木材測試夾具

木材材料的特性分析需要在不同負載條件下進行一系列測試,例如拉伸、壓縮、剪切和彎曲。Instron 提供一系列高性能木材測試夾具,符合相關 ASTM、ISO、EN、JIS 及其他測試標準的要求。

木材材料的特性分析需要在不同負載條件下進行一系列測試,例如拉伸、壓縮、剪切和彎曲。Instron 提供一系列高性能木材測試夾具,符合相關 ASTM、ISO、EN、JIS 及其他測試標準的要求。

Instron ISO 80369 系統建立在具有雙軸功能的單柱 萬能試驗機 之上,旨在支援附錄 B 到 I* 的測試。該系統包括一個額外的壓力感測器以及一個能夠根據標準產生正壓和負壓的控制器。鑒於可以測試的設備範圍廣泛,該系統提供了必要的模組化,以支持測試注射器、IV 集線器、連接器等。

特定的設備夾具有兩種主要配置。第一種是高度靈活的氣動夾具,具有可互換的表面,旨在匹配各種使用者定義的幾何形狀。整個夾具元件安裝在手動 XY 元件上,以確保被測器件和參考連接器之間一致對齊。第二種配置專為支援標準注射器尺寸而設計。在這種設置中,注射器本體由氣動車床卡盤固定,而旋轉魯爾環由可調節的氣動側動夾具固定。

* 附錄 K 於 2024 年發布,目前仍在進行相容性評估。

將測試整合到單個系統中並按順序執行組裝,可提供無與倫比的效率,從而減少評估設備所需的時間並最大限度地減少所需的設備數量。

為了最大限度地延長測試時間,可以移除完全組裝的參考連接器-器件對,以允許應力開裂所需的 48 小時保持時間,而不會失去使用系統的能力。

考慮到其大量費用,該系統可以配置為允許客戶使用現有的參考連接器。為確保正確配合和功能,在系統設計過程中需要提供電流連接器。

用於測試IV集線器和連接器的配置在氣動夾具上提供了一個簡單的安裝模式,允許公司連接自己的表面,使其與設備幾何形狀相匹配。這也使技工所能夠保持敏捷性,輕鬆製作新面孔原型以支持設備概念。

該系統經過適當評級,支援執行變數測試,而不是標準屬性測試,因為它可能需要破壞性測試。這減少了獲得具有統計學意義的結果所需的標本總數。

請填寫下方表格,我們將很樂意與您聯繫並回覆。我們通常會在 1-2 個工作天內回覆線上請求。如需更快回覆,請致電 +886-3-572-2155。

作為首屈一指的延伸計解決方案,AVE3 在

,抗拉、抗壓和彎曲測試的準確度高達 1 微米。AVE3 提供

、複合材料的爆炸性破壞,甚至可在腔室或液浴中進行非環境測試。AVE3 符合

ISO 9513 和 ASTM E83 標準,這表示您可以使用單一裝置可靠地依任何標準進行測試,無需購買

和維護多個夾式裝置。

AVE3 幾乎可以測量所有應用的模量和斷裂應變,包括扁平和圓形樣品的靜態拉伸、彎曲和 壓縮試驗。測量可以在環境條件下進行,也可以在高溫和低溫條件下進行 使用環境箱或液體槽進行測量。無論您測試的是塑膠、金屬、複合材料、紡織品、 薄膜、箔片、彈性體、紙張、組件或生物材料,AVE3 都能提供豐富的功能,以滿足不斷變化的測試需求 並符合以下標準。

鏡頭經過配置並在工廠進行校準,以適用於您獨特的測試設定。光圈和對焦設定已鎖定,以

注意:選擇鏡頭時,請確保您知道最小和最大標距長度要求,以及您計劃測試的試樣範圍的總伸長率。

借助新的 AVE3,您現在能夠執行需要應變控制的測試,包括 ASTM E8 和 ISO 6892。 憑藉準確度的進步和 500 Hz 的資料擷取速率,AVE3 可提供快速的見解,使 測試系統能夠即時回應應變速率的變化 — 確保您擁有符合測試標準的可重複和可比較的 結果。

