Yield Point

The yield point of a material is a mechanical property commonly measured during materials testing. The yield point of a material occurs when the material transitions from elastic behavior - where removing the applied load will return the material to its original shape - to plastic behavior, where deformation is permanent. On a stress/strain curve, the elastic region is generally depicted as the portion of the curve with a constant slope.

Yield can be measured in several different ways depending on the type of material and type of test being performed (tension, compression, etc). The most important results from measuring yield are yield strength and yield strain, as these values are often used to evaluate whether or not a material is appropriate for a certain application. Yield strength is particularly important, since it is needed to determine if a material meets a required Factor of Safety (FoS). For example, if an engineer is sourcing a material to be used for elevator cables, it is standard to require a FoS of at least 10, which ensures that the cable is guaranteed to withstand ten times the maximum applied stress. The FoS is determined by dividing the yield strength by effective maximum applied stress of the cable.

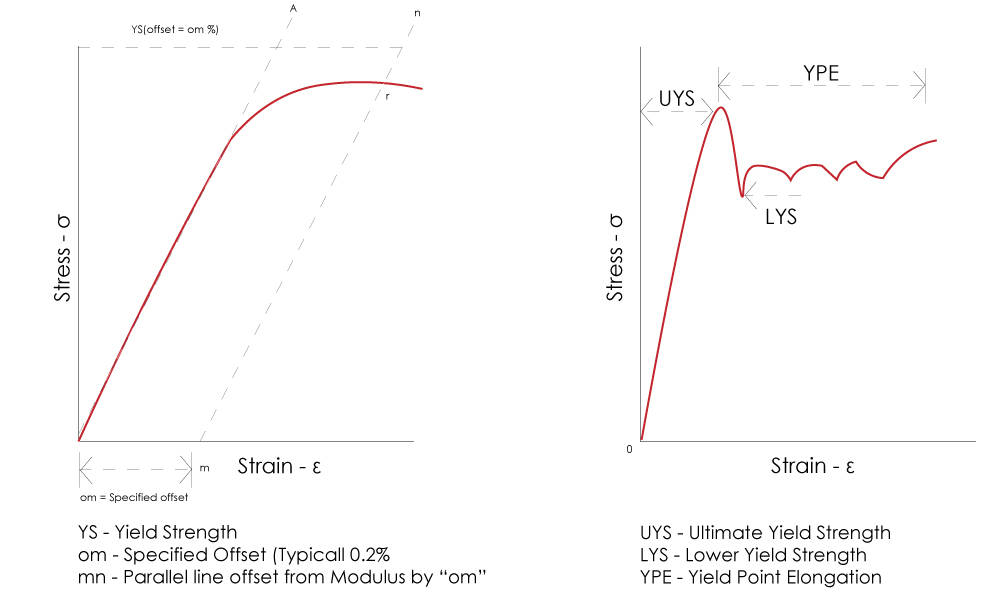

The calculation of yield is particularly important when testing metals. Yield in metals is typically calculated using the offset yield method, where a line is drawn parallel to the modulus and offset by a predetermined amount (the offset is expressed as a percentage and is determined by the ASTM or ISO standard being used). For metals, yield is generally calculated at 2% offset. In this case, the yield point is defined as being the point of intersection between the offset line and the stress/strain curve. This is only true for metals which exhibit continuous yielding, rather than discontinuous yielding, a phenomenon that occurs on certain alloys due to localized yielding.

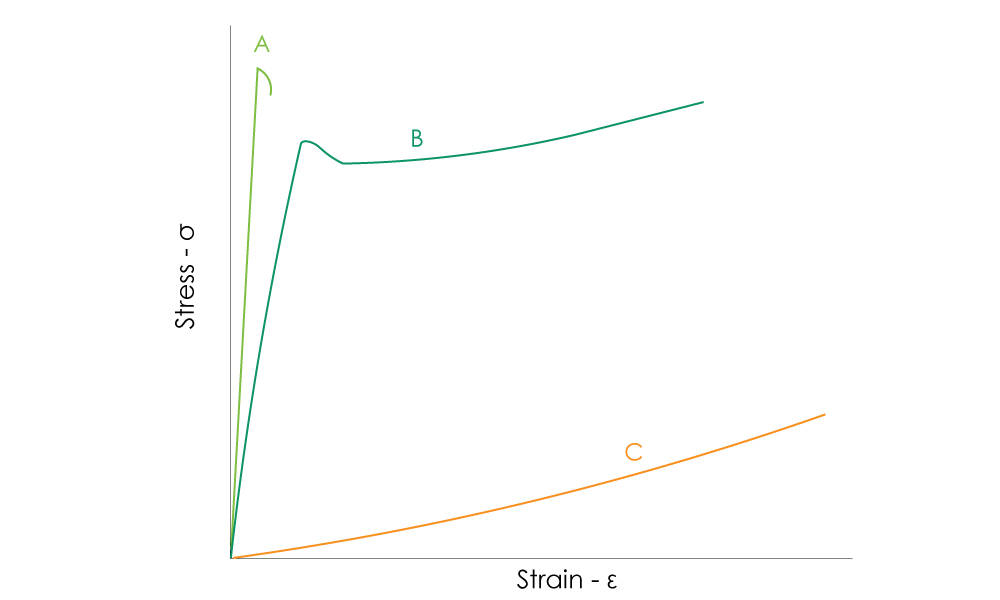

Not all materials exhibit yield. Composites and ceramics both fail at very low strains without exhibiting yield. Plastics and Elastomers can exhibit many different types of stress strain curves, but most will fall into one of three categories, only one of which exhibits a true, measurable yield point.

A: A brittle material which will break without yielding, such as a filled plastic material.

B: A material that exhibits a zero-slope curve, like many thermoplastics.

C: An elastomeric material which will slowly increase the applied load until failure, such as silicone rubber.

3400 Series Universal Testing Systems Brochure

Instron 3400 Series universal testing systems for tensile, compression, bend, and other material property tests.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability