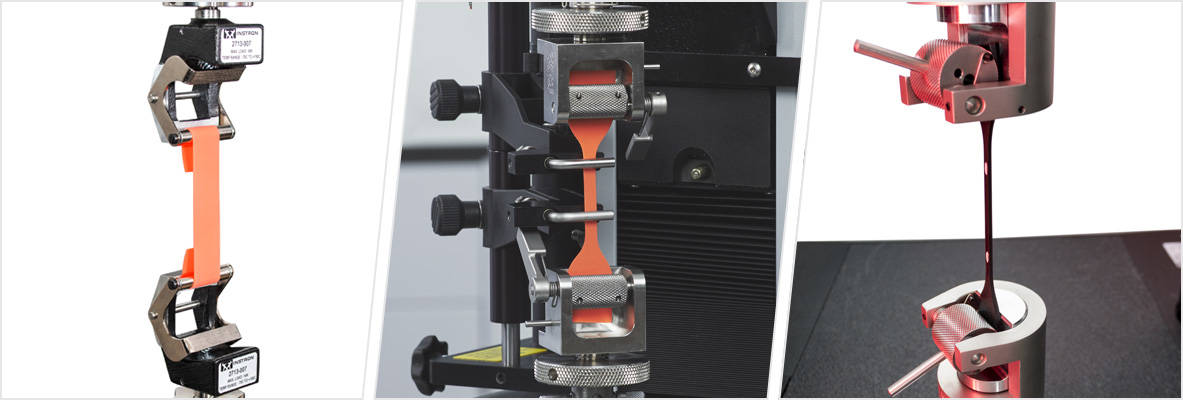

軸向夾持式引伸計

用於靜態應變數

Instron 的靜態軸向夾持式引伸計是一種測量應變的快速簡便的解決方案,適用於各種材料,如塑膠、金屬和複合材料。 我們數十年的應變數經驗幫助我們優化了這些設備的設計,包括:輕巧、堅固的交叉支撐設計,消除了物理變形引起的誤差;內置保護,以減少設備過度伸展造成的損壞;以及設備臂,其設計需要最小的力即可保持與試樣的連接,從而最大限度地減少測試過程中的刀口滑動。所有引伸計均符合 ASTM E83 和 ISO 9513 標準,並附有校準證書,顯示每個裝置在出廠校準時的具體性能。

