Compression Set

The extent to which rubber is permanently deformed by a prolonged compressive load (ASTM D-395). Should not be confused with low temperature compression set.

2501 Series Compression Platens

These easy-to-install compression platens are precisely machined fixtures that are designed for even distribution of compression loads during a test.

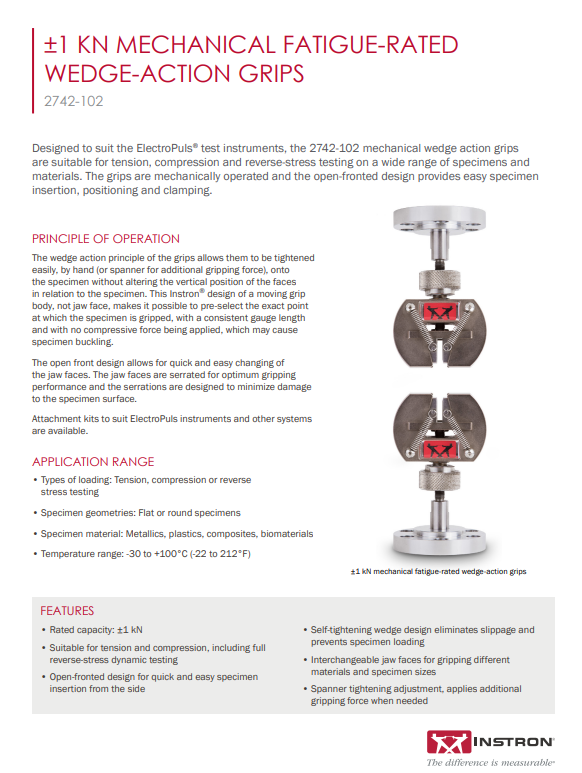

2742-102 MechanicalGrips

Designed to suit ElectroPuls test instruments, the 2742-102 mechanical wedge action grips are suitable for tension, compression and reverse-stress testing on a wide range of specimens and materials. The grips are mechanically operated and the open-fronted design provides easy specimen insertion, positioning and clamping.

A Review of Current In-Plane Composites Compression Testing

The compressive modulus and/or strength of a composite material are critical parameters for many structural uses. The factors that determine the compression strength are complex and the values of compressive strength for a composite can be much lower than values for tensile strength. One of the challenges in the compression testing of composite laminates is in understanding the various test types and standards. This white paper seeks to document and explain this field.

Composites Test Fixtures: Open Hole Compression

Composite Test Fixtures Open-Hole Compression testing is preformed on multi-directional polymer matrix composite laminates reinforced with high modulus fibers.

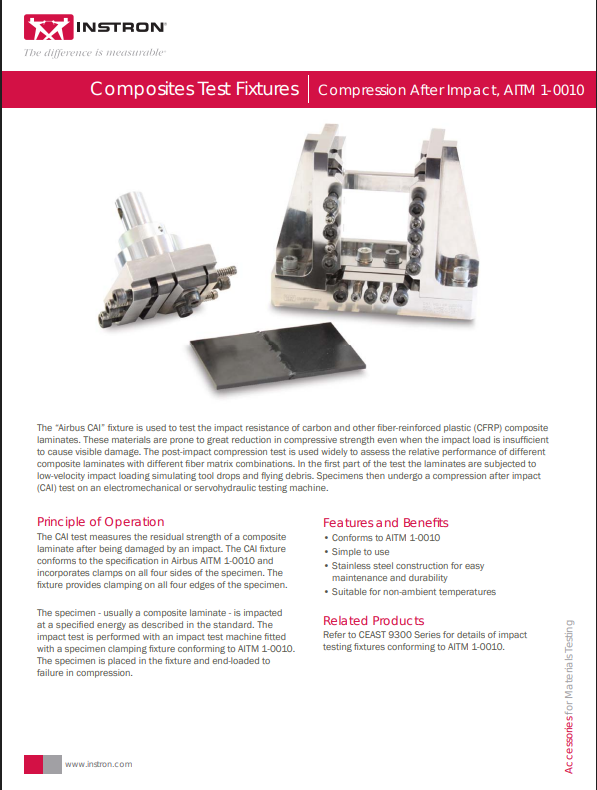

Composites Test Fixture Compression After Impact

The “Airbus CAI” fi xture is used to test the impact resistance of carbon and other fi ber-reinforced plastic (CFRP) composite laminates. These materials are prone to great reduction in compressive strength even when the impact load is insuffi cient to cause visible damage. The post-impact compression test is used widely to assess the relative performance of different composite laminates with different fi ber matrix combinations. In the fi rst part of the test the laminates are subjected to low-velocity impact loading simulating tool drops and fl ying debris. Specimens then undergo a compression after impact(CAI) test on an electromechanical or servohydraulic testing machine.

Compression Platens W-2004 and W-2005 Series

Instron® Industrial Series Compression Platens are designed to maximize compression testing performance. These high-strength, versatile platens are available in both plane and self-aligning models, and can be easily configured with Instron and other static universal testing machines.

Anti-Buckling Compression Testing Fixture

This anti-buckling fixture is designed for compression testing of rigid plastics and the shear testing of reinforced plastics. It has also been adapted for use with high strength composites.

Ball Burst Compression Fixture

Burst or puncture fixtures are used to determine the resistance of a material to the penetration of a probe.

Composite Test Fixtures_Compression After Impact, ASTM D 7137 / D 7137M

The “Boeing CAI” fixture is used to test the impact resistance of carbon and other fiber-reinforced polymer composite laminates. These materials are prone to great reduction in compressive strength, even when the impact load is insufficient to cause visible damage. The post-impact compression test is used to assess the relative performance of different composite laminates with different fiber matrix combinations. Laminates are subjected to low-velocity impact loading simulating tool drops and flying debris or may be subjected to an out-of-plane static indentation

(ASTM D 6264 / D 6264M). Specimens then undergo a compression after impact (CAI) test on an electromechanical or servohydraulic testing machine.