ASTM D695 Teste de compressão de plásticos rígidos

Uma introdução ao site ASTM D695-15

Escrito por Daniel Caesar

ASTM O D695 é um método de teste usado para determinar as propriedades de compressão de plásticos reforçados e não reforçados. Ele é usado juntamente com seu equivalente padrão de teste de tração, ASTM D638. Juntos, o ASTM D695 e o ASTM D638 avaliam as propriedades fundamentais dos materiais de polímeros que são encontrados em todos os setores e até mesmo em todas as residências do mundo. Para entender completamente a configuração do teste, o procedimento e os requisitos de resultados, é importante analisar a norma completa.

O que esse padrão mede?

ASTM A D695 obtém as propriedades de resistência à compressão de um material resistência à compressão de um material, ponto de escoamento compressivoe módulo. O corpo de prova padrão para a determinação da resistência é um cilindro ou prisma reto cujo comprimento é o dobro da largura ou do diâmetro principal. Se o corpo de prova for muito fino, um gabarito de suporte antiflexão deve ser usado para evitar que o corpo de prova se curve.

Sistema de teste de materiais

Dependendo das forças máximas esperadas, o ASTM D695 pode ser realizado em uma máquina de teste universal de coluna única ou de coluna dupla, como as disponíveis no Instron's 3400 e 6800 da Instron.

