Impact Performance of Concrete Beams

There is increasing demand for testing concrete beams in an impact 3-point bend configuration. We recommend a 9400 series drop tower for this testing depending on the maximum energy required. We developed a custom fixture with 300mm span, dedicated tup insert and used the DAS and Bluehill Impact software for data acquisition.

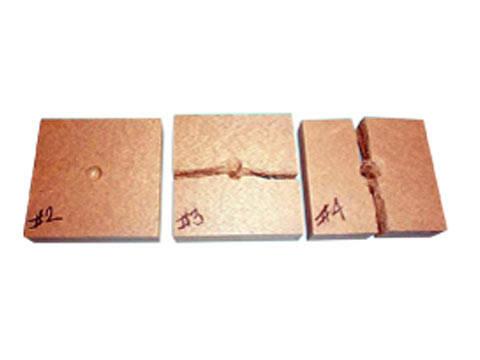

Samples were 400mm x 100mm x 100mm and tested at up to 4.65m/s. The velocity could be increased if required. Tests showed the failure modes and were designed to simulate larger structures which would require much more energy to test than can be achieved in the lab. The types of results compared were total energy absorbed, maximum load, energy to failure and displacement to failure.

The 9400 series is well suited for helping customers determine the performance characteristics of their materials when subjected to an impact event. The information gathered by doing instrumented impact testing can be used to provide the customer with a data baseline whereby they can determine how changes made in the mix of raw materials will perform in real life situations. A broader range of testing could be accomplished with the inclusion of an environmental chamber to study impact characteristics at different temperatures as well as using different fixtures and inserts to simulate other unsupported spans and impact events.

9400 Series Drop Tower Brochure

Instron Drop Towers are used to develop, fine tune, and validate material models. Testing materials under real impact conditions is a crucial step prior of product design. Using the characterization data obtained with the Instron 9400, coupled with customer supplied high-speed video, you can have confidence in your results and deliver new materials to your customers faster. Our Drop Tower impact systems, fixtures, and tups are designed to meet a wide range of applications and testing standards including: ISO, ASTM, ANSI, Airbus, Boeing, BSI, DIN, EN, FDA, Ford, GM, JIS, NASA, GOST, and more.

- Produtos

- 02/05/2020

- 763.1 KB

9400 Series Dashboard Brochure

Bluehill® Impact is built from the ground up for touch interaction. The Operator Dashboard features large touchpoints to make the user experience simpler and smarter. Easy-to-understand icons and workflows make it easy to train new or experienced users, simplify operator training, and allow you to start testing even faster than ever before

- Produtos

- 08/01/2019

- 2.35 MB