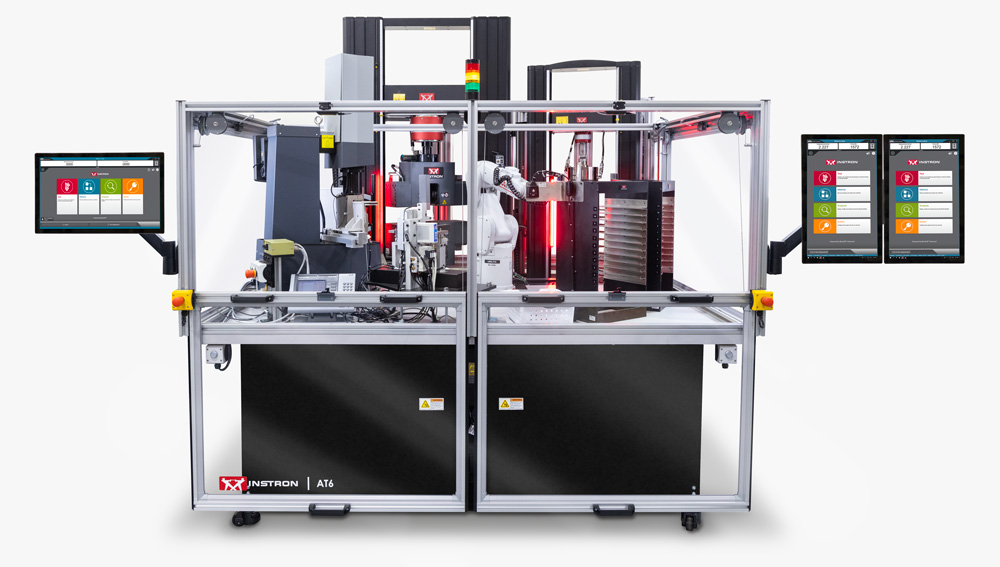

AT6

6 Axis Robotic Automated Testing System

The Instron AT6 is a modular, 6-axis robotic system that automates tensile, flexural, compression, and lap shear testing to ASTM and ISO standards. Supporting forces up to 600 kN and a wide range of materials, it enables fully unattended testing of up to 500 specimens. With configurable stations, optional temperature chambers and parallel test frames, the AT6 maximizes throughput and integrates seamlessly with other lab equipment for high-efficiency, high-volume environments.

TAILORED TO YOUR TESTING NEEDS

Modular by Design, Built for Flexibility

Customize the AT6 to match your exact testing requirements with a wide range of modular options, including:

- Floor-standing, tabletop, or single-column universal testing machines

- Pneumatic or hydraulic grips for diverse material handling

- Axial and transverse strain measurement via video or contact extensometry

- Specialized end effectors and specimen racks for various material types

- Dual-frame configurations to enable parallel testing and boost throughput

- Seamless integration with auxiliary equipment like durometers, hardness testers, and surface roughness testers

BLUEHILL® AUTOMATION SOFTWARE

A Simpler Way to Program Automation

Bluehill Automation is designed to manage the automated sequences and devices of the AT6 system, working seamlessly alongside Bluehill Universal. It enables fully unattended testing across multiple racks and test types, with simplified process sequencing, barcode parsing, and secure data and system management. Supporting multiple methods, geometries, and standards in a single run, it simplifies complex workflows into one streamlined, efficient process.

EFFICIENCY AND PRODUCTIVITY

Boost Throughput with Advanced Automation

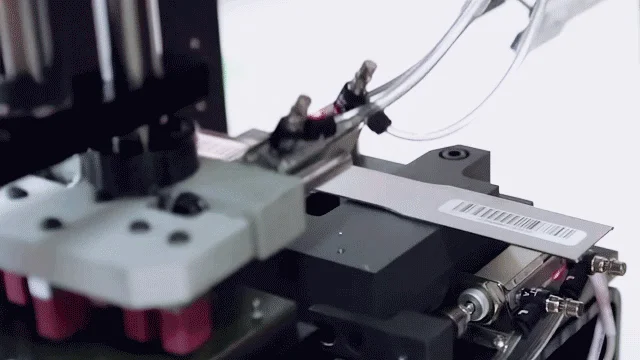

Robotic Arm

The Mitsubishi 6-axis robot handles specimen movements, loading, and unloading - freeing up operators to focus on higher-value activities.

Specimen Removal

An enhanced removal mechanism increases throughput by extracting tested specimens while the next is being prepared, minimizing downtime between tests.

Dual Frame Configuration

A single robot can serve multiple testing frames simultaneously, enabling parallel testing and significantly accelerating overall throughput.

SAFETY AND ERGONOMICS

The AT6 system is fully enclosed to isolate operators from the testing area, eliminating exposure to pinch hazards and repetitive motions common in high-volume manual testing. This hands-free approach enhances workplace safety and reduces the risk of injury.

Minimizes Repetitive

Motion Injuries

Eliminates Potential

Pinch Hazards

Enables Safe, Automated

Removal of Debris

ACCURACY AND CONSISTENCY

Eliminating Variability from the Testing Process

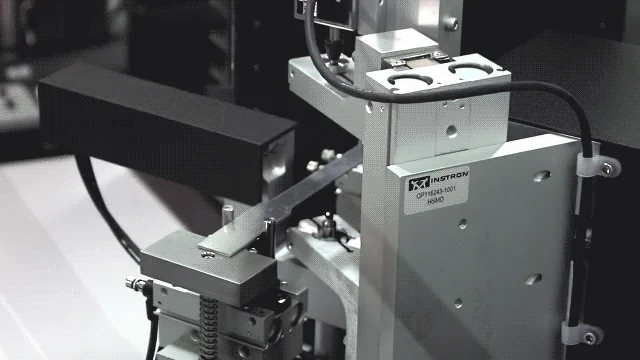

Specimen Measurement

Dual-axis measurement devices capture precise specimen dimensions before each test, ensuring consistent input data.

Specimen Marking

Specimens are marked automatically for accurate tracking by video extensometers, improving strain measurement reliability.

Programmed Technology

Every movement — from loading to disposal — is pre-programmed to replicate the same actions across specimens, enhancing repeatability and reproducibility.

COMMON APPLICATIONS

The AT6 can automate tension, compression, and flexural tests on rigid plastics, elastomers, metals, composites, thin films, and biomedical applications.

AT6 Configured for Plastics, Elastomers, and Thin Film Tensile Testing

AT6 Configured with Environmental Chamber for Non-Ambient Elastomers Testing

AT6 Configured for Metals Tensile and Hardness Testing

AT6 Configured for Suture Tensile Testing

Frequently Asked Questions

The Instron AT6 is designed to support a wide range of ASTM and ISO materials-testing standards. Common configurations comply with:

- ASTM D638 / ISO 527 - Tensile Properties of Plastics

- ASTM D790 / ISO 178 - Flexural Properties of Plastics

- ASTM D412 - Tensile Properties of Rubber and Elastomers

- ASTM D882 - Tensile Properties of Thin Plastic Sheeting

- ASTM E8 - Tensile Testing of Metals

- ISO 6892 - Tensile Testing of Metals

Because the system is fully customizable, Instron engineers can tailor the configuration to meet the exact requirements of your specific material standards. To confirm compatibility with your testing standards, please contact us.