Metal Bolt Testing

In the manufacture of automobiles, metallic bolts are used in large volumes ranging in application from high strength required for structural assembly to securing lightweight parts to the vehicle. Whatever the application they are used for, testing is critical to determine if they will be suitable for the application and/or to ensure they are meeting the quality standard.

Quality Control for High Volume Production

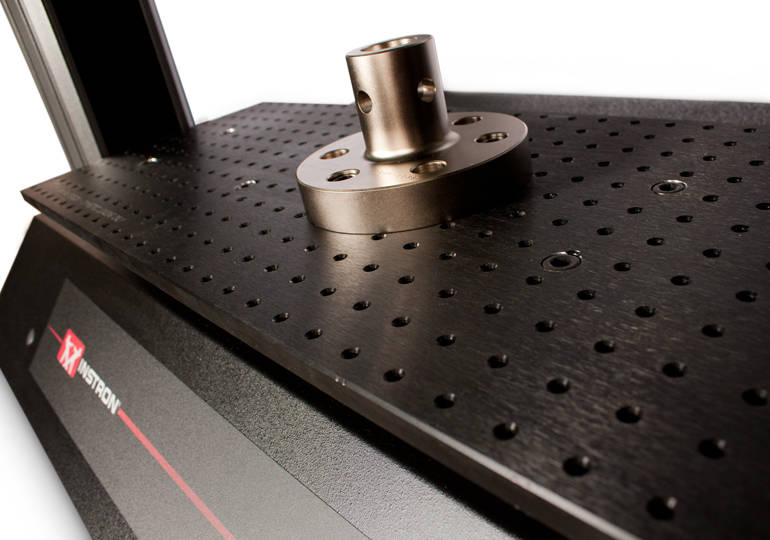

Short Bolt Lengths

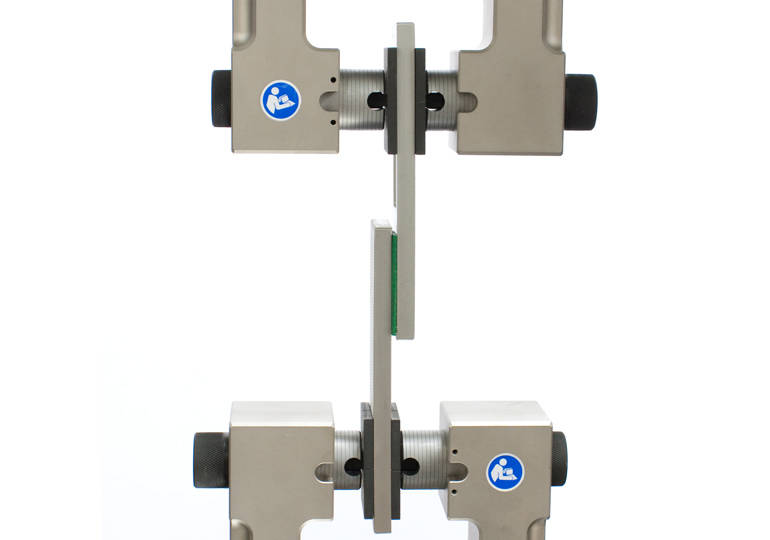

Measuring Strain and Multi Step Loading

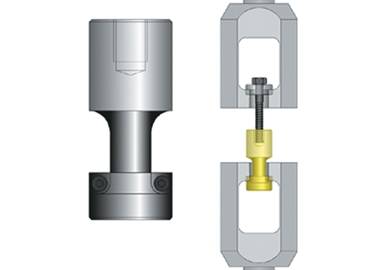

Shear Strength

Learn more about our automotive solutions