Chassis and Body High Strain Rate Testing

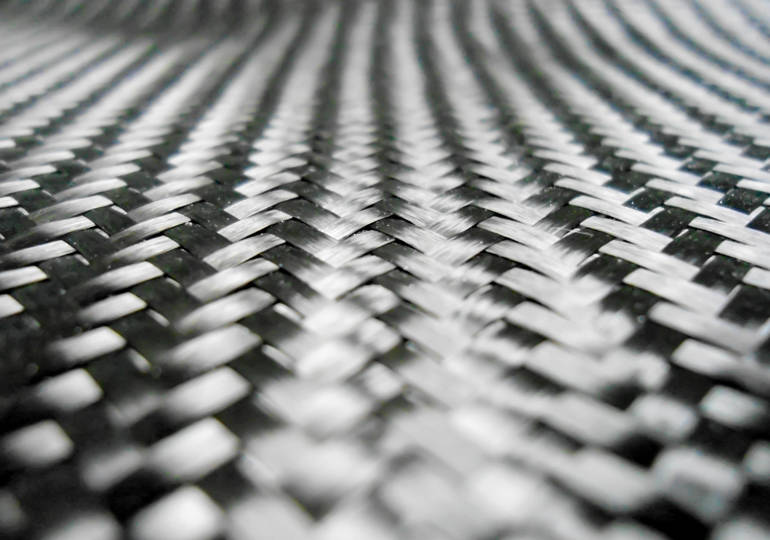

In the automotive sector, development in chassis and body of vehicles is driven by two main aspects, safety, and lightweighting. As the body is the first point of impact during a car crash, modern designs have incorporated features such as crumple zone to absorb most of the initial impact, reducing the force that will reach the passengers. With this in mind, it is essential to understand material behavior under high strain rate, especially during development cycles of metals, alloys, and composites that may be used in chassis or body design. On the other hand, lightweighting provides better fuel economy for the car, decreases component wear and hence provide a much more competitive product overall. Therefore, characterizing how material properties change under high strain rate is important in order to find the optimum design maximizing safety and lightweighting.

Sheet Metal High Strain Rate Testing

The Challenge

When considering the crashworthiness of components, testing in high strain rates is essential. As investigated by numerous research, mechanical properties of materials differ drastically under quasi-static conditions and high strain rates. Therefore, accurate data on strain rate dependence of material behavior will provide more realistic computer simulation and evaluation of crashworthiness of structures, whether it is during the development of new alloys or testing automotive components.