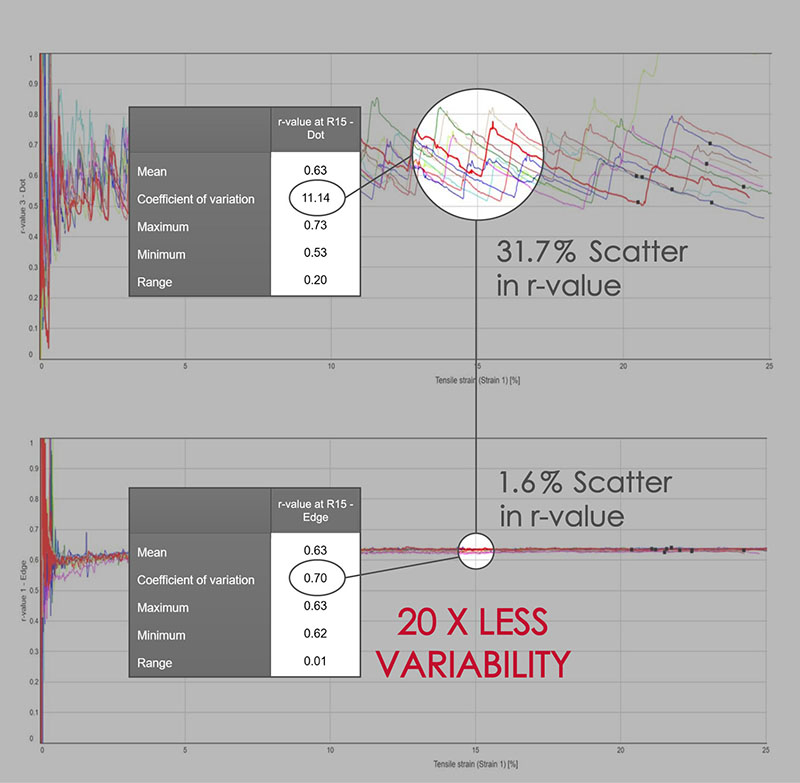

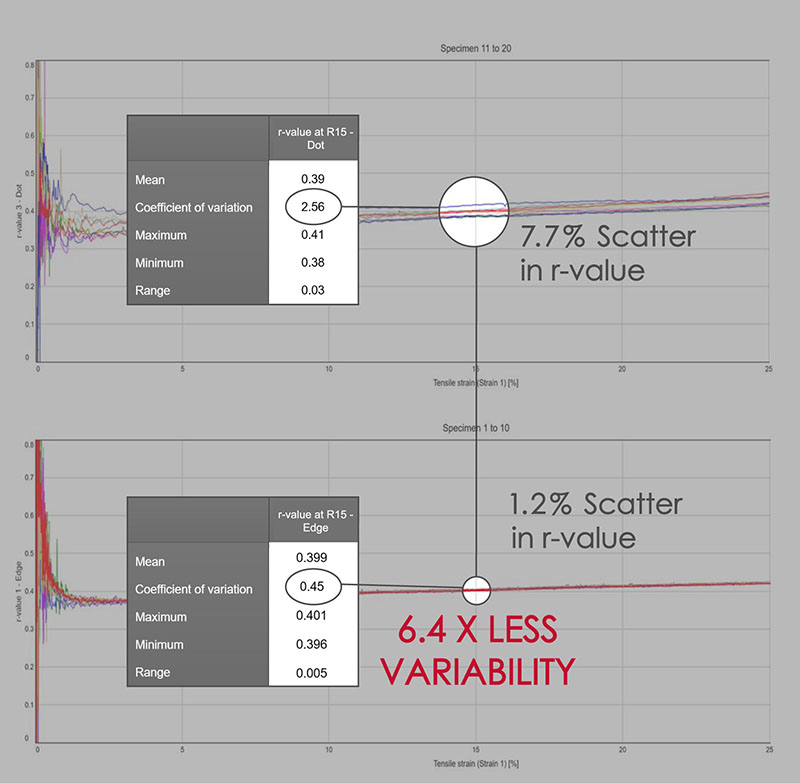

AverEdge32 是 AVE3 的一個可選進階功能,它利用邊緣偵測技術同時 測量沿試樣標距長度 32 個位置的橫向應變。然後,它會即時對它們進行平均, 從而產生平滑且可重複的橫向應變值,這對於計算金屬板的 r 值至關重要。

數位圖像相關 (DIC) 是一種光學技術,可比較被測樣品表面的圖像以生成全場 應變和位移圖。它創建的圖片可用於可視化試樣整個二維表面上的應變和位移。

Instron 的液壓夾具泵專為高負載測試應用提供精確可靠的夾持力而設計,支援負載能力高達 600 kN。

These machines are developed to obtain specimens by punching, using hollow dies of different sizes and contours. Several hundreds of dies can be created by interchangeable socket punches with different profiles and size according to the standards and to the customer needs. Dies are made of steel with hand finished cutting edges and can be provided with ejector for easy removal of the specimen after punching.

