Melt Flow Index Testers

Extrusion Plastometers for Rapid Incoming Material Acceptance and Efficient Process Control

Instron® MFi Series of melt flow index testers are specifically designed for easy and accurate measuring of Melt Flow Rate (MFR) and Melt Volume Rate (MVR) according to Melt Flow Rate testing procedure A, procedure B and procedure C determined by ASTM D1238 and ISO 1133 standards.

Why Melt Flow Testing Optimizes Your Productivity

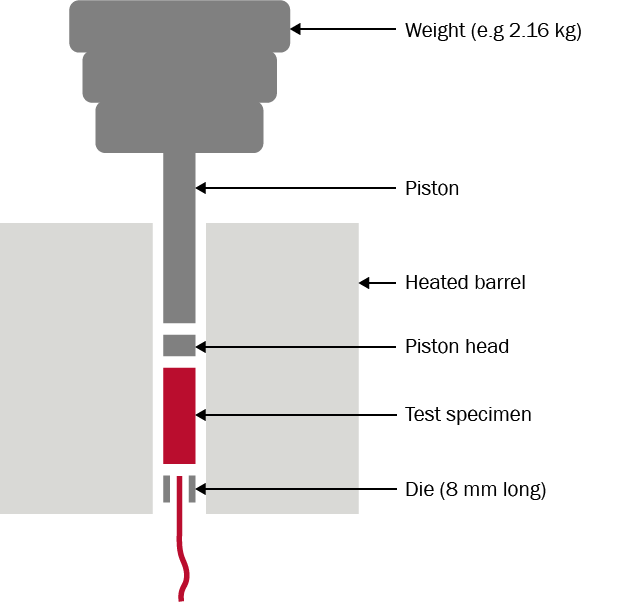

Melt flow testing is simply a measure of the flow of a polymer when melted. The result of a melt flow test, called the melt mass-flow rate (MFR) or melt volume-flow rate (MVR), is defined as the amount of mass or volume of a polymer that flows through a small die at a specified temperature and pressure.

Accelerated expectations for rapid material processing and delivery continue to ride. Avoiding production bottlenecks is a key to secure your profit and gain a competitive advantage in the market. The advanced technology of Instron new Melt Flow Index Testers minimize costly errors and increase your productivity.

Smart User Interface

Create a test method with just 3 inputs and see real time graphs (MFR/MVR vs. individual measurements) and test results

Live Help

Available for each screen it supports you to perform error-free tests while reducing new operators trainings

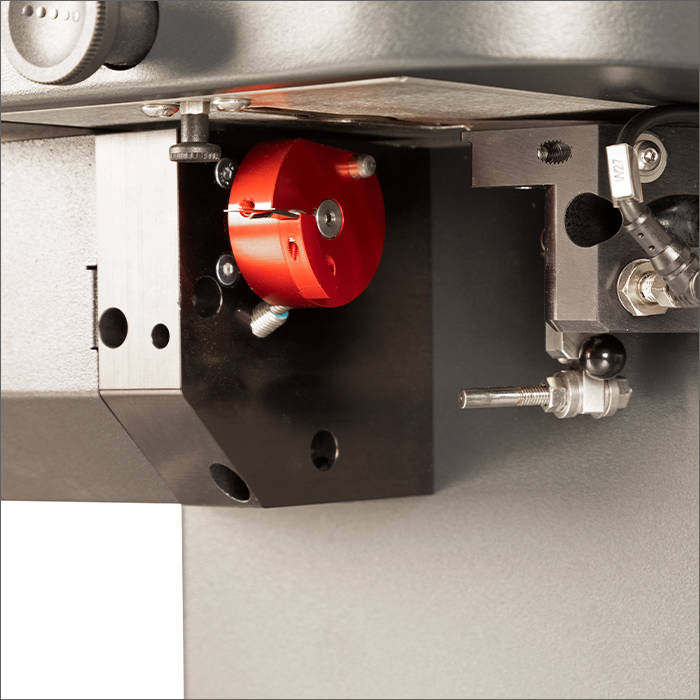

High Flow Solutions

Light piston and automatic die plug opening assist you in selecting the perfect quantity of high-flow resin while reducing materials waste and component maintenance

Bluehill® Melt Software

Avoid unintended interactions when running parallel tests: create and distribute Testing Methods towards several different Instron Melt Flow Testers – Receive and analyze – Centralize print and export LIMS

Self Installation

Save time and costs. Get your MFi ready for testing activities by self installing it with the support of our instruction videos

Which Melt Flow Index Tester is Right for the Growth of your Business

The MFi5 is a compact instrument that allows rapid inspection of the melt mass flow rate of plastics to Procedures A, B, and C.

The MFi7 is a modular instrument for a growing volume of Procedure A, B, and C tests, featuring advantages attributed to automation.

