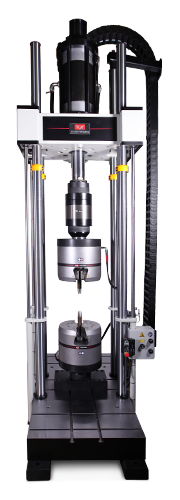

High Capacity Fatigue Testing Systems

Servohydraulic Fatigue Series up to 5000kN

Instron high capacity systems are servohydraulic fatigue testing systems that perform high force static and dynamic tests on specimens up to 5000 kN. These machines use the same software, electronics, and interfaces as all of our general hydraulic fatigue machines, which ensures continuity and consistent experience across machines in your laboratory. Instron will also provide support from dedicated project engineers to design and manufacture high capacity machines and accessories to meet your needs.

The challenges involved with purchasing and installing a machine of this size are very different from those of a more common, lower load capacity fatigue machine. We have an expert team of experienced project engineers who will support you from the initial configuration process through to the final installation and acceptance testing.

8803

|

8805

|

8806

|

8808

|

||

Dynamic Load Capacity |

kN kip |

±500 ±110 |

±1,000 ±220 |

±2,500 ±560 |

±5,000 ±1,100 |

| Actuator Stroke | mm in |

250 9.8 |

250 9.8 |

250 9.8 |

250 9.8 |

| No. of Columns | 2 | 4 | 4 | 4 | |

| Actuator Position | Lower base or Upper Crosshead |

Upper Crosshead | Upper Crosshead | Upper Crosshead | |

| Frame Stiffness | kN/mm | 1,066 | 2,102 | 4,200 | - |

| Maximum Frame Weight | kg lb |

2,450 5,396 |

6,500 14,300 |

16,000 35,300 |

- - |

| Literature | LEARN MORE | LEARN MORE | LEARN MORE | LEARN MORE |

- Choice of hydraulic configuration and dynamic performance to suit the application

- A t-slot base for added versatility and component testing, optional table sizes available to suit the application

- Adjustable upper crosshead with hydraulic lifts and lock fitted as standard for easy adjustment of daylight

Stiffness Based Tuning

Quicker and more accessible tuning

method with no-precycling

Dynacell™ Load Cell

Patented Dynacell advanced load cell technology

for faster testing and reduction of inertial errors

- High-stiffness, precision aligned load frames

- Hydro static bearing actuators for

higher side-load resistance

- Designed for both dynamic and static testing

on a variety of materials and components - Compatible with a wide range of accessories

including grips, fixtures, and chambers

Controllers and Software

These machines are supplied with Instron’s latest 8800MT digital controller, providing full system control including patented stiffness based tuning, amplitude control, specimen protect, adaptive control technology, 19 bit resolution across the full range of transducers, and up to 10kHz synchronous data acquisition across all channels.They also allow access to WaveMatrix™3 Dynamic Testing Software, Bluehill® Universal Software for quasi-static tests, and other application specific software such as Bluehill Fracture for pre-cracking and crack growth studies, or LCF3 for Low Cycle Fatigue testing.