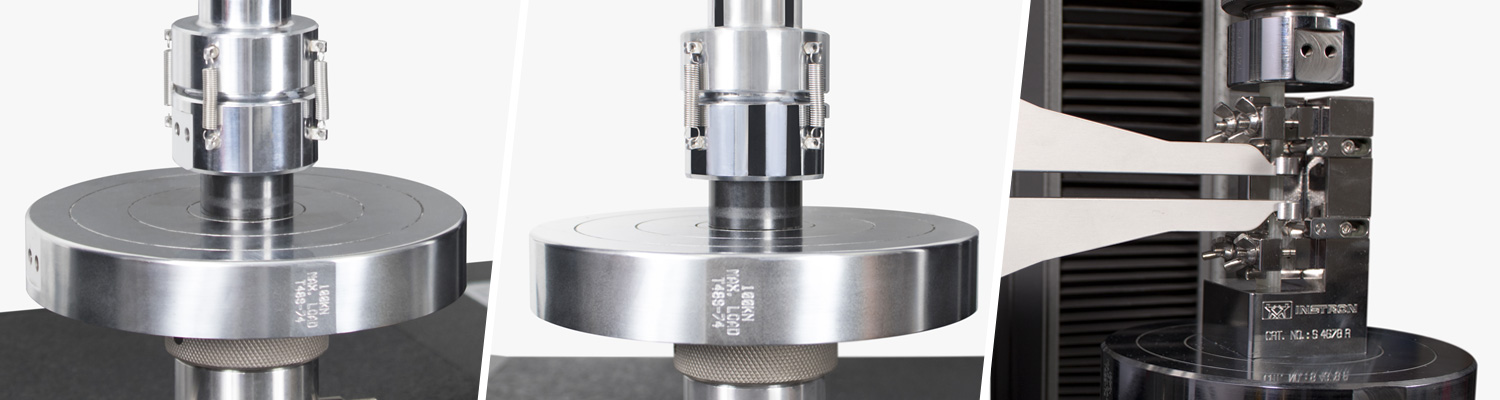

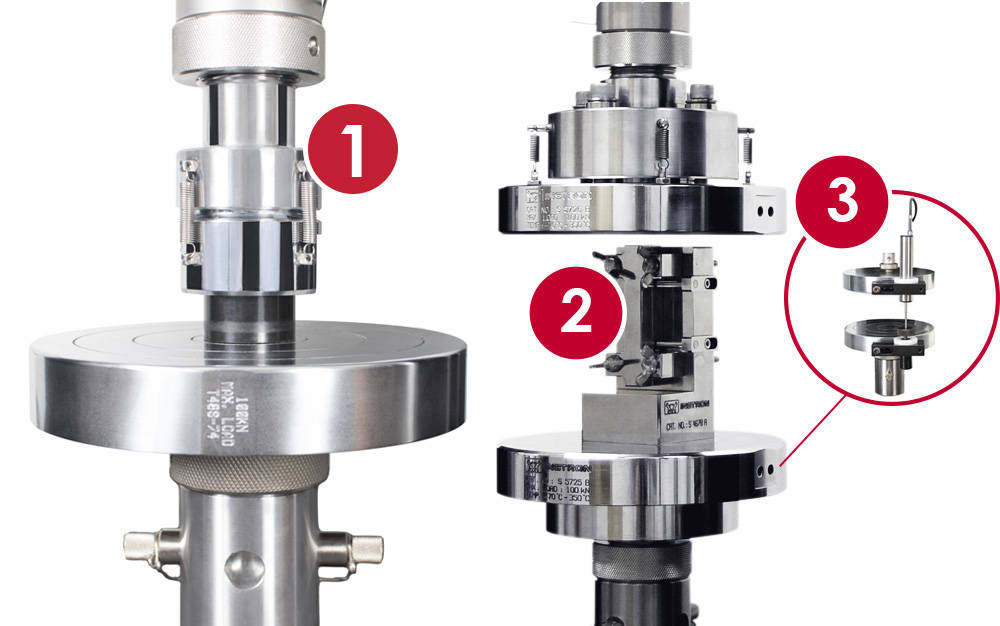

Placas e acessórios

Dependendo da sua aplicação, os seguintes acessórios são comumente usados para o teste ASTM D695:

- Placa de compressão superior com sede esférica integral (os diâmetros variam de 2 “a 8”)

- placa rígida inferior de tamanho correspondente

- 2601-04X série LVDT (transdutor de deslocamento linear)

- Montagem do LVDT para placas (2601-071)

Além da verificação típica ASTM E4 para garantir dados de força precisos, a D695 também exige um extensômetro ASTM E83 Classe B-2 para medir a deformação compressiva. Uma solução de deformação popular é o extensômetro da Instron transdutor de deslocamento linear. Uma solução de deformação mais avançada inclui um extensômetro sem contato, como o Advanced Video Extensometer 2 (AVE 2) da Instron. O AVE2 é ideal para laboratórios com sistemas de teste limitados que precisam realizar uma ampla variedade de testes.

| ASTM Acessórios D695 | |

|---|---|

Sede esférica autoalinhável |

|

Gabarito de suporte anti-flambagem |

|

Série 2601-04x LVDT |

|

Dicas e truques úteis

- As placas de compressão com assentos esféricos integrais são ideais para garantir o paralelismo de placa a placa, que é um requisito da norma.

- Se o corpo de prova for muito fino, deve-se usar um gabarito de suporte antiflexão para evitar que o corpo de prova se curve.

- Se estiver relatando o cálculo do módulo, verifique se o extensômetro e a célula de carga foram verificados na faixa em que o cálculo está sendo feito. Às vezes, os laboratórios informam, sem saber, cálculos fora da faixa verificada de seus dispositivos.

- ASTM O D695 está incluído no conjunto de métodos de teste de plásticos disponível em Bluehill Universal.

- Se a medição direta da deformação e a conformidade com ASTM E83 Classe B-2 não forem necessárias, a correção da conformidade deverá ser usada para remover a conformidade do sistema dos dados de deslocamento da cruzeta. Consulte o whitepaper sobre correção de conformidade para obter mais detalhes.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

Brochura do Bluehill Universal

O Bluehill Universal é o software de teste de materiais avançado da Instron, projetado para interação tátil intuitiva e fluxos de trabalho simplificados. Ele oferece métodos de teste pré-carregados, QuickTest para configuração rápida, exportação de dados aprimorada e Instron Connect para comunicação direta com o serviço. Os usuários do Bluehill 2 e do Bluehill 3 podem atualizar facilmente para a versão mais recente para melhor desempenho e usabilidade

Série 3400 – Soluções de teste acessíveis

Sistemas de teste universal Instron série 3400 para testes de tração, compressão, curvatura e outros testes de propriedades de materiais.

Anti-Buckling Compression Testing Fixture

This anti-buckling fixture is designed for compression testing of rigid plastics and the shear testing of reinforced plastics. It has also been adapted for use with high strength composites.

AverEdge32 Averaged Transverse Strain Measurement

AverEdge32 is an optional advanced feature of Instron’s AVE3 non-contacting extensometer. Standard extensometers with a single local transverse strain measurement can exhibit stepped changes in transverse strain data, making it challenging to obtain an accurate value. AverEdge32 measures transverse strain at multiple locations along the specimen edges and averages them to produce a smooth and repeatable value, which is essential when calculating the r-value of sheet metal.

2501 Series Compression Platens

These easy-to-install compression platens are precisely machined fixtures that are designed for even distribution of compression loads during a test.

2601 Series LVDT Deflection Sensors

The 2601 Series Linear Variable Differential Transformer (LVDT) displacement transducers are measuring devices that measure the displacement of the load frames.