Axial-Torsion 8850 Systems

±100 kN, ±1000 Nm / ±250 kN, ±2000 Nm

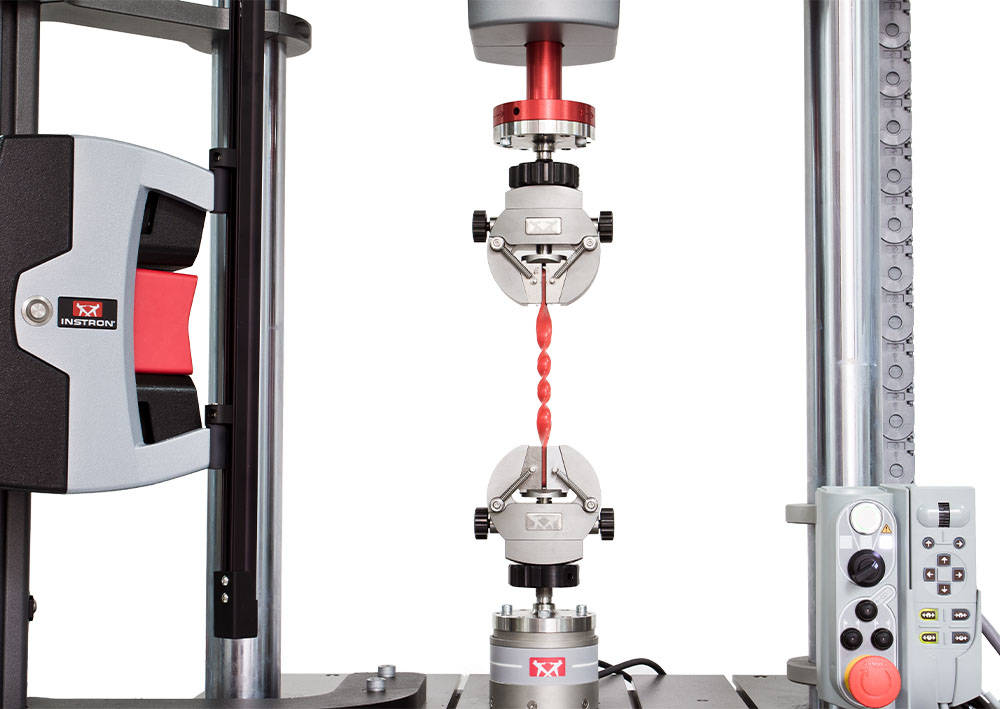

The Instron 8850 series system is a floor model biaxial servohydraulic dynamic test system that provides axial and torsional load on the specimen in an integrated biaxial actuator. With a precision aligned, high-stiffness twin-column frame, the 8850 series meets the challenging demands of a varied range of both static and dynamic biaxial testing requirements. Instron provides a wide range of high capacity axial-torsional accessories and custom options to suit your testing needs. Many components of the frame can be configured to aid convenience and requirements according to your applications. Our dedicated project engineers will assist in every step of the purchasing process from configuring your machine to delivery, installation and system handover. The 8850 series combined with advanced features of a two-axis 8800MT digital controller and an axial-torsional fatigue-rated Dynacell™ enable Instron to supply fully integrated turnkey solutions to meet the most demanding applications.

Our Range

- The Instron 8852 system has an axial load capacity of ±100 kN (±22 kip) and a torque capacity of ±1000 Nm (±8800 in-lb), with an axial actuator stroke of 150 mm (6 in) and a rotary stroke of 90°.

- The Instron 8854 system has an axial load capacity of ±250 kN (±56 kip) and a torque capacity of ±2000 Nm (±17700 in-lb), with an axial actuator stroke of 100 mm (4 in) and a rotary stroke of 90°.

Standard Features

- Axial-Torsion actuator assembly with a decoupled linear-rotary mechanism

- Precision-aligned load frame with induction hardened chrome plated columns and high side load resistance

- Hydraulic lift and locks of the upper crosshead for ease of adjustment of the crosshead

- An actuator in upper crosshead with IGUS chain hose management system to prevent overhanging cables around the machine

- Patented Dynacell™ load cell featuring compensation for inertial loads caused by heavy grips and fixtures in both axes

- Wide range of axial-torsional grips, fixtures, and accessories that will suit your application

- Hydraulic grips with interchangeable wedge and collet heads for flat and round specimen

- Versatile and highly configurable test space with T-Slot table and threaded fixture holes for accessory mounting

- Optional 280 bar seal-less high-performance actuator available as a configuration

- Available with Console, WaveMatrix™3 and Bluehill® Universal for a consistent user experience

Controller and Software

The Instron 8850 series is supplied with a two-axis 8800MT digital controller, which comes with Console software to provide full system control from the PC, including waveform generation in both axes, calibration, limit set up, and status monitoring. The 8800MT controller also enables the use of WaveMatrix3 block loading software for simple and advanced axial-torsion dynamic tests on materials or components, and Bluehill Universal software for static tests.

8850 Series Axial Torsion Systems

The Instron 8850 series system is a floor model biaxial servohydraulic dynamic test system that provides axial and torsional load on a specimen in an integrated biaxial actuator. With a precision aligned, high-stiffness twin-column frame, the 8850 series meets the challenging demands of a varied range of both static and dynamic biaxial testing requirements.

- Products

- 05/28/2019

- 776.7 KB

Axial-Torsion Testing

Axial-torsion testing machines help characterize biaxial mechanical properties of materials, both in static and dynamic conditions, which helps in choosing the right materials for different applications where components are exposed to axial torsion loading profiles.

- Products

- 05/29/2019

- 600.63 KB