A Guide to ASTM F2077-18, Characterization and Fatigue of Spinal Intervertebral Body Fusion Devices

A SUMMARY OF THE STANDARD AND THE DYNAMIC TESTS REQUIRED

Written by Toby Lane

Intervertebral Body Fusion devices are used to promote arthrodesis of a spinal motion segment, following disc degeneration. The implant acts as a support of the anterior column whilst the two vertebral discs grow together and fuse the spine. Intervertebral Body Fusion is an alternative technique to that of Intervertebral Disc replacement.

The tests include:

- Axial-Compression

- Compression-Shear

- Torsion Testing

We recommend that you review the standard to fully understand its requirements. An alternative test for intervertebral body fusion devices is specified in ASTM-F2267.

Challenges of ASTM F2077 Testing:

- Machining/manufacture of test blocks to match specimen shape

- Monitoring of intradiscal height during test

- Assessment of mechanical failure during test

- Avoidance of self-heating in test blocks

- Maintaining load peaks at high frequency

- Test duration for in vivo tests

TEST PARAMETERSAll tests must first be run at ambient temperature in air before being repeated in a simulated in vivo condition using a fluid bath and saline solution at 37°C if required. In vivo testing should not be carried out at a frequency higher than 1Hz.

| Static Tests | Dynamic Tests | |

| Axial-Compression |

|

|

| Compression-Shear |

|

|

| Torsion Testing |

*Cervical (100N), thorasic (300N) and lumber (500N) |

|

TEST RESULTS

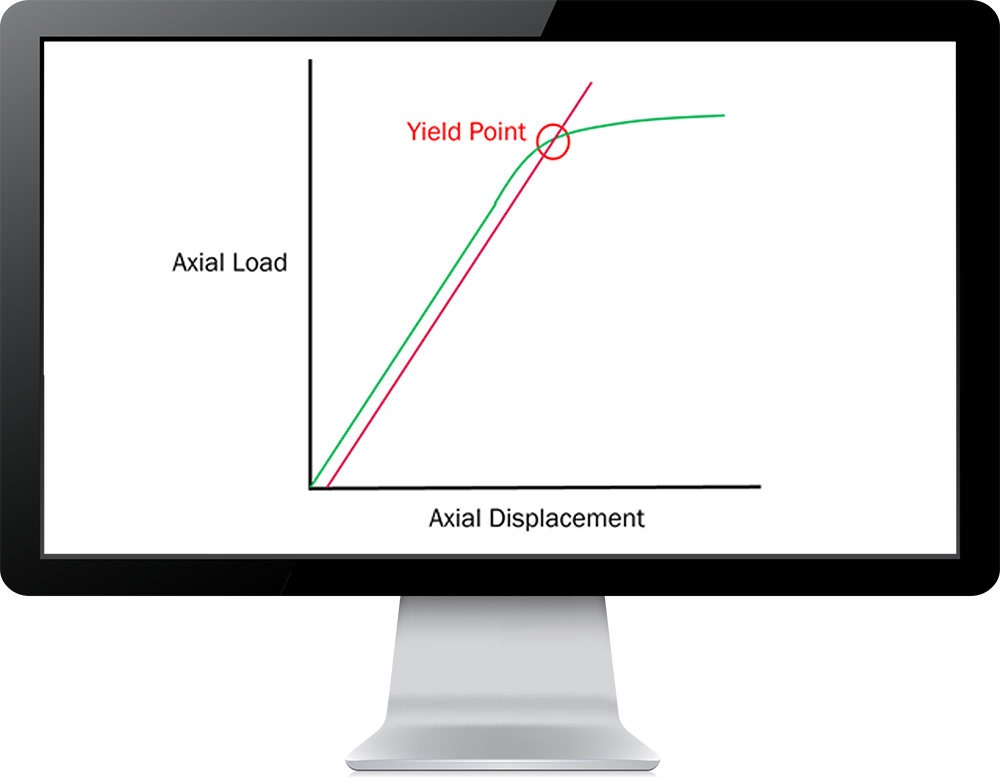

A simple Load vs. Displacement plot is used to characterise each sample for the Static tests.

Static Test Results Table (ASTM F2077)

| Specimen ID | Stiffness (N/mm) | Yield Displacement (mm) | Yield Load (N) | Ultimate Displacement (mm) | Ultimate Load (N) |

| Sample 1 | 10,134 | 1.32 | 11,218 | 1.74 | 14,238 |

| Sample 2 | 10,865 | 1.30 | 11,435 | 1.73 | 15,387 |

| Sample 3 | 11,012 | 1.27 | 11,562 | 1.69 | 13,890 |

| Sample 4 | 10,962 | 1.29 | 11,021 | 1.58 | 14,327 |

| Sample 5 | 10,377 | 1.31 | 10,934 | 1.67 | 15,764 |

| Mean | 10,670 | 1.30 | 11,234 | 1.68 | 14,721 |

| St. Dev | 350.26 | 0.02 | 238.16 | 0.06 | 722.56 |

The data for a minimum of five samples is shown in a table format with the Mean and Standard Deviation shown for each column.

For the Static torsion tests, a torque vs. angle curve is produced instead with a similar table providing the same mean and standard deviation values.

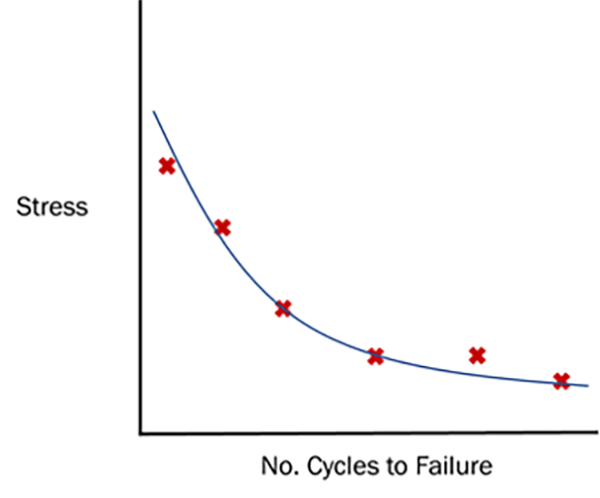

For the Dynamic tests, an SN curve with a minimum of 6 points is required for each specimen type, the aim being to identify the endurance life stress.

Dynamic Test Results Table (ASTM F2077)

| Specimen ID | Maximum Load (N) | Minimum Load (N) | Number of Cycles Achieved | Failure Mode |

| Sample 1 | 5,000 | 500 | 1,004,572 | Fracture |

| Sample 2 | 4,000 | 400 | 4,000,000 | Fracture |

| Sample 3 | 3,000 | 300 | 5,000,000 | Pass without Fracture |

| Sample 4 | 2,000 | 200 | 5,000,000 | Pass without Fracture |

| Sample 5 | 1,000 | 100 | 5,000,000 | Pass without Fracture |

Dynamic Test data is summarised in a table for each sample.

The data point from each sample can be used to produce a plot of Stress vs. No. of cycle to failure.

RELATED CONTENT