ASTM D429 Rubber Property - Adhesion to Rigid Substrates

ASTM D429 determines the adhesion strength of rubber to rigid materials, such as metals. The standard requires that the testing machine conform to practices described in ASTM E4. Our 3400 and 6800 Series universal testing systems meet this specification and provide an appropriate solution for this test application.

The standard calls out several test types related to rubber adhesion strength; however, Methods A and B are the most common.

- Method A describes a tension test used to determine the bond of a rubber part assembled between two parallel metal plates.

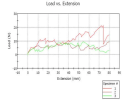

- Method B describes a peel procedure to determine the adhesive strength between rubber materials to a metal plate or substrate. The value of interest is the "Adhesion Strength" defined as the maximum force divided by the width of the specimen.

The challenges of testing to this standard:

- Accurately tracking the peaks and troughs throughout the adhesion test in order to report precise results.

- Maintaining unidirectional force throughout the process of peeling from a substrate.

- Proper specimen gripping.

Our solutions:

- Bluehill Universal® software can calculate adhesion strength values per this test method. Adjustable data acquisition rates allow the user to ensure they are capturing all the desired peaks and troughs throughout the entire test. (Methods A and B)

- We recommend using a specialized fixture that holds and moves the substrate as the rubber strip is peeled off by an upper grip. (Methods B)

It is important to review ASTM D429 in order to fully understand the test setup, procedure, and results requirements.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

- Products

- 02/10/2020

- 1.93 MB

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

- Products

- 02/26/2017

- 3.76 MB

2712-04X Series Pneumatic Side-Action Grips

Pneumatic side-action grips offer a versatile gripping solution for a wide range of materials. Rated capacities between 1 and 10 kN.

- Products

- 03/22/2022

- 1.13 MB

2710 Series Screw Side Action Grips

Screw side‑action grips offer a straightforward and reliable way to secure test specimens across a wide range of applications. The dual‑acting design of the 2710‑100 series allows the jaw faces to adjust easily for different specimen thicknesses, keeping the tensile load path centered within the grip body. These grips support a variety of interchangeable jaw faces in multiple sizes and surface types, including smooth ground, rubber‑coated, serrated, line‑contact, and specialty coated options. A convenient snap‑on attachment system makes swapping jaw faces fast and hassle‑free, adding flexibility for diverse testing needs.

- Products

- 06/28/2017

- 1.29 MB