Specifications

|

MFi5

|

MFi7

|

|

| Type of Test | Methods A, B, C | Methods A, B, C |

| Test Temperature Range | 50° – 450° | 50° – 450° |

| Piston Travel Transducer | ✓ | ✓ |

| PTT Resolution | <0.005 mm | <0.005 mm |

| Test Masses Range | 0.100 – 21.6 kg | 0.100 – 21.6 kg |

| Test Masses Motorizied Lifter | - | ✓ |

| Automatic Compacting and Purging | - | ✓ |

| Motorized Melt Cutter | ✓ | ✓ |

| Test Masses Manual Selector | - | Optional |

| Die Plug Automatic Opening | Optional | Optional |

| Temperature Accuracy | <0.3°C | <0.3°C |

| Barrel Type | STANDARD: Nitrided Steel with Superior Wear Resistance | STANDARD: Nitrided Steel with Superior Wear Resistance |

| OPTIONAL: Special stainless-steel for corrosive materials | OPTIONAL: Special stainless-steel for corrosive materials | |

| Temperature Resolution | <0.05°C | <0.05°C |

| User Interface | 7’’ Capacitive touch display | 7’’ Capacitive touch display |

| Other Facilities Required to Operate Basic Machine and Options | Only Electrical supply | Only Electrical supply |

| Additional Safety Shields | - | Optional |

| Bluehill Melt Software | Optional | Optional |

| Export Interfaces | USB, LAN for Bluehill Melt Software | USB, LAN for Bluehill Melt Software |

| Basic Machine Dimensions (w × d × h) | 510 x 370 x 600 mm | 510 x 370 x 850 mm |

| Machine Dimensions with Options (w × d × h) | 510 x 370 x 700 mm | 775 x 440 x 1200 mm |

| Basic Machine Mass | 60 kg | 70 kg |

| Power Supply | 660 W | 780 W |

| Electrical Supply Only | 230 or 115 V UL/CSA ready 50/60 Hz |

230 or 115 V UL/CSA ready 50/60 Hz |

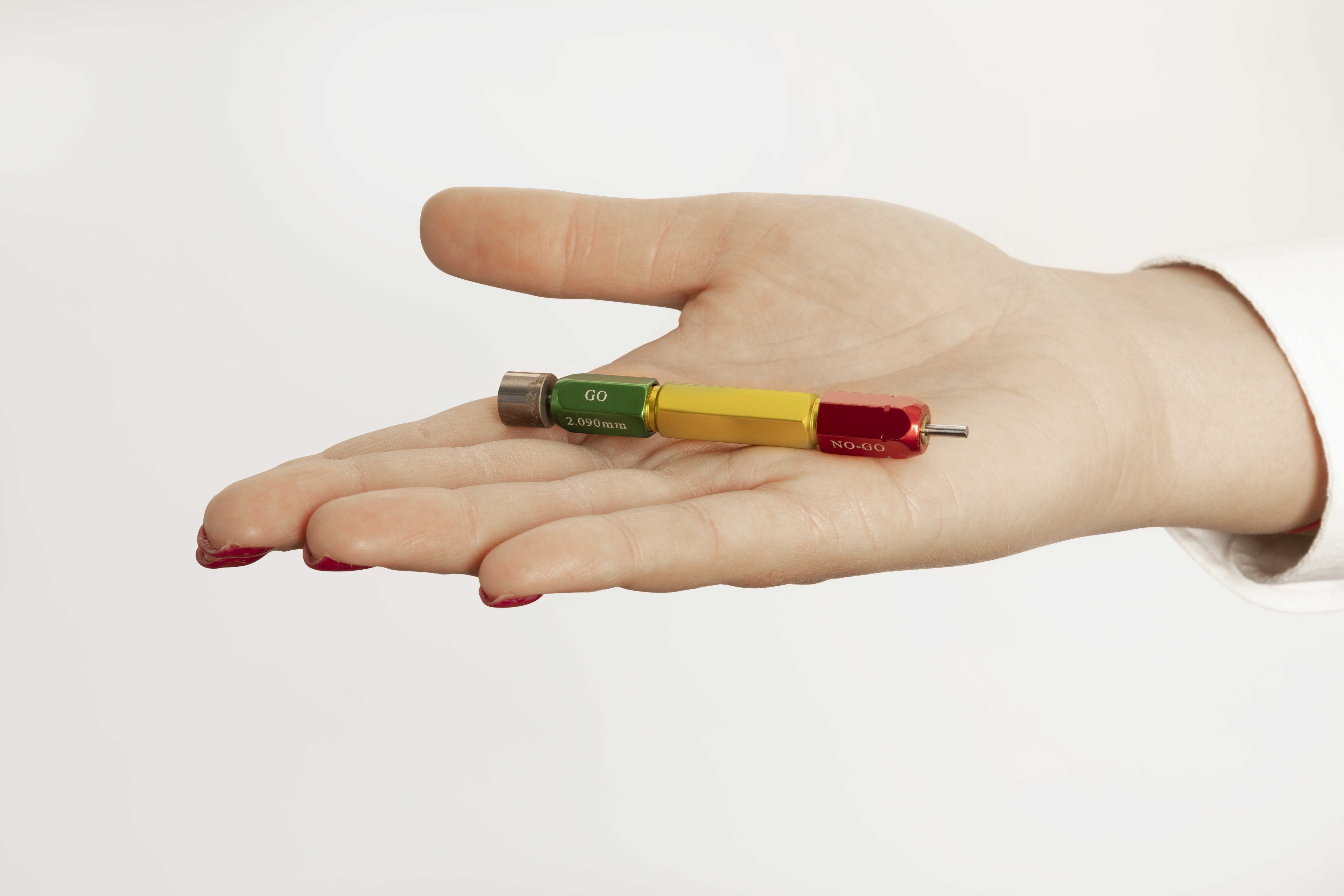

Melt Flow Index Tester Maintenance: Top Tips to Optimize your Test Repeatability and Accuracy

A melt flow index tester requires regular maintenance to deliver repeatable and accurate results over time. Here we look at four maintenance top tips to maximize an Instron melt flow tester’s uptime and efficiency.