ASTM E190, AWS B4.0 Geführter Biegetest von Schweißnähten

ASTM E190 describes requirements for guided bend testing of welded materials. The guided bend test on welds is designed primarily for metal plates and pipes and provides a quality control check that helps determine the ductility of the weld and the effectiveness of the welding process. During the bend test, the material containing the weld is supported on both ends by the test fixture, while a load is applied at its center point.

Materials Testing System

For ASTM E290 testing we recommend using an Industrial Series DX or HDX model with Bluehill Universal software and a W-6810 test fixture. This fixture allows for adjustment of the support span and is supplied with various sizes of loading mandrels to accommodate different specimen thicknesses. The loading supports are held together with two tie rods to provide extra stiffness during loading. The DX or HDX Model dual test space load frames allow the bend test fixture to be positioned in the lower compression test space. Any tensile testing can also be accomplished in the upper tensile test space.

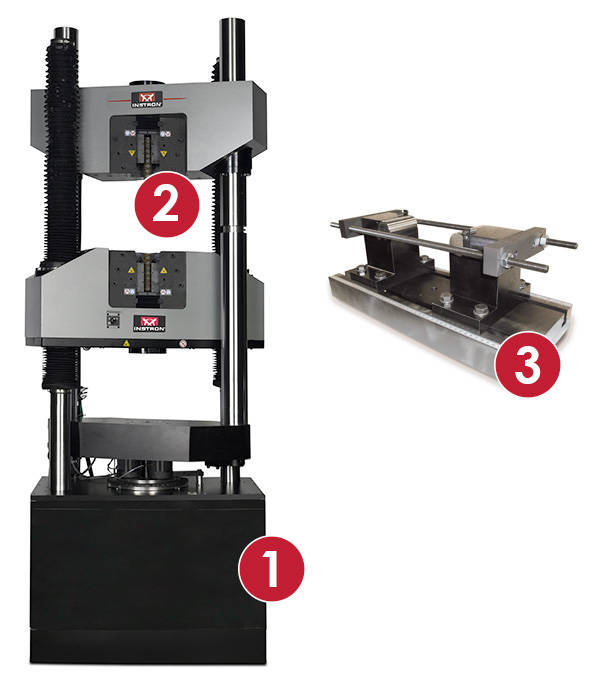

| ASTM E190 Test Setup | |

|---|---|

| 1) | Instron 1000 HDX |

| 2) | W-5340 Hydraulic Wedge Grips |

| 3) | W-6810 test fixture |

Testing Tips and Tricks

This standard is very focused on the interpretation of the tested specimen. Bluehill Universal can easily be configured with a prompted test that allows the operator to note the condition of the tested specimen and report any cracks that are outlined by the code requirements. Digital calipers can also be interfaced directly to the software for quick, push-button input of crack measurements.