Compact design of instrument for an easy and fast preparation

Manual and automatic models obtain specimens of different size and geometries for a wide range of plastics testing applications

High level of results repeatability and time saving test procedures

| 型號名稱 | 零件編號 | 支援階段 第 1 階段 – 系統正在全面生產中,技術支援、零件和軟體均可提供。 第 2 階段 – 系統已停止生產。技術支援、服務、零件和軟體均可提供。 第 3 階段 – 系統已停止生產。可提供服務,但零件和軟體可能有限。 第 4 階段 – 系統已停止生產。無法提供服務或零件。 閱讀更多以獲取完整詳情。 |

生產期間 | 可用的軟體升級 這是可操作此系統的最新版本軟體。聯絡銷售討論您的系統軟體升級事宜。 | 可用的系統改造 透過升級至 Instron® 最先進的電子設備和軟體,延長您的 Instron® 測試系統的使用壽命和功能。點擊此處了解更多 |

|---|---|---|---|---|---|

| HV3 | 6911.000 韌體版本 <4.00 | 4 | 1998-2016 | 無 | 否(可折價) |

| HV3 | 6911.000 韌體版本 ≥4.00 | 3 | 1998-2016 | Bluehill HV | 否(可折價) |

| HV6 | 6921.000 韌體版本 <4.00 | 4 | 1998-2016 | 無 | 否(可折價) |

| HV6 | 6921.000 韌體版本 ≥4.00 | 3 | 1998-2016 | Bluehill HV | 否(可折價) |

| HV6A | 6970.000 韌體版本 <4.00 | 4 | 1998-2016 | 無 | 否(可折價) |

| HV6A | 6970.000 韌體版本 ≥4.00 | 3 | 1998-2016 | Bluehill HV | 否(可折價) |

| 水冷卻器 50Hz | 6977.000 | 2 | 2008-2019 | 無 | 否(可折價) |

| 水冷卻器 60Hz | 6977.000.60 | 2 | 2008-2019 | 無 | 否(可折價) |

生命週期通知書:Instron® HDT Vicat HV 系列進入第 4 階段 – 停產產品

折價通知書:Instron® HDT Vicat HV 系列

| 型號名稱 | 零件編號 | 支援階段 第 1 階段 – 系統正在全面生產中,技術支援、零件和軟體均可提供。 第 2 階段 – 系統已停止生產。技術支援、服務、零件和軟體均可提供。 第 3 階段 – 系統已停止生產。可提供服務,但零件和軟體可能有限。 第 4 階段 – 系統已停止生產。無法提供服務或零件。 閱讀更多以獲取完整詳情。 |

生產期間 | 可用的軟體升級 這是可操作此系統的最新版本軟體。聯絡銷售討論您的系統軟體升級事宜。 | 可用的系統改造 透過升級至 Instron® 最先進的電子設備和軟體,延長您的 Instron® 測試系統的使用壽命和功能。點擊此處了解更多 |

