ASTM D1894 Coefficient of Friction of Plastic Film

ASTM D1894 is a standardized test method used for determining static (μ_s ) and kinetic (μ_k ) coefficients of friction of plastic film and sheeting. Plastic film is a widely used material in the packaging industry and includes many types of food packaging (produce bags, carton liners, meat seal wrap) and non-food packaging (envelope liners, potting soil sacks). Plastic films are also key components of more complex products, such as electric vehicle batteries. In order to ensure that they perform as expected for the end user, the frictional properties of these films must be characterized and controlled.

Standard At A GlanceMaterials

- Plastics

Test Types

- Peel, Tear, and Friction

Standard

- ASTM D1894

- ISO 8295

Separator films are used in EV battery production to separate the anode and cathode in lithium-ion and other liquid electrolyte batteries. These films are required in high volumes and are extremely critical to product safety. Because testing standards specific to EV batteries have not yet been established, ASTM D1894 is commonly used as a proxy standard to characterize their frictional properties. The most common material used for separator film is polyolefin, a polymer film that is strong enough to withstand the winding operation during assembly as well as uneven plating of lithium on the anode due to extensive use. Safer and stronger separator material more effectively prevents contact between the anode and cathode, while thinner material helps reduce the weight of each battery and improve energy density. Understanding the frictional properties of this polymer film can help ensure the material is being wound properly during assembly and will behave as expected under extensive use.

Materials Testing System

When testing thin films to ASTM D1894 it is important to use a test machine with a high data capture rate. Because test events can happen quickly, a machine with a low data capture rate may miss key peaks and troughs in the data, leading to an inaccurate average strength value. Instron’s 6800 Series test frames are capable of data capture up to 5 kHz to ensure that all test events are captured. For ASTM D1894 testing we recommend a 6800 Series single column frame equipped with a low force (5 – 100 N) 2530 Series load cell (depending on the expected frictional forces).

| ASTM D1894 Test Setup | |

|---|---|

6800 Series Universal Testing System |

|

Bluehill Universal Software |

|

2530 Series Load Cell |

|

2810-005 Coefficient of Friction Fixture |

|

HOW TO PERFORM A TEST TO ASTM D1894

This test requires the use of Instron's 2810-005 coefficient of friction fixture, which is specifically designed to meet the requirements of ASTM D1894 and ISO 8295. The film under test is secured on a flat surface and a sled of known weight is wrapped in the same material. The motion of the crosshead drags the sled along the film being tested and the force measured is used to determine both the static and kinetic coefficients of friction. Complete details on how to perform this test can be found by reading the full ASTM D1894 standard.

Tips and Tricks

- Instron’s 2530 Series load cells can maintain accuracy down to 1/500th of the cell’s capacity when used on a 6800 Series universal testing system. The lowest capacity 2530 series load cell is 5 N, meaning it can maintain 1% accuracy from 0.02 N to 5 N. Forces beneath the lower limits can be measured, but Instron cannot guarantee stated accuracy.

- Instron's Bluehill Universal testing software has advance pre-built methods available for ASTM D1894 to ensure that your test speeds and calculations are compliant.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

2810-005 Coefficient of Friction Fixture

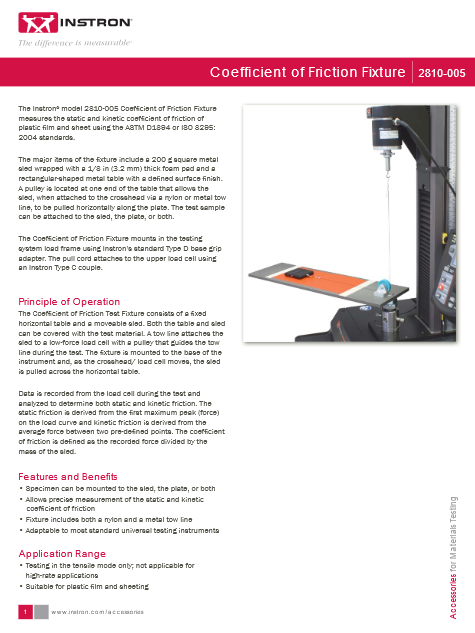

The Instron® model 2810-005 Coefficient of Friction Fixture

measures the static and kinetic coeffi cient of friction of

plastic fi lm and sheet using the ASTM D1894 or

ISO 8295:2004 standards.

2580 Series Static Load Cells Data Sheet

The 2580 Series load cells are specifically designed for use with 6800 and 5900 testing systems; offering exceptional performance with the ability to measure forces as low as 1/1000th of the force capacity to an accuracy of 0.5% of reading.

2530 Series Low Force Load Cells

Instron 2530 Series low force static load cells range in capacity from 5 – 100 N and are designed for use with 3300, 3400, 5900, and 6800 Series universal testing systems.