2630-100 系列

工作原理

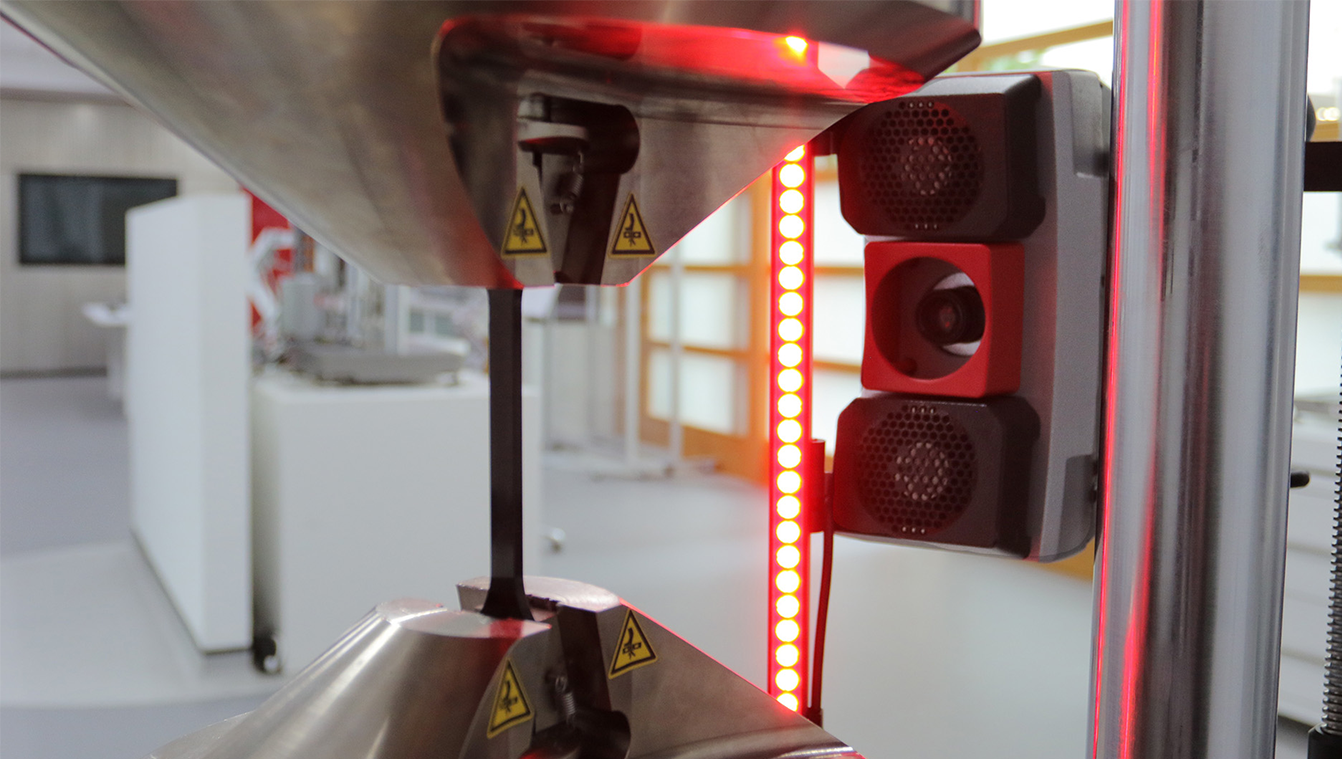

2630 系列引伸計可以準確、一致地安裝或安裝到位,標距長度鎖定裝置在安裝後會自動釋放,確保作的速度和可靠性。這種獨特的“錐形閂鎖”機制還克服了在開始測試之前必須移除銷釘或夾子的問題,或者在引伸計意外鎖定在標距長度處的情況下進行測試。

特性和優勢

- 堅固的橫撐設計,作力小

- 獨特的專利錐形閂鎖系統

- 精確、固定的標距長度,帶自動校準裝置

- 可互換的快速連接彈簧夾

- 用於對小直徑試樣精確對中的定心導軌

- 非常適合在 -100 °C 至 200 °C 之間的溫度櫃中使用

- 適用於單調和低速率循環測試的閉環應變控制

- 堅固的結構允許引伸計在大多數材料發生故障時保持開啟狀態

应用范围

- 金屬測試“n 值”

