ASTM D3846 In-Plane Shear Strength of Reinforced Plastics

ASTM D3846 describes the method for determining the in-plane shear strength of reinforced plastic composite materials. These specimens are typically thermosetting plastics with reinforcements that widely vary in type and thickness ranging from 2.54 mm to 6.60 mm.

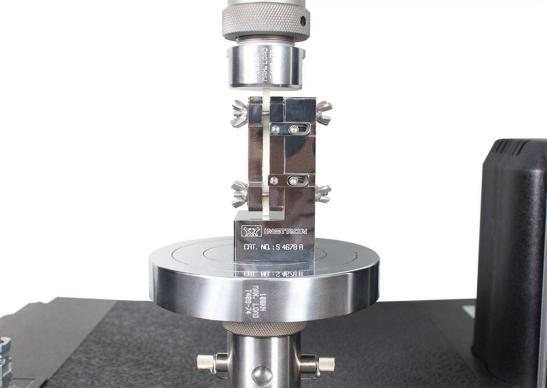

The test method is similar to that of ASTM D695-15 Test Method for Compressive Properties of Rigid Plastics, except that in the ASTM D3846 method, failure of the specimen occurs in shear between two centrally located notches that are machined halfway through the thickness of the specimen and spaced a fixed distance apart on opposing faces. For this test, we recommend a 6800 Series universal testing system.

- Ensuring parallelism of compression platens

- Reporting calculations in compliance with the standard

Our solutions:

- Ensuring parallelism of compression platens – When testing according to ASTM D3846, the compression platens must be parallel to each other and in the normal plane to the axial loading. The lockable spherically-seated platens provide a means of pre-loading the assembly and locking the platen to ensure parallelism for the test.

- Reporting calculations in compliance with the standard – In order to calculate the in-plane shear strength, the user must measure the length of the failed area. Bluehill® Universal materials testing software offers a prompted test to walk users through the necessary inputs at each step. An integrated specimen measurement device can be used to automatically input the measurements into Bluehill Universal, saving time and eliminating typos.

It is important to review ASTM D3846-08(2015) in order to fully understand the test setup, procedure, and results requirements.

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

- Products

- 02/26/2017

- 3.76 MB

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

- Products

- 02/10/2020

- 1.93 MB

Specimen Measurement Devices Data Sheet

Instron® testing systems provide an accurate measurement of force during a test, but in order to produce accurate stress results, you must measure the specimen and get the dimensional data into Bluehill® Universal Software. While digital instruments, such as micrometers, can provide accurate measurements, using them properly takes time and requires the operator to manually enter the dimensional data into the software.

- Products

- 12/11/2017

- 620.02 KB