Site Preparation Guidance and Services

Additional Installation Services

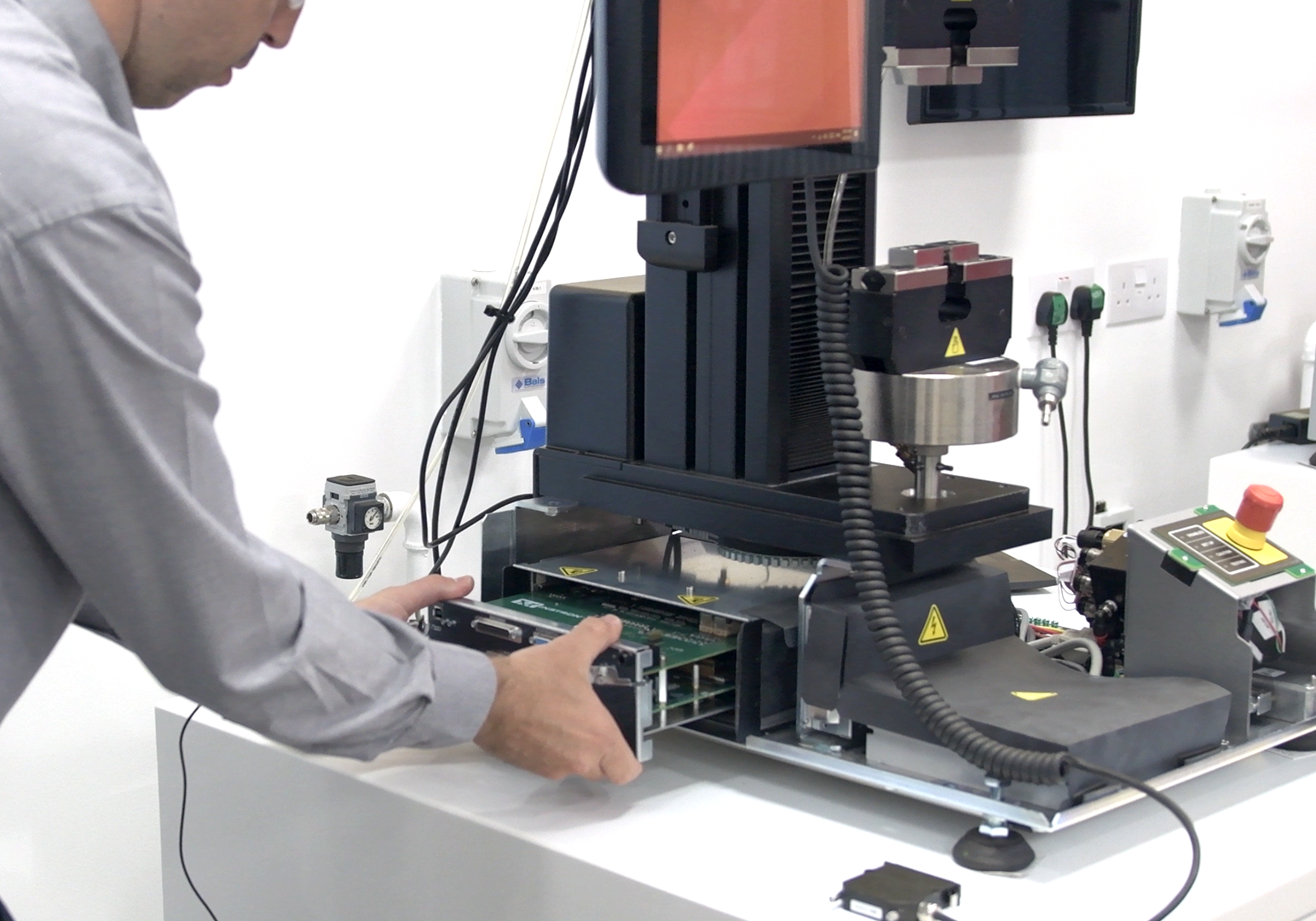

Calibration and Preventative Maintenance

We will review your current calibration and preventative maintenance cycle. If you purchase calibration services along with the system installation, these services will be performed at the same time.

Installation Training

Training at the time of installation will include the basic operation of the machine and software fundamentals. Our more complex software solutions include in-depth programming training that can be scheduled close to or at the time of installation.

Calibration and IQOQ After Software Upgrades or Updates

Calibration

Based on our software verification and validation testing during product development, we believe that software upgrades have no effect on the values of transducer calibration and data collected by the testing system. If your internal standards or compliance to other regulatory bodies (including those outside of ISO or ASTM) require you to recalibrate your testing instrument after a software change, we recommend a more comprehensive validation.

IQOQ

IQOQ validation is required for compliance with certain regulatory standards. If your system is governed by an IQOQ validation, you will need to evaluate whether any

revalidation is necessary after a software update or upgrade. This evaluation will likely include an analysis of what items have changed in the software and a risk assessment of how those changes affect your internal testing. If it is determined that a redo of the Instron IQOQ is required, please contact your local Service Team.