|---|---|---|---|---|---|

| HDT 3 Junior | 6910.000 | 4 | 1998-2012 | 無 | 否 |

| HDT Vicat 3 工位 | 6510.000 | 4 | 1999-2001 | 無 | 否 |

| HDT Vicat 5 工位配備 Test-a-matic | 6520.000 | 4 | 1997 | 無 | 否 |

| HDT 300 Vicat | 6860.000 | 4 | 1998-2000 | 無 | 否 |

| HDT 375 Vicat | 6861.000 | 4 | 1998-2000 | 無 | 否 |

| HDT Vicat Auto Plus | 6971.000 | 4 | 2001-2007 | 無 | 否 |

| Vicat 500-D Auto | 7300.000 | 4 | 2001-2003 | 無 | 否 |

| Vicat 500-D Auto | 7302.000 | 4 | 2005-2007 | 無 | 否 |

生命週期通知書:Instron® HDT Vicat 系列進入第 3 階段 – 停產/盡力支援

Thermo-mechanical fatigue (TMF) testing is a complex and demanding strain controlled testing under programmable temperature variations. Instron offers a comprehensive solution for such testing that requires simulating of synchronised heating and cooling of specimens combined with mechanical loading with real time thermal strain compensation. TMF test systems are useful to test the operational efficiency and reliability of turbine components and structures when subjected to simultaneous changes in temperatures and load under laboratory controlled environment. Our state of the art digital servo used with TMF test system envisages independent induction heating and cooling through compressed air and also allows multi zone temperature tracking1. MTL32 proprietary algorithms used with our controllers permit precision heating rates up to 20 °C/s and cooling up to 10 °C/s.

For Universal Testing Systems

Our standard furnaces, mounts, grips, and load string assemblies for universal testing systems allow for testing up to 1200°C in air. Our engineered solutions group is also able to develop solutions to meet higher temperature requirements and additional furnace dimensions.

1200°C Three-Zone Split Tube Furnace

This three-zone split tube furnace features a side entry extensometer port and is manufactured with a wire-wound element for maximum operation up to 1200°C (2200°F). The elements are uniquely formed to provide optimum temperature uniformity, ensuring conformance with testing standards such as ASTM E21, ISO 6892-2, EN10002-5,and EN2002-2. The top and bottom furnace endplates are durable, provide excellent insulation, and include a 20 mm (0.787 in) diameter hole for use with pull rods.

| Specifications | |||

| Specimen Temperature Range | 200 - 1050°C (392 - 1922°F) | ||

| Overall Heated Length | 300 mm (11.81 in) | ||

| Interior Diameter | 75 mm (2.95 in) | ||

Mounting brackets are used to securely attach the furnace to the test system.

| Specifications | |||

| Description | Catalog No. | ||

| Floor Model Standard Furnace Mounting A standard 3-knuckle design furnace mounting that allows for manual adjustments. | CP119938 | ||

| Floor Model Advanced Furnace Mounting The advanced mounting allows for quick and easy fine adjustments of the vertical position of the furnace as well as parallelism to the load string. | CP107737 | ||

Three-Zone Temperature Control Systems

Temperature control systems are designed for controlling the heat output of furnaces. The control systems can be configured to operate nearly any furnace with any one of several different thermocouples types. Three zone control systems are designed for heat-only furnaces with three separate zones of heating elements, and typically three different thermocouples to control those zones.

| Specifications | |||

| Description | Catalog No. | ||

| Type K Control System | 3119-960 | ||

| Type R/S Control System | 3119-962 | ||

| Stepdown Transformer The wall mount 3KVA stepdown transformer assembly provides the ability to operate the 120V, single phase Model TCS3203 3-zone furnace control system from 190/200/208/220V, 50/60Hz power sources. | W-C015-TRAN | ||

Quick-change adapters are typically used in hot tensile applications to provide simplified load train installation. They consist of a button-head washer that is threaded onto the room temperature end of a pull rod. The washer and pull rod are then inserted through a slot in the adapter body.

| Specifications | |||

| Force Capacity | Effective Length | Catalog No. | |

| 90 kN | 6.43 in | W-7556M4 | |

| 10 kN | 5.58 in | W-7556M2 | |

Threaded End Specimen Holders

Catalog No. W-7551-C

Threaded-end specimen holders made of Inconel 713-C rated for a maximum temperature of 1100 Deg. C (2000 Deg. F).

