THE CHALLENGE

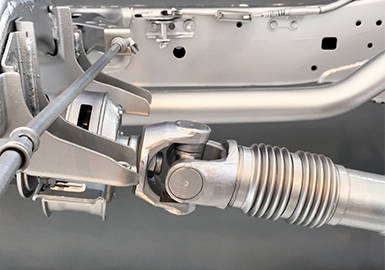

Under driving conditions, drive shafts are exposed to a full range of service loads. To ensure optimum transmission of the torque from the gearbox or differential to the wheels, drive shafts must compensate for the suspension geometry and wheel accelerations whilst ensuring perfect synchronism between the joints at all times. To test the durability of drive shafts, dynamic torques have to be introduced over the full range of movement and under various environmental conditions.