ASTM C880 Flexural Strength of Dimension Stone

Dimension stone used in the construction industry requires testing for flexural strength. As the Standard Test Method for Flexural Strength of Dimension Stone, ASTM C880 provides detail on the required test specimens and fixturing to determine the flexural strength.

The requirements of ASTM C880 include the following machine specifications & specimen preparations:

- Apparatus-Test machine capable of compressive loading as well as 4-point load fixturing. This fixture includes bearing support blocks to ensure vertical loading of the dimension stone specimens. The span length and distances between the load and support blocks must be constant within ± 0.05 inches

- Test Specimens-Samples are to sawed and finished-ground to dimensions of 4" x 1.25" x 15". A fine abrasive finish on planes perpendicular to the load along with fine saw finish on all other planes are required. A minimum of five specimens shall be tested for each specific condition of test.;

- Measuring specimens-Lower support span is to be 12.5" along with an upper support span set at 6.25".

- Conditioning-The dimension stone can be tested in both dry and wet conditions

- Dry specimens for 48 hours at 140 ± 4º Fahrenheit

- Wet specimens must be immersed in water for 48 hours at 72 ± 4º Fahrenheit

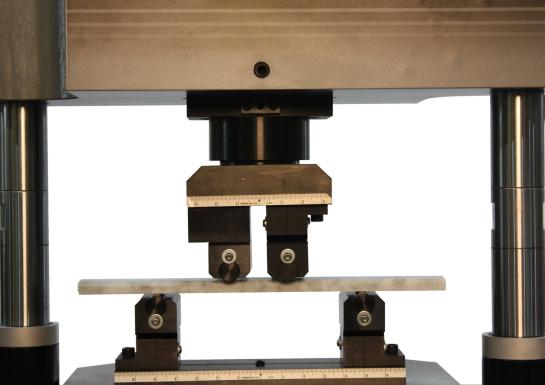

In order to test for flexural strength, we chose our Industrial Series 600DX Hydraulic Universal Testing Machine with compression-only capability. This machine includes an adjustable crosshead with mounting features to accept and center the upper portion of the flexural test fixture. In addition, the machines includes a table which permits the centering of the lower portion of the fixture. Instron designed the required fixturing to provide two lower supports (1" diameter) and two upper load applying blocks (1" diameter) for 4-point loading according to ASTM C880 specifications.

We recommend Bluehill Universal software as the user interface so the operator can easily set up the test, control test rates and get quick, accurate results after the test. The software is able to perform all of the data analysis required by ASTM C880 after the test is complete and displays the results on the screen for the operator to evaluate. The results and data are also stored in an Access database for later retrieval and access via a network.

We recommend reading and reviewing ASTM C880 in order to fully understand the test set up, procedures, and results requirements.

Industrial Series DX Models

Designed for high-capacity tensile, compression, bend/flex, and shear testing, DX Series testing systems feature a dual test space and single footprint. Understanding the critical importance of operator safety, these frames incorporate high-quality materials, components, and craftsmanship and are ideal for testing metals, wire rod, fasteners, concrete, and wood.

- Products

- 08/29/2022

- 1.03 MB