| Specifications | ||

| Specimen Thread Size | Catalog No. | |

| Metric M6 x 1.0 | W-7551-CM1 | |

| Metric M8 x 1.0 | W-7551-CM2 | |

| Metric M8 x 1.25 | W-7551-CM3 | |

| Metric M10 x 1.5 | W-7551-CM4 | |

| Metric M12 x 1.5 | W-7551-CM5 | |

| Metric M12 x 1.75 | W-7551-CM6 | |

| Metric M14 x 2.0 | W-7551-CM7 | |

| Metric M16 x 1.5 | W-7551-CM8 | |

| Metric M16 x 2.0 | W-7551-CM9 | |

| Metric M18 x 2.5 | W-7551-CM10 | |

| Metric M19 x 1.5 | W-7551-CM11 | |

| US Customary 10-24 | W-7551-CU1 | |

| US Customary 10-32 | W-7551-CU2 | |

| US Customary 1/4-20 | W-7551-CU3 | |

| US Customary 1/4-28 | W-7551-CU4 | |

| US Customary 5/16-24 | W-7551-CU5 | |

| US Customary 5/16-18 | W-7551-CU6 | |

| US Customary 3/8-16 | W-7551-CU7 | |

| US Customary 3/8-24 | W-7551-CU8 | |

| US Customary 7/16-14 | W-7551-CU9 | |

| US Customary 1/2-13 | W-7551-CU10 | |

| US Customary 5/8-11 | W-7551-CU11 | |

| US Customary 3/4-10 (Type R3f) | W-7551-CU12 | |

Pull Rods

High temperature pull rods made of made of Inconel 713-C for strength and resistance to corrosion and oxidation. Both ends are threaded 0.75-10m-RH and are compatible with a range of grips, adapters, and specimen holders.

Rated for 9070 kgs (20,000 lbs) load up to 760°C (1400°F) and 1360 kgs (3000 lbs) load at a maximum temperature of 1100°C (2000°F).

| Specifications | |||

| Pull Rod Length | Force Capacity | Catalog No. | |

| 273 mm (10.75 in) | 90 / 26.7 kN | W-7546-C | |

| 330 mm (13.00 in) | 90 / 26.7 kN | W-7547-C | |

High Temperature Tension Wedge Grips

Catalog No. W-7554

One set (2) wedge grip specimen holders made of Hastelloy X. Holders designed for tension-only loading and may be equipped to accept flat specimens from 1.13 mm to 3.18 mm thick (0.005 in to 0.125 in) by 12.7 mm to 22.225 mm wide (0.5 in to 0.875 in). Design of holders requires drilling of holes in specimen end tabs for initial loading and jaw alignment. Centering pin diameter 4.1148 mm (0.162 in). Holders are 70mm (2.75 in) long by 38mm (1.375 in) diameter contain 0.75-10f-RH thread for attachment to pull rods. Jaw inserts ordered separately, selected based on thicknesses of specimens to be tested. See W-7554-A1, -A3, and -A4 below for available inserts and corresponding thickness ranges.

| Specifications | |||

| Specimen Diameter | Pin 4.1148 mm (Pin 0.162 in) | ||

| Specimen Thickness | 1.13 - 3.18 mm (0.005 - 0.125 in) | ||

| Specimen Width | 12.700 - 22.225 mm (0.500 - 0.875 in) | ||

| Temperature Rating | 926°C (1700°F) | ||

High Temperature Wedge Jaw Inserts

One set (two pairs) of high temperature wedge jaw inserts for use with the W-7554 high temperature tension wedge grips.

| Specifications | |||

| Type | Specimen Thickness | Temperature Rating | Catalog No. |

| Smooth-Faced | 0.13 to 1.0 mm (0.005 to 0.040 in) | 926°C (1700°F) | W-7554-A1 |

| Serrated-Faced | 1.0 to 2.0 mm (0.040 to 0.078 in) | 926°C (1700°F) | W-7554-A3 |

| Serrated-Faced | 2.0 to 3.18 mm (0.078 to 0.125 in) | W-7554-A4 | |

Pin and Clevis Holders

Pin and clevis specimen holders are designed for flat specimens that have a hole in each end. The specimen fits into the slot of the holder and is secured by the pin.

Note: Using a specimen that is smaller (thinner) than the slot width specified for a given set of holders can result in misalignment of the specimen.

| Specifications | |||

| Material | Iconel 713-C | ||

| Temperature Rating | 1100°C (2000°F) | ||

| Upper and Lower Fittings | US Customary 3/4 in-10 (Type R3f) | ||

| Coupling Length | 69.9 mm (2.75 in) | ||

| Coupling Diameter | 28.6 mm (1.125 in) | ||

| Available Sizes | |

| Size | Catalog No. |

| 1 mm slot, 3 mm pin | CP112249 |

| 2 mm slot, 3 mm pin | CP112250 |

| 3 mm slot, 4 mm pin | CP112251 |

| 4 mm slot, 4 mm pin | CP112252 |

| 6 mm slot, 6 mm pin | CP112253 |

| 10 mm slot, 10 mm pin | CP112255 |