Power Packs and Accessories

Challenge

High-quality hydraulic power supply units are required to supply hydraulic oil to servohydraulic linear and rotary actuators, testing machines and test systems. Due to the use of servovalves, care must be taken to ensure the highest purity of the pressure oil in order to ensure a long service life of the valves. At the high pressures and oil velocities that occur in a servohydraulic system, even the smallest dirt particles at the control edges of the servo valve are highly erosive.

Since the units often operate continuously around the clock, maintenance requirements and the ease of service are key considerations. In addition, modern hydraulic units have to meet high standards with regard to laboratory safety, energy consumption and environmental compatibility.

Solution

Instron hydraulic power supply units (HPUs) are the result of many years of experience in the field of high-pressure hydraulics.

Instron offers 6 standardized hydraulic units with nominal flow rates between 26 l / min. Up to 365 l / min at operating pressure 280 bar (other operating pressures, e.g.: 210 bar are also possible).

The power packs can be coupled to one another in order to enable larger flow rates, resulting in a large shared reservoir. The respective motors and pumps can be individually switched in order to ensure economical operation.

Class A efficiency motors combined with variable flow pumps provide the best possible energy efficiency whilst the standard 280 Bar operating pressure provides further efficiency benefits in comparison to 210 bar systems.

All the key components have been designed to minimize service requirements and are easily accessable for inspection and preventative maintenance. The optional pump management system ensures service hours of multiple pumps are balanced to further optimize maintenance times and costs.

For centralized hydraulic facilities, Instron offers tailor-made solutions to suit the specific needs of the laboratory. In this case, central tanks can be used and the size and number of motor-pump units can be optimized for efficiency.

The essential features of the Instron hydraulic power packs are as follows:

- Low energy consumption thanks to infinitely variable flow control.

- Constant operating pressure (adjustable up to 290 bar).

- Pressure line filtration of the oil

- Robust and self-priming pump in 9-piston axial piston design

- Extremely low volumetric pulsation

- free from cavitation effects

- Very smooth running due to multiple vibration insulation

- Connection-ready with complete control electronics

- Oil cooling with water (optionally with air)

- Operation direct and/or via remote control

- Designed for minimal maintenance and ease of service

In addition to test systems operating with a defined and fixed number of actuators, a high degree of flexibility is required for the testing of components with regard to expansion, interchangeability or modification of the test set-up. In order to meet these requirements, Instron has developed the concept of modularly configurable function blocks. The function blocks consist of different functional units which are combined as required to perform the following tasks:

- Switch the hydraulic power on and off

- Pre-filling with low flow and low pressure in setup mode

- Pressure increase to nominal pressure

- Save energy and targeted delivery as needed

- Reduced and limited working pressure and flow

- Pressure relief

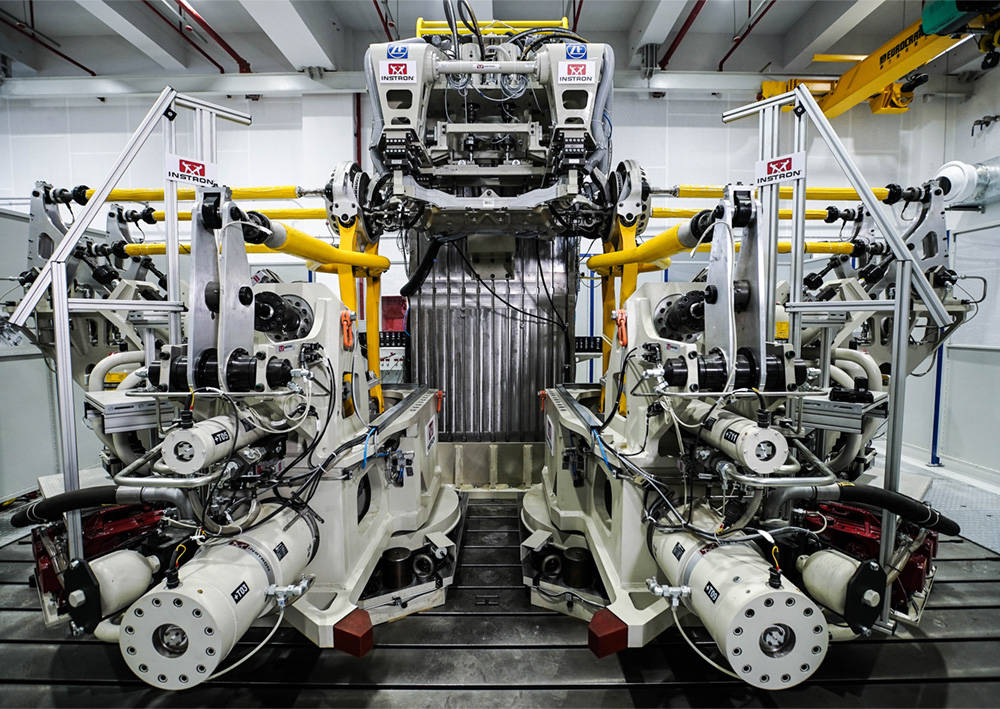

Axle Test System

Axle test rigs are used to reproduce different loads applied to the axle elements when a vehicle is traveling over a variety of road surfaces. Instron can provide models for testing of car, van, truck and bus axles with 6 degree-of-freedom.

Saber maisComponent Test Systems

Instrons component testing systems are characterized by the highest quality and reliability, ensuring the highest productivity in daily use.

Saber maisMulti-Axis Shaking Table (MAST)

Multi-axis simulation (MAST) tables are designed for testing of a variety of different specimens in six degrees of freedom. These include components and subassemblies exposed to vibratory loads during vehicle operation; from seats, dashboards and interior equipment components to engine mounts, and cooling modules.

Saber maisRoad Simulator

HYDROPULS® road simulators are a versatile and cost efficient solution for testing load inputs through the tires. They are used to perform durability tests, as well as acoustic and vibration analyses in testing and development (BSR, NVH) on complete vehicles, subsystems and power train assemblies.

Saber maisFull Vehicle Test System

Instron offers comprehensive solutions with and without vehicle restraint, with long- or short-stroke introduction of lateral forces as well as the optional environmental simulation with regard to temperature humidity and sun loading.

Saber maisDynamic Torsion Test System

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed.

Saber maisShock Absorber Test Systems

Instron's MSP test system is the ideal tool for reliable, fast and realistic tuning of vehicle chassis designs and development of shock absorber systems.

Saber mais