ASTM D256 Impact Strength of 3D Printing Peek

Pendulum Test According to ASTM D256

Written by Francesca Pinto

ASTM D256 is a common pendulum impact testing standard for determining the impact resistance and the notch sensitivity in plastics.

In Test Methods A, C and D, the notch produces a stress concentration that increases the probability of a brittle, rather than a ductile, fracture.

What are the main drawbacks of 3D printing PEEK?

There are many factors to consider in 3D printing: there can be a wide variance of mechanical properties including impact strength (after annealing).

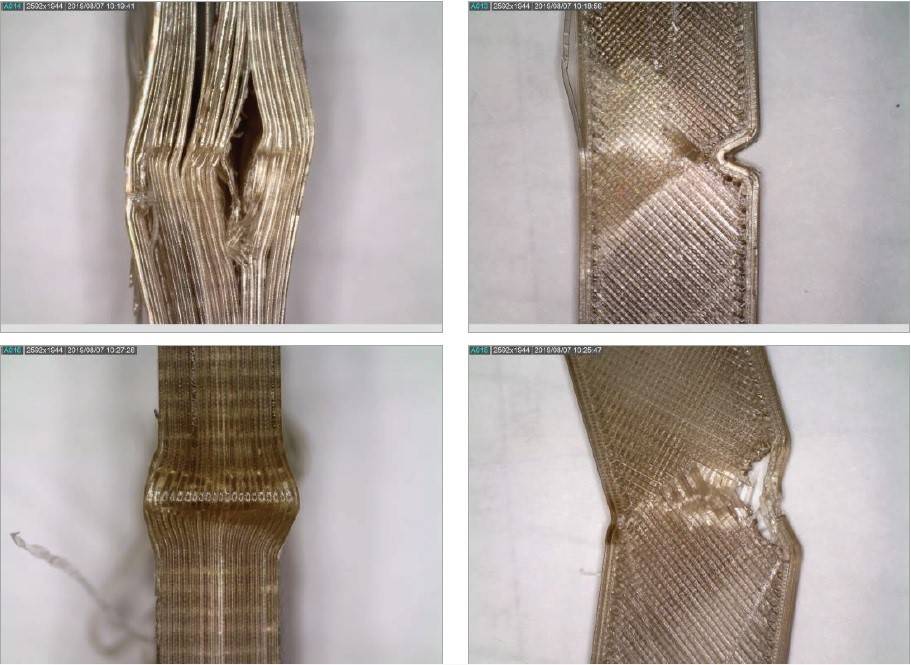

3D printing PEEK presents an apparent thermal deformation during the printing process and the layer bonding is not as good as other 3D printing plastics.

There are few researches about the impact strength evaluation aimed to understand the ability of the material to withstand against impact load. Extensive testing and heat treatment process deserve further studies to confirm the properties of the material and ensure that print parts are optimized.