CEAST: Compagnia Europea Apparecchi Scientifici Torino (CEAST)

CEAST stands for Compagnia Europea Apparecchi Scientifici, Torino. This is an Italian phrase meaning a European Scientific Instruments Company located in Torino.

From the acronym, you may have guessed that CEAST was founded in Italy. However, today it is no longer just a European company. CEAST was acquired by Illinois Tool Works (ITW) in 2008 and has been positioned under its Test & Measurement Group’s Instron Division.

Today the CEAST product lines are sold around the world through Instron's sales & service team as well as a local agencies.

The company was originally founded in 1953 by Dr. Mario Grosso. CEAST supplied instruments for the Italian Petrochemical Industry that had been destroyed by the World War II. CEAST starting then to develop instruments for polymers characterization, research and quality control, collaborating with Dr. Giulio Natta (Nobel Prize winner for the first synthesis of Polypropylene). CEAST was known for supplying advanced testing equipment for mechanical, physical and rheological characterization of all polymer types with the first Melt Flow instrument in 1960.

Today, CEAST products are still designed and manufactured in Italy.

9400 Series Drop Tower Brochure

Instron Drop Towers are used to develop, fine tune, and validate material models. Testing materials under real impact conditions is a crucial step prior of product design. Using the characterization data obtained with the Instron 9400, coupled with customer supplied high-speed video, you can have confidence in your results and deliver new materials to your customers faster. Our Drop Tower impact systems, fixtures, and tups are designed to meet a wide range of applications and testing standards including: ISO, ASTM, ANSI, Airbus, Boeing, BSI, DIN, EN, FDA, Ford, GM, JIS, NASA, GOST, and more.

9000 Series Pendulum Impact Testers POD

The Instron 9000 Series of pendulum impact testers are designed for determining the impact resilience of thermoplastics. Available in capacities from 0,5 to 50 Joules, the 9050 models are reliable and easy to operate.

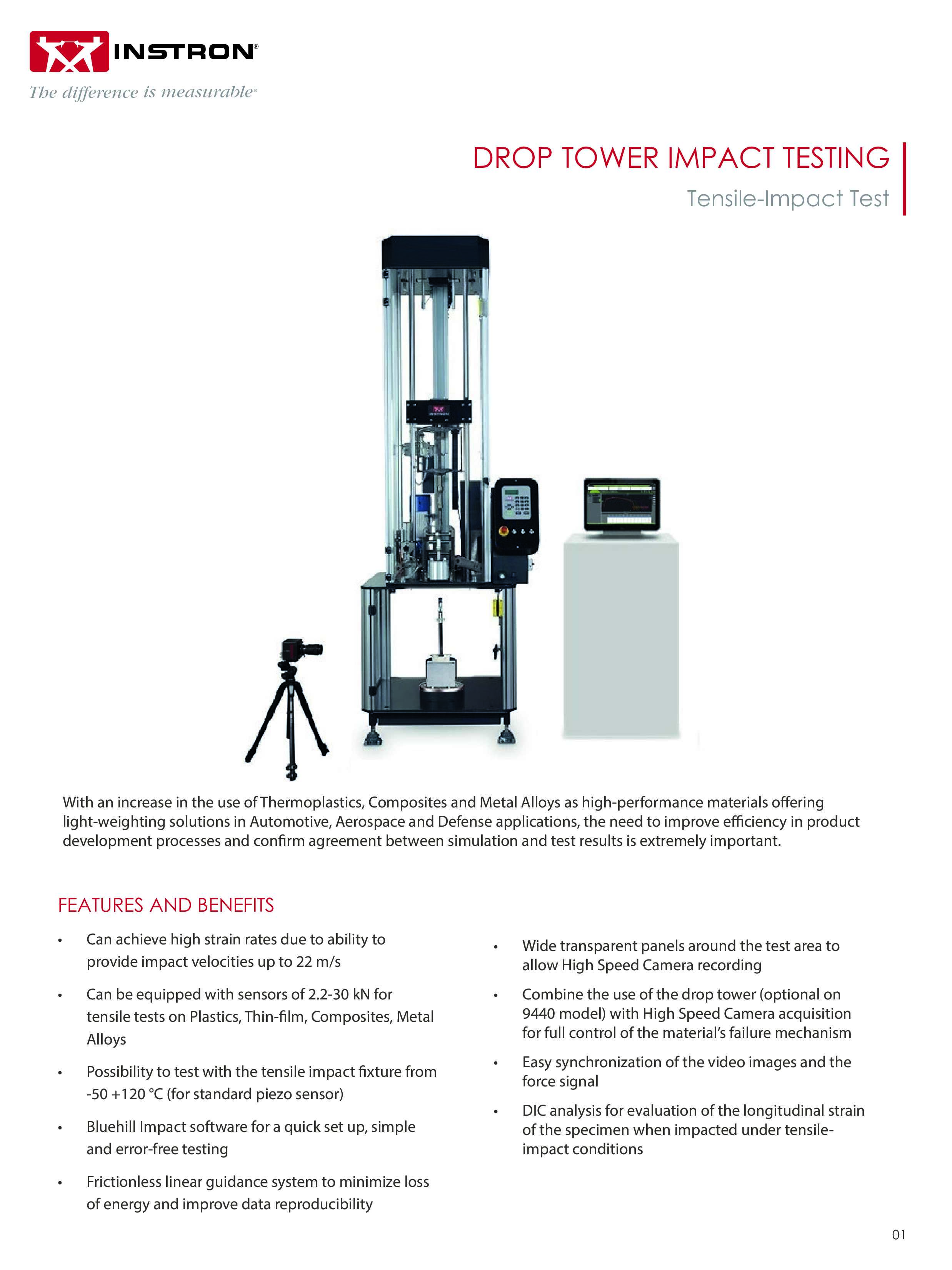

Drop Tower Tensile Impact Testing

With an increase in the use of Thermoplastics, Composites and Metal Alloys as high-performance materials offering light-weighting solutions in Automotive, Aerospace and Defense applications, the need to improve efficiency in product development processes and confirm agreement between simulation and test results is extremely important.

Motorized Impact Testing System (MPX)

The Instron® MPX Series of motorized pendulum impact testers are preferred for metals impact testing to Charpy and Izod standards.

Impact Drop Tower – Three-Point Bending

The mechanical properties of plastic materials are sensitive to loading rate and the fracture toughness under dynamic loading has received considerable attention because it often concerns the failure of structural materials during their service life.