- 彎曲或壓縮測試

- 硬質塑料測試

- 浸入式測試

- 複合材料

| 可用型號 | ||

|---|---|---|

貨號 |

標距長度(公制) | 行程 (軸向) |

| 2630-120 | 8 毫米 | ±50% |

| 2630-101 | 10 毫米 | ±10% |

| 2630-102 | 10 毫米 | ±50% |

| 2630-105 | 25 毫米 | ±10% |

| 2630-106 | 25 毫米 | +50% |

| 2630-107 | 25 毫米 | +100% |

| 2630-111 | 50 毫米 | ±10% |

| 2630-112 | 50 毫米 | +50% |

| 2630-113 | 50 毫米 | +100% |

| 票價 2630-123 | 75 毫米 | +10% |

| 2630-117 | 80 毫米 | +10% |

| 2630-118 | 80 毫米 | +50% |

| 2630-119 | 100 毫米 | +50% |

貨號 |

標距長度(美國習慣) | 行程 (軸向) |

| 2630-121 | 0.3 英寸 | ±50% |

| 2630-103 | 0.5 英寸 | ±10% |

| 2630-104 | 0.5 英寸 | ±50% |

| 2630-108 | 1.0 英寸 | ±10% |

| 2630-109 | 1.0 英寸 | +50% |

| 2630-110 | 1.0 英寸 | +100% |

| 2630-114 | 2.0 英寸 | ±10% |

| 2630-115 | 2.0 英寸 | +50% |

| 2630-116 | 2.0 英寸 | +100% |

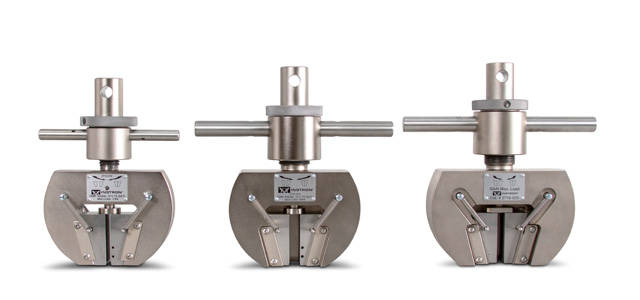

W-6280 系列

用於測試鋼筋和其他棒材

工作原理

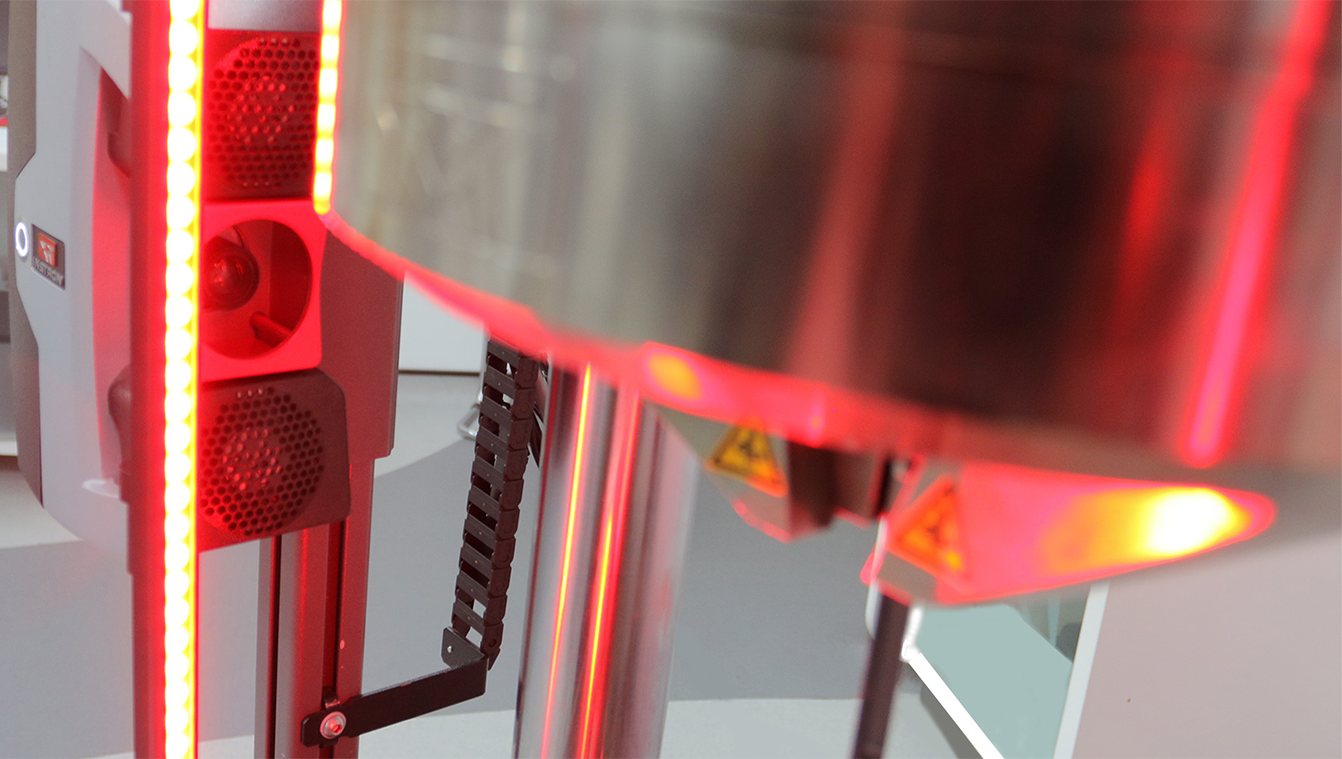

這款長標距夾持式引伸計採用獨特的拉開式設計,減少了試樣斷裂過程中損壞的機會,快速連接套件(隨附)可輕鬆安裝在試樣上。由於 W-6280 系列引伸計的框架尺寸較大,因此需要雙手作才能將儀器連接到試樣上,因此這些引伸計仍然依靠銷釘來設置標距長度。

应用范围

- 載荷類型:拉伸

- 試樣材料:織帶、紡織材料、焊接接頭、鋼筋

- 試樣尺寸:

圓形:直徑

0 至 58.4 mm 扁平:0 至 12.7 mm 厚 x 31.75 mm 寬 - 額定溫度:-40 °C 至 100 °C

| 可用型號 | ||

|---|---|---|

貨號 |

標距長度(公制) | % 行程 (軸向) |

| W-6280-200 | 200 毫米 | +12.5% |

| W-6280-250 | 250 毫米 | +10% |

貨號 |

標距長度(美國習慣) | % 行程 (軸向) |

| W-6280-8 | 8 英寸 | +12.5% |