The Definitive Guide to ASTM D1002 Lap Shear Testing of Adhesively Bonded Metals

ASTM D1002 describes the procedure for evaluating the shear strength of adhesives used for bonding metals. These adhesives are commonly used in the automotive, aerospace, and electronics industries to bond various joints and subcomponents. Adhesive testing is critical for understanding the relative strength of different materials, as well as identifying the effects of environmental conditions and aging on the strength and durability of a bond. This guide will discuss the test equipment required to perform ASTM D1002, however, anyone planning to conduct testing to this standard should not consider this guide an adequate substitute for reading the full standard.

What Does it Measure?

ASTM D1002 is intended to be primarily comparative in nature, as the performance of an adhesive in a controlled test environment and single lap shear specimen geometry cannot be correlated to real world performance. In real world applications, changing environmental conditions and non-uniform joint geometries, among other things, contribute to the variation of adhesive performance.

Specimens

Properly testing an adhesive’s strength requires the use of a substrate. In the case of ASTM D1002, this substrate is metal. The specific types and grades of metals acceptable for testing are referenced in section 6.4 of the standard. Specimens are prepared in a single lap shear geometry, where two identical pieces of substrate have a defined overlap section which are adhered using the adhesive being tested.

Test Control and Modes of Failure

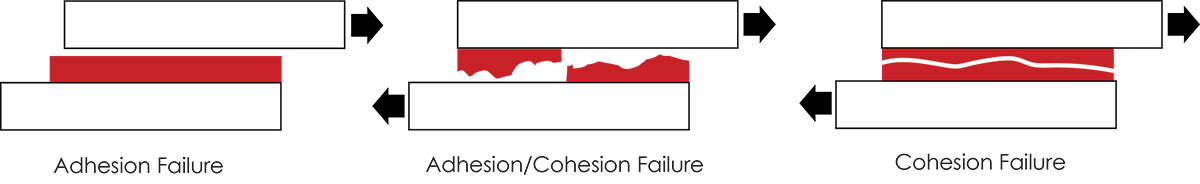

ASTM D1002 is performed by pulling the two ends of the adhered specimens in tension until failure. The tensile force applied to the specimen translates into a shear stress applied to the entire adhered area. The results will include the failure load, often expressed per unit shear area as well as the nature of the failure. Typically, this can be recorded as one of the following three failure types:

- Cohesion of adhesive - the failure occurs within the adhesive

- Adhesion to substrate - the failure occurs at the bond between the adhesive and the substrate

- Combination failure - the failure occurs within both the adhesive and adhesive-substrate bond

ASTM D1002 requires the use of either a constant stress rate or equivalent displacement rate. The stress rate is performed using a closed loop feedback between the test system's load cell and controller. The PID settings for the load cell may need to be adjusted to achieve the desired stress rate within a reasonable error band. Many customers use the equivalent crosshead displacement rate to simplify the testing.

Material Testing System

Most ASTM D1002 lap shear testing is commonly performed on a single or dual-column universal testing machine like Instron's 3400 Series and 6800 Series systems. The load capacity of the system is dependent on the strength of the adhesive, typically ranging between 1 kN and 30 kN.

| ASTM D1002 Test Setup | |

|---|---|

6800 Series universal testing system |

|

Bluehill Universal software |

|

2580 Series load cell |

|

2710 Series side-action grips |

|

Gripping Solutions

The main challenge associated with single lap shear testing is load string alignment. The geometry of the test specimen causes the two clamped ends of the specimen to be offset from one another. Significant side loading can occur if the gripping solution does not account for that offset, potentially causing premature failures and faulty data. Instron's 2710-11X Advanced Screw Action Grips and 2712-04X (5 and 10 kN Capacities) Pneumatic Side Action Grips both have integrated offsets which allow you to manually adjust the jaw faces to the left or right. This functionality helps the operator ensure that the center line of the applied force coincides with the center line of the load string. Manual Wedge Grips can also be utilized with the addition of spacer blocks in between the grip body and the jaw face. These spacers will compensate for the offset, though many of them will be required if testing multiple specimens with different substrate thicknesses.