ASTM D1037 Internal Bond Testing of Fiberboard and Wood Adhesives

ASTM D1037, the Standard Test Method for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials, outlines multiple testing procedures to characterize the mechanical properties of fiberboard. The internal bond test procedure is outlined in section 11 of the ASTM D1037 standard, though other sections also evaluate fastener holding, flexure properties, and compression properties in ambient or simulated environmental conditions.

Wood fiberboard is an engineered material made by using an adhesive to glue wood chips or wood particles together under high pressure, and the internal bond test of ASTM D1037 ensures that the cohesion strength of the engineered panel is sufficient for a given application. The internal bond test measures the tensile strength of the material when applying a force perpendicular to the face. This testing is especially important considering that these materials are used in construction applications and many of them are formed through the adhesion of multiple layers of material.

Materials Testing System

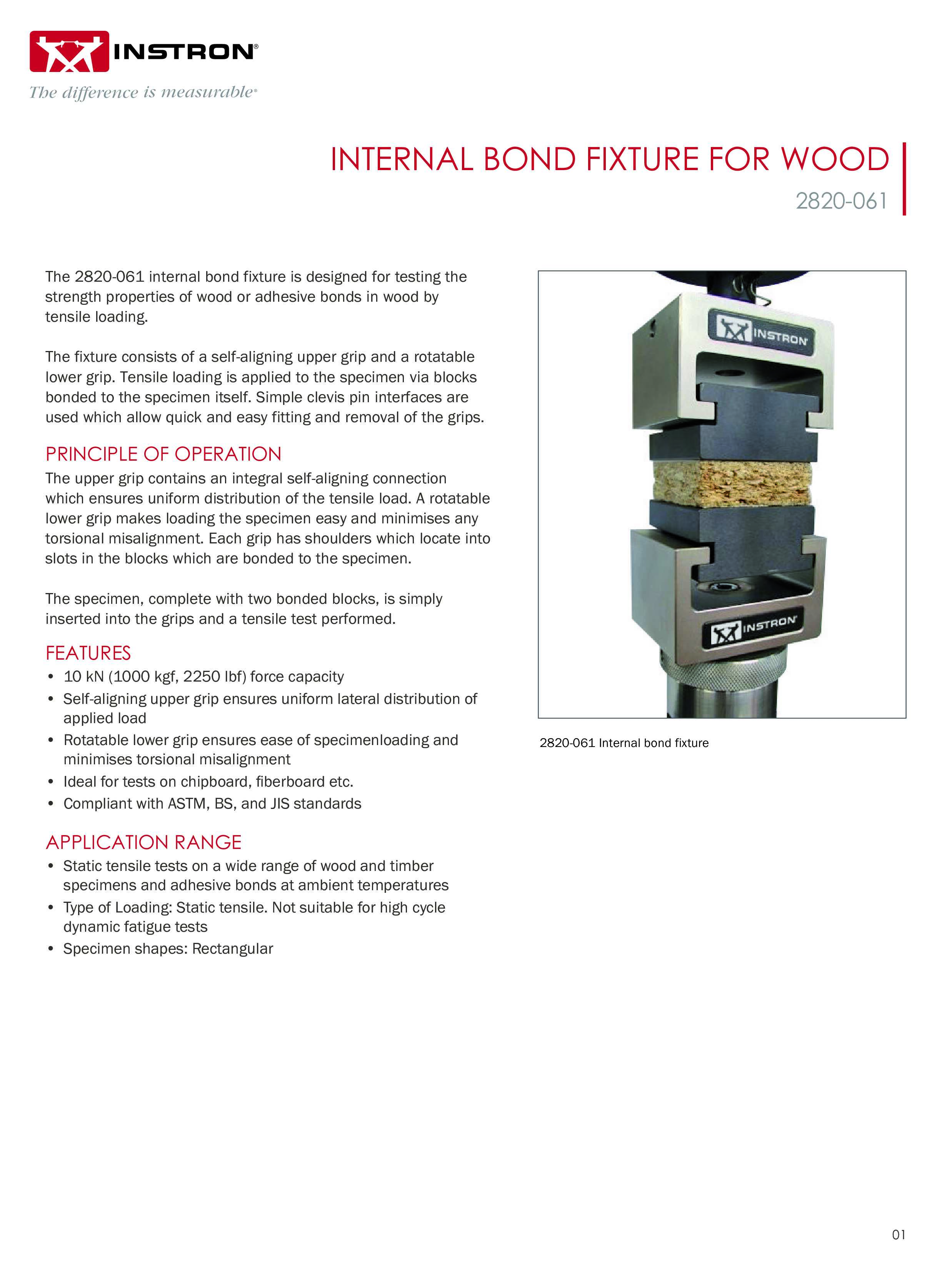

Most ASTM D1037 force requirements are suitable for a dual column universal testing system such as those found in Instron's 6800 and 3400 Series. Required fixtures include Instron's 2820-061 internal bond test fixture and 2820-062 steel specimen blocks, which were designed in compliance with the requirements of this standard.

| ASTM D1037 | |

|---|---|

| 1) | 6800 Series Universal Testing System |

| 2) | Bluehill Universal Software |

| 3) | 2580 Series Load Cell |

| 4) | 2820-061 Internal Bond Fixture for Wood and Fiberboard |

ASTM D1037 Test Fixtures

The principle of ASTM D1037 internal bond testing involves bonding specimen blocks to the top and bottom surfaces of the test specimen with a suitable adhesive. The loading block bond must be stronger than the expected failure force of the specimen. The upper loading fixture should be self-aligning, and the specimen blocks should be 2-inch square by 1-inch in thickness and made from steel or aluminum alloy. Instron’s 2820-061 and 2820-062 fixtures have been designed in compliance with these requirements.