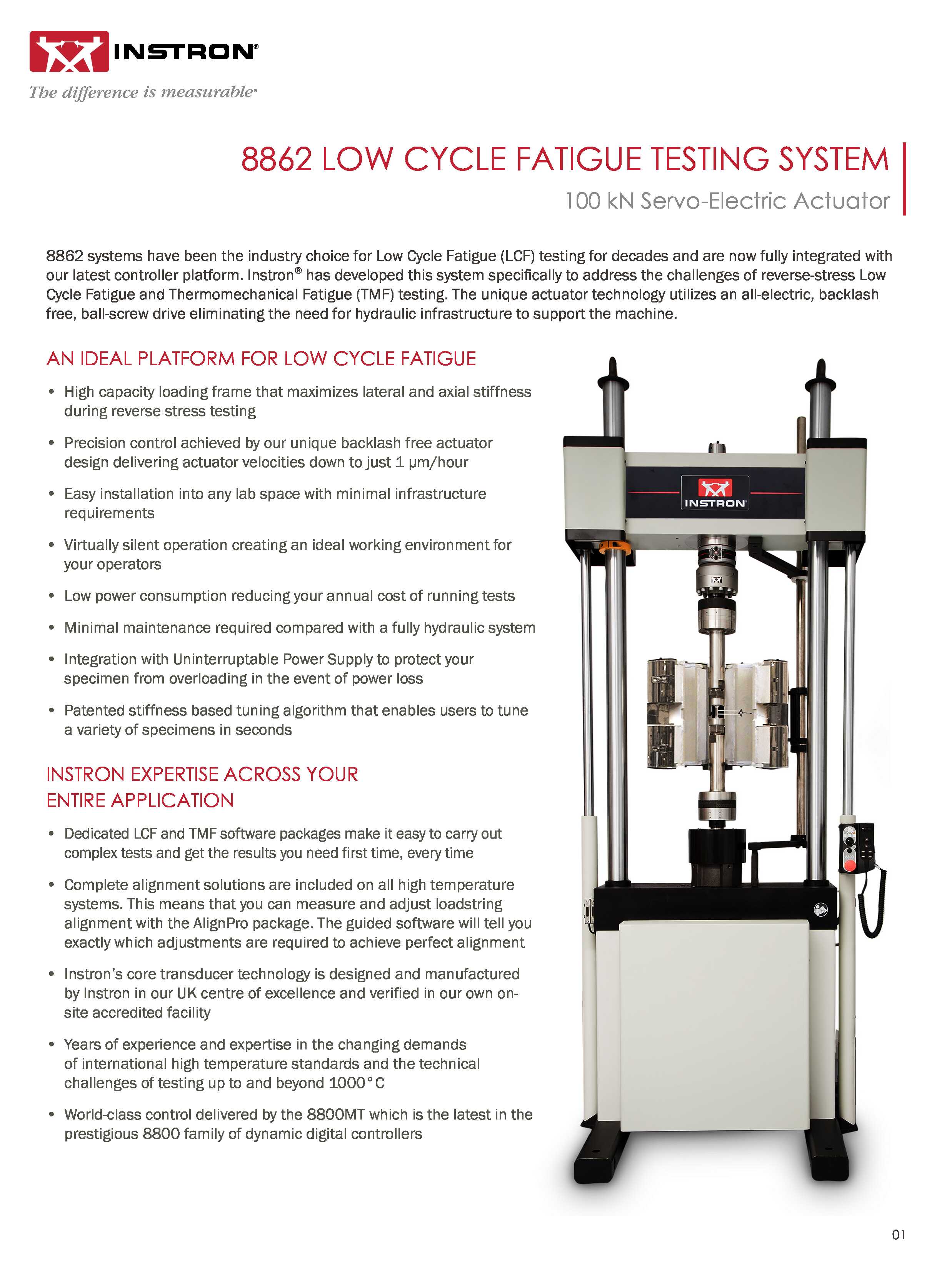

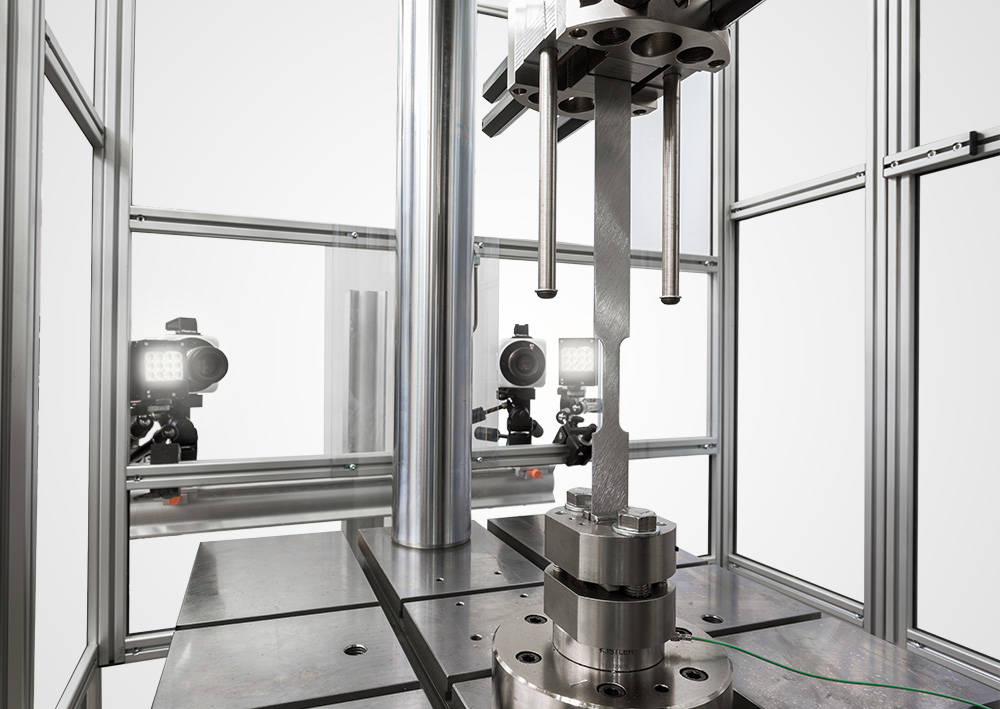

Our Solution

To meet the challenges of high strain rate testing, Instron has been the market leader in manufacturing high strain rate testing machines for over 20 years, advancing high strain rate research and testing capabilities on metals with suitable technologies. For testing metals and high-performance alloys, Instron offers a range of VHS systems that can perform tests that will be suited to your application up to a maximum test velocity of 25 m/s, which translates to testing conditions from quasi-static up to a strain rate of 1000/s. Instron also offers fast jaw or slack rod tensile gripping solutions to ensure gripping at test velocity and DIC integration that will provide non-contact strain measurement with the capacity for dedicated strain gauge channels.