Tensile Impact Test Method with Drop Weight Impact Tester

Tensile Impact Test at High Strain Rates

How to Perform Tensile Impact Test

A tensile impact test measures the toughness of polymers using an impact tester for plastic according to the ISO 8256 standard. Polymers that are too flexible or thin for a Charpy or Izod impact test generally require an uniaxial tensile impact test with a relative high strain rate.

When evaluating the elastic response of a material, quasi-static tensile testers are used to determine most of the mechanical properties. However, a wide variety of polymeric materials are sensitive to strain and require an impact tester for plastic that can run a tensile impact strength test at both quasi-static and high velocities.

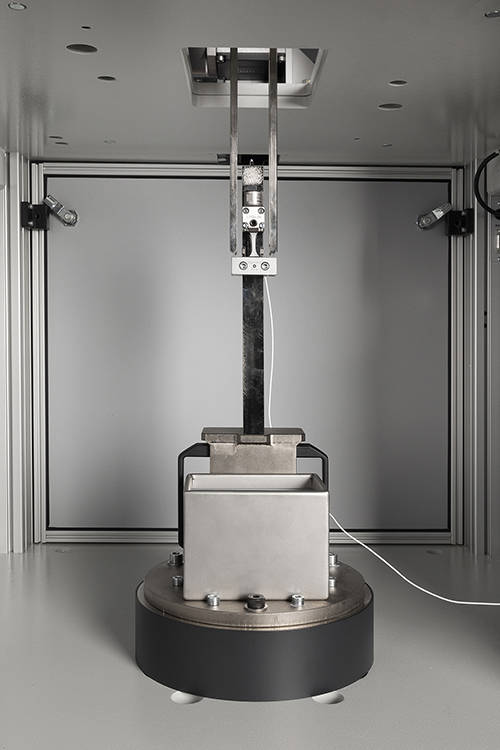

The Instron impact test apparatus can reach a wide range of impact velocities from relatively low (0.7 m/s) to very high (22m/s). Thanks to variable impact masses, the test velocity remains as constant as possible during the elongation of the specimen. Instron’s impact test apparatus covers impact energies between 1 and 1,800 J.

- A dedicated tensile-impact striker

- A tensile-impact vice equipped with a piezoelectric load cell (up to 2.2 kN) or a strain-gauge sensor (up to 15 kN), a screw grip with V-shaped jaw faces and a calibrated free tensile grip (crosshead)

- A Data Acquisition System with a piezoelectric or strain-gauge channel

With the combined use of a drop weigh impact testing machine equipped with Bluehill® Impact Software, tensile impact accessories, High Speed Camera and Digital Image Correlation software, it is possible to evaluate the longitudinal strain of the specimen when impacted under tensile-Impact conditions.

Instron recommends Photron High Speed Camera Fastcam Mini Series.