ASTM D7192 High Speed Puncture Properties of Plastic Film

The test method ASTM D7192-08 covers the determination of puncture properties of plastic films over a range of test velocities. The materials covered by this standard are to have a thickness not greater than 0.25 mm (0.010 in) and to be non-rigid as defined by section 3.2.1 of the standard. The test outlined in the standard is designed to provide load versus deformation responses of plastic film under multi-axial deformation conditions at various impact velocities. By testing at various impact velocities a measure of the rate sensitivity of the film to impact events may be gathered. Recommended in the test standard are speeds of 2.5, 25, 125, 200 and 250 m/min. (0.137, 1.367, 6.835, 10.936 and 13.670 ft/s).

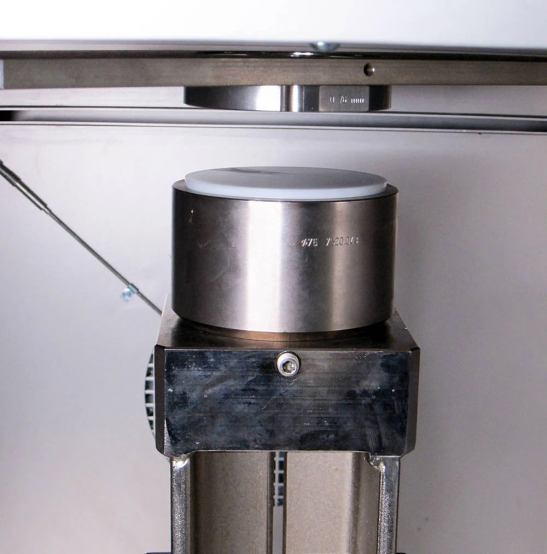

The machine used for the test shall consist of two assemblies, one fixed, the other driven by suitable method to achieve the required impact velocity, a specimen clamping assembly with rubberized surface to avoid any slippage and an unsupported region of 76 ± 3.0 mm (2.992 ± 0.118 in.) The film shall be held taut but not stretched so tightly as to cause damage to the specimen prior to test. A minimum of five specimens shall be tested at each specified speed with a plunger assembly consisting of a 12.70 ± 0.13 mm (0.5 ± .005 in) diameter rod with a hemispherical end of the same diameter.

When asked to offer a testing solution to this standard we recommend the use of an Instron 9400 Drop Tower, like the 9440 to reach impact speeds up to 4.65 m/s or 9450 to have a wider range of impact velocities.Our thin film hoops ensure that the film is pulled taut over the unsupported region prior to impact. We are used to recommend a 0.45kN or 4.5kN load cell depending on films strength and failure type.

Data Acquisition system, Touchscreen controller and Bluehill Impact software provide the means for measuring and recording the load, displacement and velocity of the test event simultaneously. In addition values for energy at peak load and total energy absorbed are provided.

9400 Series Drop Tower Brochure

Instron Drop Towers are used to develop, fine tune, and validate material models. Testing materials under real impact conditions is a crucial step prior of product design. Using the characterization data obtained with the Instron 9400, coupled with customer supplied high-speed video, you can have confidence in your results and deliver new materials to your customers faster. Our Drop Tower impact systems, fixtures, and tups are designed to meet a wide range of applications and testing standards including: ISO, ASTM, ANSI, Airbus, Boeing, BSI, DIN, EN, FDA, Ford, GM, JIS, NASA, GOST, and more.

- Products

- 02/05/2020

- 763.1 KB

9400 Series Dashboard Brochure

Bluehill® Impact is built from the ground up for touch interaction. The Operator Dashboard features large touchpoints to make the user experience simpler and smarter. Easy-to-understand icons and workflows make it easy to train new or experienced users, simplify operator training, and allow you to start testing even faster than ever before

- Products

- 08/01/2019

- 2.35 MB