Hydraulic Power Units

The Perfect Partner for Your Servohydraulic Test System

Instron®’s 3520 series allows you to configure a Hydraulic Power Unit (HPU) to meet all your testing requirements and site conditions with unsurpassed efficiency and low environmental impact. They are used to provide varying flow rates of hydraulic oil at high pressure and are compatible with the full range of Instron’s Servohydraulic Dynamic and Fatigue Testing Systems. The 3520 Series includes model variants producing 210 bar or 280 bar and flow rates from 27 to 118L/min (7.1 to 31.2 GPM).

Low Noise Levels:

Acoustic attenuation system providing noise levels of 58 - 63 dB (A)*.

Low Operating and Power Costs:

The pressure-compensated variable flow pump configuration ensures operating costs are maintained with test flow demand. Combined with high-efficiency Class 1 motors, power costs are kept to an absolute minimum.

Instron 3520 Series Hydraulic Power Units (HPUs) contain a combination of standard features that are not available on other commercial units.

Fully Adjustable Pressure Supply

The 3520 Series Hydraulic Power Units are designed to operate at levels 10% above nominal full pressure to compensate for pressure losses in long pipe work runs between the HPU and test station(s).

Clean Oil

With oil cleanliness vital to performance and longevity of servo-controlled hydraulic systems, Instron provides 2-micron pressure line filtration on every HPU as standard - a feature omitted by other manufacturers.

Wide Ranges of Flow Rates

Wide ranges of flow rates are available to suit every single and multi-station test configuration.

Longer Oil Change Intervals

High oil tank volume to flow rate ratios, resulting in longer oil change intervals and reduced system downtime.

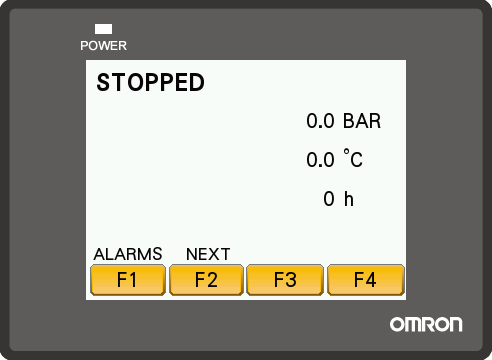

The Programmable Logic Controller (PLC), fitted to every model, provides optimum system control and Hydraulic Power Unit status feedback, as well as a broad range of system interlocks (including oil level, oil temperature, filter condition, and motor temperature).All 3520 Series Hydraulic Power Units feature a full integrated Programmable Logic Controller (PLC) with a conveniently positioned operator interface panel. The PLC provides powerful control features in combination with the advanced circuitry of the HPUs, including:

Alphanumeric indication of Hydraulic Power Unit status, operating pressure and oil temperature.

Control reverts to local operation when the 8800 is disconnected.

Extended Service Functions included flushing and off-line cooling modes.

Adjust temperature and pressure limits to suit your local conditions.

Minimal Electricity Consumption

The Class 1 high-efficiency motors operate at 92 - 95% efficiency (typically), minimizing electricity consumption.

Clean Operation

Leak-free, face-sealed fittings guarantee clean operation.

Minimal Water Consumption

A water-oil plate heat exchanger coupled with a thermostatically controlled water flow valve results in minimal water consumption.

Low Environmental Impact Service

With major serviceable components outside the oil reservoir, there is almost no risk of spillage or need for cleaning when exchanging key components. This also reduces service time and cost.

Hydraulic Power Units (HPUs) Additional Options

Each 3520 Series Hydraulic Power Unit (HPU) can be factory-fitted with a number of options to meet specific site conditions.

Designed with the laboratory environment in mind, the 3520 Series HPUs can be positioned close to the testing machine. Through careful selection of components and materials, Instron is able to provide an optional acoustic attenuation package.

With noise levels as low as 58-63 dB (A)*, depending upon the model selected, combined with an internationally supported leak-free guarantee, Instron advanced noise reduction technology often eliminates the need for a specially-built pump room, providing greater flexibility when locating the Hydraulic Power Unit. The acoustic attenuation system achieves exceptionally low noise specifications while providing ease of maintenance.

Remote air-blast cooling units are available for installations where water cooling is not desirable. The cooling units are designed for ambient air temperatures of up to +37° C (+99° F) and are compatible with all 3520 Series HPUs.

Bladder-type pressure accumulators are available to smooth pump ripples and minimize ring main disturbance with rapidly changing system demands.